Show your Mule

Re: Show your Mule

Hi Hoshko,

Welcome to our forum.

Hey Casper,

Great stuff. Thanx much for sharing.

sal

Welcome to our forum.

Hey Casper,

Great stuff. Thanx much for sharing.

sal

Re: Show your Mule

CasperFatone wrote: ↑Sat Apr 13, 2024 7:38 pmCocobolo scales that are fresh off the buffing wheel. No finish or buffing compound, just sanded to 1000 grit then buffed with a raw cotton fabric wheel. You can see why this wood is so desirable.

Casper, what kind of fasteners are those? They appear to be flat or domed the same on both sides?

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

- VeraX_Knives

- Member

- Posts: 71

- Joined: Mon Jun 06, 2022 2:36 pm

- Location: Bethel Park, Pennsylvania

Re: Show your Mule

I could argue that the pins are almost useless. Their diameter isn't exactly for strength it's for looks. Let's just walk through together how we make full tang knives in my shop or anywhere really. It's not a very efficient way of holding scales on or in place. It would need to be a mechanical bond and I'm assuming that all of you guys overdrill your holes slightly as I do in either metric or SAE, or let's say drill to EXACT sizes, it's still not going to work on the chemical bonding. I could see it making a difference if being dropped extremely hard or something like that but again, not technically the design. I'm a Chicago screw guy and I only use them on g10 not acrylics due to the.. obvious. I do prefer a mechanical bond but I have found in testing that the science is.. not exactly what I was taught in the real world (as should be expected by real scientists) and a good epoxy (not BJ's, people have their own preferences) can EXCEED my mechanical bond number expectations and any normal person's expectations. The steel usually fails first in my experience but I'm about as controlled environment as it gets, I don't want to say anything that could make someone think that I can't be wrong. I assure you I am often. Don't really gotta overcomplicate these full tang guys as I've learned - they don't do change or really like extremely boring to most people science stuff. I always prefer a mechanical and chemical bond FYI. I'm separating the two intentionally for these purposes based on entropy for the purposes of conversation and ease.

Screw heads? Look like CNCd to me almost or something like that? It's not a machine finish unless... intentional. Difficult to tell however I was busy looking at the wood grain lol

Edit: nvm they not fasteners they're pins that he's cut and sanded. Duh! (Please confirm my suspicions here or I'm going to seriously look like a moron

Jas

••• You say E = mc² × I argue E² = m²c⁴ + p²c² •••

Jason Ward • shockey01@gmail.com • +1 412-726-8610 • My Discord

Jason Ward • shockey01@gmail.com • +1 412-726-8610 • My Discord

-

CasperFatone

- Member

- Posts: 102

- Joined: Sat Nov 19, 2022 9:02 am

Re: Show your Mule

Those are just two pieces of 3/16” stainless rod that I was using in the shaping process. I put a slight bevel on the ends just to make inserting them a little easier. They fit pretty snug when both pins are in and won’t come out unless I push them out intentionally. I like to use them so I don’t have to keep screwing and unscrewing connectors, and I don’t need to worry about messing them up in any way.Bolster wrote: ↑Tue Apr 16, 2024 7:02 pmCasperFatone wrote: ↑Sat Apr 13, 2024 7:38 pmCocobolo scales that are fresh off the buffing wheel. No finish or buffing compound, just sanded to 1000 grit then buffed with a raw cotton fabric wheel. You can see why this wood is so desirable.

Casper, what kind of fasteners are those? They appear to be flat or domed the same on both sides?

I always do my final sanding/shaping/polishing with the scales pinned together like this. It’s nice because you avoid rounding over the scales where they meet the tang. It also makes it much harder to accidentally sand the edge to where it might end up no longer flush with the tang.

Amateur maker of folding knives and addicted to modding Spyderco knives

Folding Mules- m398 liner lock, Rex76 compression lock, 15v liner lock flipper

Folding Mules- m398 liner lock, Rex76 compression lock, 15v liner lock flipper

-

CasperFatone

- Member

- Posts: 102

- Joined: Sat Nov 19, 2022 9:02 am

Re: Show your Mule

You are 100% correct regarding the pins :)VeraX_Knives wrote: ↑Wed Apr 17, 2024 8:59 amI could argue that the pins are almost useless. Their diameter isn't exactly for strength it's for looks. Let's just walk through together how we make full tang knives in my shop or anywhere really. It's not a very efficient way of holding scales on or in place. It would need to be a mechanical bond and I'm assuming that all of you guys overdrill your holes slightly as I do in either metric or SAE, or let's say drill to EXACT sizes, it's still not going to work on the chemical bonding. I could see it making a difference if being dropped extremely hard or something like that but again, not technically the design. I'm a Chicago screw guy and I only use them on g10 not acrylics due to the.. obvious. I do prefer a mechanical bond but I have found in testing that the science is.. not exactly what I was taught in the real world (as should be expected by real scientists) and a good epoxy (not BJ's, people have their own preferences) can EXCEED my mechanical bond number expectations and any normal person's expectations. The steel usually fails first in my experience but I'm about as controlled environment as it gets, I don't want to say anything that could make someone think that I can't be wrong. I assure you I am often. Don't really gotta overcomplicate these full tang guys as I've learned - they don't do change or really like extremely boring to most people science stuff. I always prefer a mechanical and chemical bond FYI. I'm separating the two intentionally for these purposes based on entropy for the purposes of conversation and ease.

