I forgot to mention that your post is very human. Thank you. Can you share more specifics about what Mr. Bradley said about this steel?Cliff Stamp wrote:In a YT video, Bradley made a comment about PSF27 regarding "grain size" and how it influenced carbide tearout. In particular, since it was spray formed but not HIP had a stronger resistance to carbide tearout. He then went on to say the reason why this happens was due to the shape/size of the carbides and the larger "grain" size.

A question was asked about this (on the forum) from a metallurgical perspective because a larger austenite grain size is strongly known (materials data) to reduce strength and toughness and as well (Landes work) apex stability directly. A bit of a concern in these discussions is what people mean by grain size because as me2 is fond of pointing out people often refer to both the size of the carbides and the size of the austenite as "grain size".

I called Mr. Bradley to ask him about this and we spoke for quite some time. We spoke about his experience with PSF27 vs ingot and HIP steels. How he sharpened them, how he sharpened in general and many other things. It was clear immediately that he wasn't making the argument that PSF27 resisted carbide tearout better because of the metallurgical reasoning he made in that video, but his evidence was that he saw it. The metallurgy was just an attempt to explain why it happens, not as an argument as to that it happens, two very different arguments.

As to the metallurgy, it is an interesting question/point and the first time I have heard an argument that not HIP'ing a steel would enhances its performance (as it is known to decrease porosity for example). Generally the reason that spray forming tries to avoid HIP is because it is expensive, hence the research into how to spray form to achieve a high density. I have asked a bunch of people in the field (who do that work) do they have any data and have been looking for it myself. No luck so far to support or deny Bradley's hypothesis.

The point of this post however was simply to note respect/admiration for someone who would actually answer questions and provide justification for his claims. At no point in the conversation was Bradley upset or even irritated that I didn't simply accept something because he said it and he actually was interested that I wanted to know why he asserted it, what was his evidence and he was happy to provide it and to share what he knew with someone who wanted to learn/understand.

As I can come across (shocking) as a bit critical of makers, I thought it only fair to note this kind of thing for which I hold in high regard. At the end he asked if I understood it or was I just confused and I ended with confusion is a good thing anyway because the minute you are not confused you are not trying to learn. The unknown is always confusing, if it wasn't then it would be the known. I will be picking up one of the Bradley PSF27 collaborations for no other reason than to support that behavior as if you don't support what you argue should be done it is pointless to argue for it.

A conversation with Gayle Bradley - PSF27

Re: A conversation with Gayle Bradley - PSF27

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

At times I might give off the impression that steels are all very similar, and in some respects they are. The differences between them are certainly at times so small that there is no way to see differences practically. In most cases when people are talking about a difference between something like ATS-34 vs S30V they are either seeing something that isn't there and is just a bias, or they are seeing something which isn't due to the steel but for example the geometry.KevinOubre wrote:...what then is the purpose of different steels in knives?

This question, like many of the ones you asked generates controversial answers because lots of people claim they can see those differences, does what I said mean they are all lying and there is an evil plot of disinformation? No, it means that most people don't do empirical work with methods that generate knowledge and thus a lot of what comes out simply isn't true. This isn't just about knives, people say all kinds of things because in general we are willing to reach very strong conclusions on sparce data.

For example racism is an extremely insensible conclusion. Just think about how valid this argument is really :

-I have seen a rabbit, it is white

-All rabbits therefore are white

Even a child knows the conclusion doesn't follow - but people make these kinds of conclusions all the time. Even I do it and I know it is wrong. For example I have a pretty severe bias against Pentel leads because three times in a row I bought them and the leads were multiple broken in the container and the ones which were not were easy to break. Not on some level I know this is just statistics, if you look at anything long enough you get those kinds of runs. However on a deeper level my brain says nuts to your logic and concludes Pentel makes horrible leads. I thus react one way, and have to force myself to over ride it because the data simply don't show that, there is not enough statistical power in the same, the conclusion is not justified.

There are two things :How do we account for the dramatic edge retention accounts from numerous people in the industry regarding steels like S110V, ZDP-189, M4, etc?

