- Heat treatment effects on CPM-M4 tool steel performance as edged blade material : https://ir.library.oregonstate.edu/xmlu ... 1957/54906" target="_blank

There are some interesting results and they directly answer some questions asked here on M4. For example it is known that M4 was too brittle in the BladeSports competitions until they adjusted the standard hardening. However you could ask is it better to adjust the temper or the soak? In general, very general it is better to adjust the soak - but that doesn't mean it works for everything. Well this paper addresses that as it looks at both adjustments and confirms that the soak adjustment produces the greater toughness.

There is also a very interesting point as it is one of the few materials papers which not only talks about knives but actually uses an ISO standard developed for knives - CATRA and presents data on M4 under varying HT protocols. What is very interesting is to look at the range of results or the precision/uncertainty. Remember now that this is a CATRA result, an edge retention trial by a machine on specific graded material. The results they got had a precision as low as 20%.

This means even a CATRA type test is +/- 20% and again that is a machine on graded stock. Now if you take away the graded stock and make that random, and you replace the machine by a person who varies speed, force, angle, and then you add in a very loose/subjective sharpness measurement then what do you think happens to that 20%. If it doesn't explode much higher - well then that data is likely manipulated by an external bias.

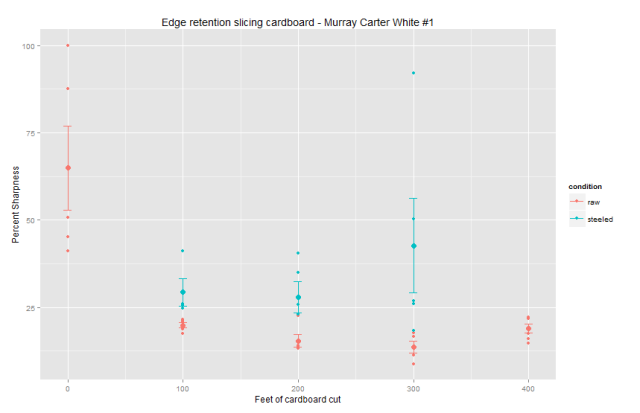

Here is some real hand sharpened data in comparison :

This isn't mine, it is a guy attempting to duplicate or at least parallel investigate some claims I made about steeling. This is real hand data with a careful sharpness measurement, just look at how much it scatters. However you can still draw some interesting conclusions, you just have to be very careful to not let your conclusions go beyond the ability of the data to support :

-edge retention is strongly non-linear

-white steel looks to respond well to steeling