I carry one of the rods and use it to sharpen a lot of utility knives, it isn't the ideal finish for it as it is really coarse however most of the blades are very dull, often damaged so it quickly gets it sharp. I have been asking for feedback and most of it has been really positive but again they are comparing the sharpened blade to a dull one so that doesn't really say much aside from very sharp blades (of any finish) cut better than dull ones.

I got a big bunch of the same cardboard boxes this weekend and decided to do a direct comparison in a simplified data collection/analysis. I have been refining my methods to speed them up but still get decent information :

-1/8" corrugated card stock, cut across the ridges in 30 cm slices

-sharpness tested by slicing bergia spinning thread under a 50 gram load

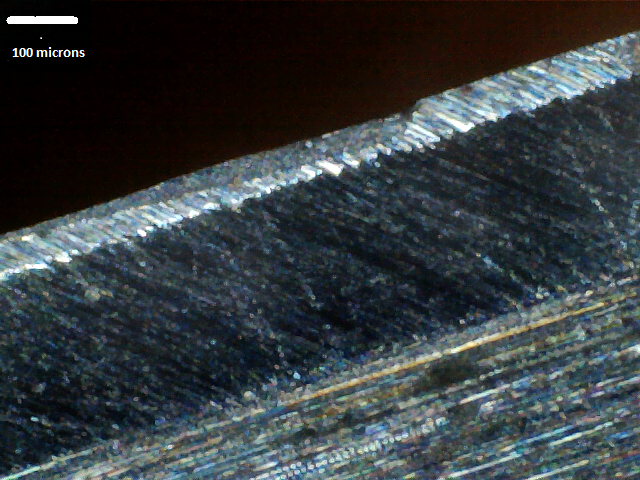

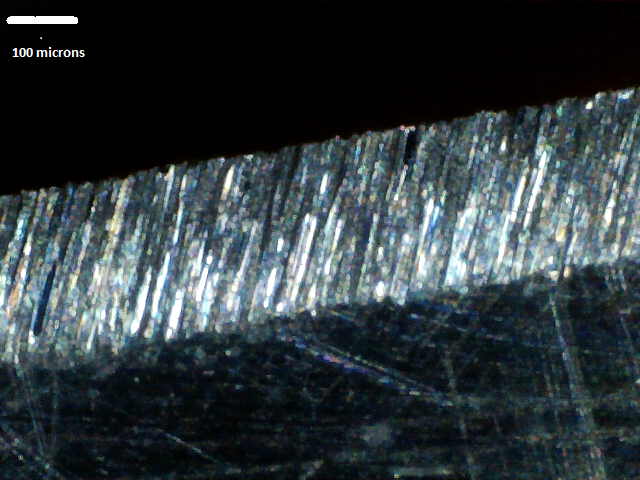

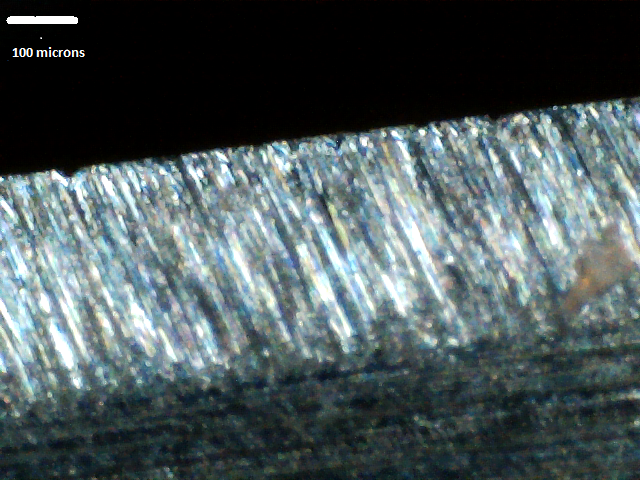

This was the blade :

It is a very common utility style blade, this is a folding model of the common Stanley. I compared :

-the as-boxed sharpness and edge retention

-the sharpness and edge retention off of the CBN rods at 15 dps

The sharpening was :

-10 pps, light force

-5 pps, very light force (5-10 grams)

-2 pps on the 20 dps side, just barely touching the stones

The CBN rods can easily produce a shaving edge using that method.

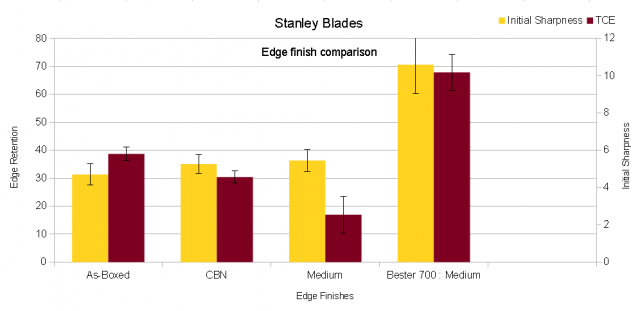

I did four runs, a quick check just to see what kind of difference was produced. The initial sharpness (lower number is higher sharpness, it is linear) :

As boxed : 23 (4)

CBN : 18 (2)

No significant difference, this was kind of interesting. I wasn't expecting to produce an edge which may in fact be sharper and is more consistent with the CBN rods.

In regards to edge retention I calculated the lifetime cutting efficiency which is basically the amount of material cut for amount of work you do cutting. The results (higher number is better edge retention) :

As boxed : 40 (3)

CBN : 30 (3)

The CBN edge retention while lower isn't significantly lower (the random spread in the results is large enough to prevent rejecting the null hypothesis that the edge retention is the same).

In short :

-the initial sharpness and edge retention are not significantly different

Now I only did four runs and cardboard is very variable in cutting - but still this is far more controlled than what anyone would see in actual use. This means that that initial sharpness and edge retention in use are likely to be seen as the same. This is kind of interesting when you consider the CBN rods very quickly reset the edge on these utility blades, even just 5-10 pps will get the edge back to cutting very well even when significantly damaged because the rods are so coarse.

After using these for awhile and sharpening many utility knives their usefulness outside the Sharpmaker is proving to be very high, so much so most people will ask "Hey, you got that file?" because of how simple it is to get an edge back shaving and cutting well.

--

Now to clarify something, I am comparing the edges in slicing which is the most favorable way for CBN, if I was push cutting plastics then the results would be expected to be different. I will likely do this later as well as maybe add a couple of more cardboard runs to see if I can see if they will be different if I refine the results a little.