-lack of empirical rigor

-lack of understanding of the nature of blunting

-lack of clarification of what exactly is being done

Years ago, once I determined the function which governs how edge retention happens and realized it was strongly nonlinear I noted immediately that these two comparisons, which might look similar, give completely different results :

-cut until the blades are 5% of optimal sharpness and compare amounts of material

-cut a specific amount of material and compare sharpness

If you ask people about those results (just try) most people will think they would give similar ratios, however they are not even in the same magnitude and here is why :

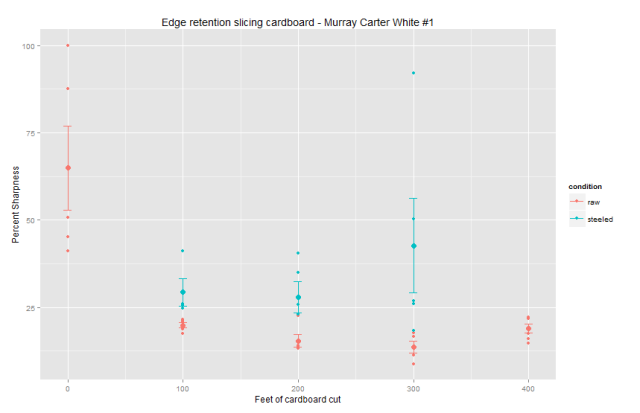

That is some data from Ian who is doing an experiment similar to one I did on steeling. Note the very strong nonlinear response and how slow the data changes in the tails. I have even done the math and showed that you need extreme precision, and for example that if you can't measure sharpness to 1% then the final results can swing by things like double the amount of cuts. It is just basic math, but yet people will claim things like 175 vs 205 cuts. It simply can't be done. Again this seems controversial, but the data is clear, even the CATRA data show up to 20% swings in the results. What do you think a hand trial should generate. Here is the raw truth - if the results claim much greater precision they are simply showing user bias and data manipulation. The math is high school statistics.

There are a lot of makers doing a lot of great work. What I look for in dealing with such people isn't as much what they do but are they willing to discuss it and think about it. This is what generates knowledge, modification through feedback, correction which leads to convergence.Has the whole industry taken a wrong turn with their testing protocols?

I think that is a good question, I think there are a number of factors :Do you think the relatively thick edge preferences of most people account for the performance of higher carbide steels verses the simpler steels?

-on expensive knives even small amounts of damage can be a big deal so durability gets a really strong emphasis

-people often don't know what high cutting ability actually means

-in general expectations are often met with fairly low standards

-

KevinOubre

- Member

- Posts: 111

- Joined: Tue Sep 30, 2014 6:55 pm

- Location: Baton Rouge, Louisiana

Re: A conversation with Gayle Bradley - PSF27

Cliff Stamp wrote:At times I might give off the impression that steels are all very similar, and in some respects they are. The differences between them are certainly at times so small that there is no way to see differences practically. In most cases when people are talking about a difference between something like ATS-34 vs S30V they are either seeing something that isn't there and is just a bias, or they are seeing something which isn't due to the steel but for example the geometry.KevinOubre wrote:...what then is the purpose of different steels in knives?

This question, like many of the ones you asked generates controversial answers because lots of people claim they can see those differences, does what I said mean they are all lying and there is an evil plot of disinformation? No, it means that most people don't do empirical work with methods that generate knowledge and thus a lot of what comes out simply isn't true. This isn't just about knives, people say all kinds of things because in general we are willing to reach very strong conclusions on sparce data.

For example racism is an extremely insensible conclusion. Just think about how valid this argument is really :

-I have seen a rabbit, it is white

-All rabbits therefore are white

Even a child knows the conclusion doesn't follow - but people make these kinds of conclusions all the time. Even I do it and I know it is wrong. For example I have a pretty severe bias against Pentel leads because three times in a row I bought them and the leads were multiple broken in the container and the ones which were not were easy to break. Not on some level I know this is just statistics, if you look at anything long enough you get those kinds of runs. However on a deeper level my brain says nuts to your logic and concludes Pentel makes horrible leads. I thus react one way, and have to force myself to over ride it because the data simply don't show that, there is not enough statistical power in the same, the conclusion is not justified.

There are two things :How do we account for the dramatic edge retention accounts from numerous people in the industry regarding steels like S110V, ZDP-189, M4, etc?

-lack of empirical rigor

-lack of understanding of the nature of blunting

-lack of clarification of what exactly is being done

Years ago, once I determined the function which governs how edge retention happens and realized it was strongly nonlinear I noted immediately that these two comparisons, which might look similar, give completely different results :

-cut until the blades are 5% of optimal sharpness and compare amounts of material

-cut a specific amount of material and compare sharpness

If you ask people about those results (just try) most people will think they would give similar ratios, however they are not even in the same magnitude and here is why :

That is some data from Ian who is doing an experiment similar to one I did on steeling. Note the very strong nonlinear response and how slow the data changes in the tails. I have even done the math and showed that you need extreme precision, and for example that if you can't measure sharpness to 1% then the final results can swing by things like double the amount of cuts. It is just basic math, but yet people will claim things like 175 vs 205 cuts. It simply can't be done. Again this seems controversial, but the data is clear, even the CATRA data show up to 20% swings in the results. What do you think a hand trial should generate. Here is the raw truth - if the results claim much greater precision they are simply showing user bias and data manipulation. The math is high school statistics.

There are a lot of makers doing a lot of great work. What I look for in dealing with such people isn't as much what they do but are they willing to discuss it and think about it. This is what generates knowledge, modification through feedback, correction which leads to convergence.Has the whole industry taken a wrong turn with their testing protocols?

I think that is a good question, I think there are a number of factors :Do you think the relatively thick edge preferences of most people account for the performance of higher carbide steels verses the simpler steels?

-on expensive knives even small amounts of damage can be a big deal so durability gets a really strong emphasis

-people often don't know what high cutting ability actually means

-in general expectations are often met with fairly low standards

Thanks for the clarification Cliff. Like you said, learning is what's important.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

This might be an odd approach but I was more concerned about what he had done, his justification or reasoning than his conclusions. This is because making a conclusion is the easiest thing in the world, however actually having a warrant for it is difficult. I wanted to understand how he approaches a conclusion, why he would think a thing to be true and that was mainly what I asked about. Now he did provide a lot of details about the steel, the main point was that he has found PSF27 to strongly resist carbide tearout as he noted in the video and in general he speaks very favorably about it. I don't want to imply I am holding things secret or anything, just that I mainly focused on what he did which lead him to assert what he does more so than the conclusions he reached.Bodog wrote:[...] Can you share more specifics about what Mr. Bradley said about this steel?

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

Yes, I'll give you an example of what I think is a productive approach.KevinOubre wrote:Like you said, learning is what's important.

Joe Calton had made on BF and other places some strong statements about the performance of his 1095 in regards to rope cutting ability. I called shenanigans on it due to the extent of the claims. A guy had one of his knives and sent it to me, Joe found out about it and sent along with it (it was ordered) some of the rope he uses, an old sharpener than he uses (worn down diamond) and then we exchanged notes on his exact results. I thus had one of the exact knives he used, the rope and even the sharpening stone. Now was Joe upset I was going to attempt to duplicate his claims - of course not, that is what science it about, why would you ever not want someone to confirm what you said was true?

I did the work, what he said was true and we then discussed the steel and the reasons for it are really clear. He grinds to very thin edges and I mean almost true zero so you can cut 1/2" hemp with 4-5 lbs on a 2" draw. This force is so low that it takes a LOT of rope to get to 10-15 lbs which is where a lot of people like Wilson start cutting with a freshly sharpened blade. But Joe's blade is in the tail end of the blunting then so it blunts very slow from that point. He also uses a semi-coarse edge, low edge angles and hardens the 1095 so as to produce an ultra-fine grain and a high hardness. He uses the same methods that I have noted in the literature here of multiple quenching where the carbides in 1095 nucleate the austenite grain and through repeated cycling produce a very fine grain and thus much higher strength and toughness at a given hardness.

Re: A conversation with Gayle Bradley - PSF27

Its hard for me to explain but I feel the PSF27 gets that numb edge that cuts really well, and S30V gets that screaming edge loud more aggressive in a way. As far as sharpening I think to get a good edge on a PSF27 takes longer than on S30V but once you get it there it sticks around. Both are kind of more difficult to sharpen compared to vg10 or H1. I haven't touched my GB M4 or my manix2 S110V as far as real sharpening or changing an angle. But I did compare it to the Cru Wear one of my favorite steels and they cut about the same but the Cru Wear glides faster. I think PSF27 is a good steel for outdoor use bushcraft knives(no scandi) and uses similar to that genre. I am not very experienced with sharpening I only use DMT plates/spyderco sharpmaker and some strops for my sharpening needs. Don't have any super fine grit Japanese water stones or high end stones like that. I hope my explanation was understandable.Cliff Stamp wrote:How do you find it compares to PSF27?opusxpn wrote: ... I have s30v

Keep'em sharp :spyder: 9 Enduras, 4 Manix, Manix XL DLC, 3 Delicas, 5 Ladybug, 2 Manbug, 4 Dragonfly, Pingo, Cat, 3 Salt1, Pacific salt, Tasman, 3 stretch, 2 Tenacious, Resiliance, Robyn2 G10, 2byrd hawkbill, 4Para2, 2Military, native5 frn, Bradley folder, SpyDK, Kiwi, MT19, salt saver, Street bowie, Roadie,Squeak, 5 UKPK, k05 SE, k04 SE & PE

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

That is interesting, are the geometries of those blades similar?opusxpn wrote:[... the PSF27 gets that numb edge that cuts really well, and S30V gets that screaming edge loud more aggressive in a way. As far as sharpening I think to get a good edge on a PSF27 takes longer than on S30V but once you get it there it sticks around. Both are kind of more difficult to sharpen compared to vg10 or H1.

Re: A conversation with Gayle Bradley - PSF27

PSF27 is noticeably harder to reprofile compared to an S30v millie. I sharpen off of relief bevels for both so sharpening is fairly quick.Cliff Stamp wrote:That is interesting, are the geometries of those blades similar?opusxpn wrote:[... the PSF27 gets that numb edge that cuts really well, and S30V gets that screaming edge loud more aggressive in a way. As far as sharpening I think to get a good edge on a PSF27 takes longer than on S30V but once you get it there it sticks around. Both are kind of more difficult to sharpen compared to vg10 or H1.

They who dance are thought mad by those who do not hear the music.

Re: A conversation with Gayle Bradley - PSF27

No my mule psf27 does not have a 30/40 like the other knives. It has a lower 30/35 or around there did free hand on my diamond plates. Went with lower angles not by much but lower. I might try to go lower to see what happens. Havent taken the time to do extensive testing on the knives I got. I just sharpen them to get them where I want them, just sharp enough to cut well. Need to figure out how to optimize an edge but every steel is different. All them steels like different angles and grits. The spray form steel must have a less toothy edge regardless of grit you sharpen with compared to S30v. The scratch pattern will be different and so will the cutting ability and endurance of the edge. I guess if I was to choose between s30v and psf27 I would choose the s30v because the edge does not need to be so refined to cut well.

Keep'em sharp :spyder: 9 Enduras, 4 Manix, Manix XL DLC, 3 Delicas, 5 Ladybug, 2 Manbug, 4 Dragonfly, Pingo, Cat, 3 Salt1, Pacific salt, Tasman, 3 stretch, 2 Tenacious, Resiliance, Robyn2 G10, 2byrd hawkbill, 4Para2, 2Military, native5 frn, Bradley folder, SpyDK, Kiwi, MT19, salt saver, Street bowie, Roadie,Squeak, 5 UKPK, k05 SE, k04 SE & PE

Re: A conversation with Gayle Bradley - PSF27

I guess I don't understand how this is possible. Given that you used diamond plates, which are much harder than any carbides in both steels, why would the scratch pattern be different (in a general way)? I am under the impression that physics dictates that the sharpening grit must make a difference in the "toothyness" of an edge, since the scratch patterns are incredibly larger than any grain/carbides.opusxpn wrote:The spray form steel must have a less toothy edge regardless of grit you sharpen with compared to S30v. The scratch pattern will be different and so will the cutting ability and endurance of the edge. I guess if I was to choose between s30v and psf27 I would choose the s30v because the edge does not need to be so refined to cut well.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

That is interesting, considering the high vanadium content than S30V. Do you find the same in regards to polishing?Bodog wrote: PSF27 is noticeably harder to reprofile compared to an S30v millie.

Is the edge thickness similar on both knives, are the bevel widths similar?

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

If the carbides are getting torn out, or the steel is fracturing or deforming to different extents, you can see a different apex finish at the same sharpening finish. Often though this tends to indicate problems in the steel more so than anything else. For example if a steel is gummy or if it isn't hardened properly and is over brittle and it can fracture larger than the scratch pattern.tvenuto wrote:... why would the scratch pattern be different (in a general way)?

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

I would be interested to see if your views on the performance aspects you noted were similar if the edges were of similar thickness/angle as those two aspects have strong influences on sharpening as well. In particular a wider edge bevel has a significant reduction on sharpening efficiency.opusxpn wrote:No my mule psf27 does not have a 30/40 like the other knives. It has a lower 30/35 or around there did free hand on my diamond plates.

Re: A conversation with Gayle Bradley - PSF27

Millie is thicker.Cliff Stamp wrote:That is interesting, considering the high vanadium content than S30V. Do you find the same in regards to polishing?Bodog wrote: PSF27 is noticeably harder to reprofile compared to an S30v millie.

Is the edge thickness similar on both knives, are the bevel widths similar?

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

Bodog, do you find it (PSF27) harder to grind than 154CM, Elmax?

Is the Military similar to other S30 knives in grinding ease/difficulty?

Is the Military similar to other S30 knives in grinding ease/difficulty?

Re: A conversation with Gayle Bradley - PSF27

154cm and Elmax are easier than S30V and PSF27 with 154cm being the easiest out of that group by far.. As a referenceCliff Stamp wrote:Bodog, do you find it (PSF27) harder to grind than 154CM, Elmax?

Is the Military similar to other S30 knives in grinding ease/difficulty?

S110V was probably obviously the hardest (thick stock).

PSF27

Elmax (thick stock)

Ingot D2 is close to s30v in my experience, both with relatively thin blades.

Elmax (thin stock)

B75P was also pretty easy (thick stock)

14c28n was fairly close to 154cm iirc.

8CR13MOV was easier.

AUS6 was easier (thick stock)

420HC was easier

1095 was easiest, maybe on par with 420HC.

The Elmax blades I have both take a superior polish.

I know I'm leaving some out. I'm just throwing out a quick, easy to digest comparative list as far as grindability in the steels I've used.

I can only guess that the PSF27 I have is pretty hard. I don't have a hardness tester. The spine corners didn't dent much at all when I was beating the crap out of it to straighten the blade if that's any indication, subjective as that may be. I don't have a lot of experience beating on knives with hammers.

They who dance are thought mad by those who do not hear the music.

Re: A conversation with Gayle Bradley - PSF27

For reference. Three knives were taken fairly low, around 9 degrees +/- 1 degrees, with about a 15 degree +/- 1 relief bevel, the two spydercos and the damascus. The others are about 17 +/- 1 per side with no relief bevel. That's not an all inclusive collection of blades I've used and sharpened or anything, just a quick reference. I tried to get a picture of the bevels and at the same time get the light reflecting off of the spine dents where I was beating on the MT with a hammer. And that damascus blade was almost ridiculously thick at the shoulders. I wasn't that happy with the grind but it became sentimental the day I received it so I won't send it back for any kind of rework.

Last edited by Bodog on Thu Feb 05, 2015 7:05 pm, edited 1 time in total.

They who dance are thought mad by those who do not hear the music.

Re: A conversation with Gayle Bradley - PSF27

After I experienced - about 20 hrs worth total - very difficult time with belt grind & hand sharpen my ht D2. More puzzled when I can easily reprofiled 20cv, s90v, s110v with SiC 180grit stone but D2 skidded around and yield scratch pattern of much smaller abrasive. I pondered for a while and came up with... Let's see how effective brain to post does :)

Reasoning by examples/#s, also let's ignore complexity of carbide type & shape and other variables. Assume same steel matrix hardness and abrasive = perfect cubic mono diamond.

S30V & refined-ingot-D2 & PSF27 carbide volume(CV) is around ~10% (note: volume is different than mass ~4%)

S110V CV around ~20%

assign average carbide dia size as = average(top ~15 upper/large size percentile), based from various sources and theoretical(until proven with SEM), let's hand-wave these average #s.

refined-D2/PSF27 = 1um (plausible, easy to prove with optical or SEM)

S30V = 2um

S110V = 3um

Which translate/interpret in carbide/particle density unit as

D2 has 8x higher density than S30V (cubic)

D2 has 13.5x higher density than S110V (cubic divide by s110v 2x CV)

Note: Divide those #s above by 2 to get intercarbide spacing in 2Dimension(ICS), i.e. 4x, 6.75x respectively.

For 60+um abrasive - D2 ICS limits abrasive penetration (2D surface and 3D volume perpectives), whereas S30V & S110V are more porous so ploughing is deeper.

As abrasive size decrease -> average pressure per contact point increase due to smaller/sharper abrasive edge (ok keep simple by ignore abrasive density here). Once abrasive edge-size is a few times smaller than ICS. says, around 600grit, ploughing depth penetration for these steels will be about the same. This continue until abrasive size less than 2-3x carbide size, whence the carbide protruding cutting edge/bit per pressure is less than 1/2 carbide diameter. Now, sharpening interaction switched from ploughing to mostly abrading mode, those steels (s110v, s30v) with larger/harder VC will be much harder to shape than smaller/softer CrC.

Density & penetration physics would still apply for other steels & variables to certain extend depend on context.

Reasoning by examples/#s, also let's ignore complexity of carbide type & shape and other variables. Assume same steel matrix hardness and abrasive = perfect cubic mono diamond.

S30V & refined-ingot-D2 & PSF27 carbide volume(CV) is around ~10% (note: volume is different than mass ~4%)

S110V CV around ~20%

assign average carbide dia size as = average(top ~15 upper/large size percentile), based from various sources and theoretical(until proven with SEM), let's hand-wave these average #s.

refined-D2/PSF27 = 1um (plausible, easy to prove with optical or SEM)

S30V = 2um

S110V = 3um

Which translate/interpret in carbide/particle density unit as

D2 has 8x higher density than S30V (cubic)

D2 has 13.5x higher density than S110V (cubic divide by s110v 2x CV)

Note: Divide those #s above by 2 to get intercarbide spacing in 2Dimension(ICS), i.e. 4x, 6.75x respectively.

For 60+um abrasive - D2 ICS limits abrasive penetration (2D surface and 3D volume perpectives), whereas S30V & S110V are more porous so ploughing is deeper.

As abrasive size decrease -> average pressure per contact point increase due to smaller/sharper abrasive edge (ok keep simple by ignore abrasive density here). Once abrasive edge-size is a few times smaller than ICS. says, around 600grit, ploughing depth penetration for these steels will be about the same. This continue until abrasive size less than 2-3x carbide size, whence the carbide protruding cutting edge/bit per pressure is less than 1/2 carbide diameter. Now, sharpening interaction switched from ploughing to mostly abrading mode, those steels (s110v, s30v) with larger/harder VC will be much harder to shape than smaller/softer CrC.

Density & penetration physics would still apply for other steels & variables to certain extend depend on context.

Re: A conversation with Gayle Bradley - PSF27

I was wondering about whether the size, distribution, and density of the carbide volume would affect it. Sounds like work has already been done with it.bluntcut wrote:After I experienced - about 20 hrs worth total - very difficult time with belt grind & hand sharpen my ht D2. More puzzled when I can easily reprofiled 20cv, s90v, s110v with SiC 180grit stone but D2 skidded around and yield scratch pattern of much smaller abrasive. I pondered for a while and came up with... Let's see how effective brain to post does :)

Reasoning by examples/#s, also let's ignore complexity of carbide type & shape and other variables. Assume same steel matrix hardness and abrasive = perfect cubic mono diamond.

S30V & refined-ingot-D2 & PSF27 carbide volume(CV) is around ~10% (note: volume is different than mass ~4%)

S110V CV around ~20%

assign average carbide dia size as = average(top ~15 upper/large size percentile), based from various sources and theoretical(until proven with SEM), let's hand-wave these average #s.

refined-D2/PSF27 = 1um (plausible, easy to prove with optical or SEM)

S30V = 2um

S110V = 3um

Which translate/interpret in carbide/particle density unit as

D2 has 8x higher density than S30V (cubic)

D2 has 13.5x higher density than S110V (cubic divide by s110v 2x CV)

Note: Divide those #s above by 2 to get intercarbide spacing in 2Dimension(ICS), i.e. 4x, 6.75x respectively.

For 60+um abrasive - D2 ICS limits abrasive penetration (2D surface and 3D volume perpectives), whereas S30V & S110V are more porous so ploughing is deeper.

As abrasive size decrease -> average pressure per contact point increase due to smaller/sharper abrasive edge (ok keep simple by ignore abrasive density here). Once abrasive edge-size is a few times smaller than ICS. says, around 600grit, ploughing depth penetration for these steels will be about the same. This continue until abrasive size less than 2-3x carbide size, whence the carbide protruding cutting edge/bit per pressure is less than 1/2 carbide diameter. Now, sharpening interaction switched from ploughing to mostly abrading mode, those steels (s110v, s30v) with larger/harder VC will be much harder to shape than smaller/softer CrC.

Density & penetration physics would still apply for other steels & variables to certain extend depend on context.

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: A conversation with Gayle Bradley - PSF27

Bluntcut,

There is data on HIP steels, showing the carbide distribution in them vs the traditional ingot steels, RWL-34/PM 15 vs ATS-34 :

vs

The HIP/PM process cut the carbide large aggregates in half.

The same type of comparison can be done in spray form, vs HIP, vs ingot, I posted a link on T15 in the above. Spray form is between HIP vs ingot, this spray form D2 would be between ingot and HIP D2, and ingot D2 is even more coarse than ingot ATS-34 so the primary aggregates would be expected to be > 10 microns.

Spray form D2 would thus be expected to have carbide aggregates much larger than S30V not less.

--

As an aside the primary carbide volume can be effected by the austenization time/temperature and mechanical deforming, hence in friction forging not only the austenite grain size, but the carbide volume are much reduced and the hardness is increased dramatically, ~5 HRC points. Curiously enough I did a passaround of a FF D2 blade and a Dozier D2 and everyone in the trial remarked they ground very similar, no significant difference in that (or any other respect).

In times like that though we have to realize that the difference in an absolute scale and then what is reflected in a practical one can be very different.

There is data on HIP steels, showing the carbide distribution in them vs the traditional ingot steels, RWL-34/PM 15 vs ATS-34 :

vs

The HIP/PM process cut the carbide large aggregates in half.

The same type of comparison can be done in spray form, vs HIP, vs ingot, I posted a link on T15 in the above. Spray form is between HIP vs ingot, this spray form D2 would be between ingot and HIP D2, and ingot D2 is even more coarse than ingot ATS-34 so the primary aggregates would be expected to be > 10 microns.

Spray form D2 would thus be expected to have carbide aggregates much larger than S30V not less.

--

As an aside the primary carbide volume can be effected by the austenization time/temperature and mechanical deforming, hence in friction forging not only the austenite grain size, but the carbide volume are much reduced and the hardness is increased dramatically, ~5 HRC points. Curiously enough I did a passaround of a FF D2 blade and a Dozier D2 and everyone in the trial remarked they ground very similar, no significant difference in that (or any other respect).

In times like that though we have to realize that the difference in an absolute scale and then what is reflected in a practical one can be very different.