Screw heads? Look like CNCd to me almost or something like that? It's not a machine finish unless... intentional. Difficult to tell however I was busy looking at the wood grain lol

Edit: nvm they not fasteners they're pins that he's cut and sanded. Duh! (Please confirm my suspicions here or I'm going to seriously look like a moron)

Jas

Amateur maker of folding knives and addicted to modding Spyderco knives

Folding Mules- m398 liner lock, Rex76 compression lock, 15v liner lock flipper

Folding Mules- m398 liner lock, Rex76 compression lock, 15v liner lock flipper

Re: Show your Mule

Love the "tricks" being shared here.

sal

sal

- standy99

- Member

- Posts: 2217

- Joined: Sat Jul 22, 2017 11:07 am

- Location: Between Broome and Cairns somewhere

Re: Show your Mule

Have always used pins.

Pins of any size are actually a good thing as they negate all side to side or forward back movement of scales.This stops nearly all movement except up and down

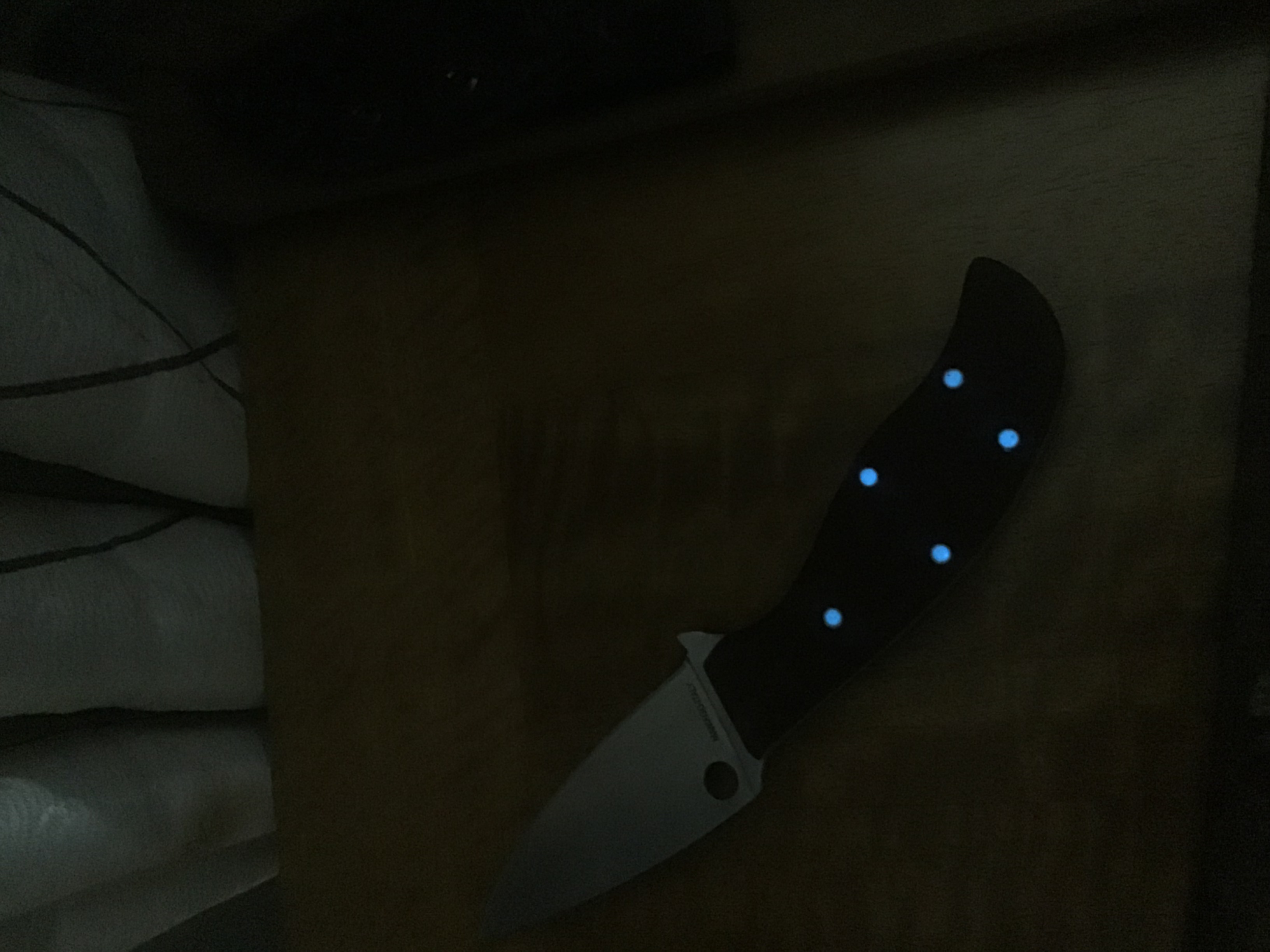

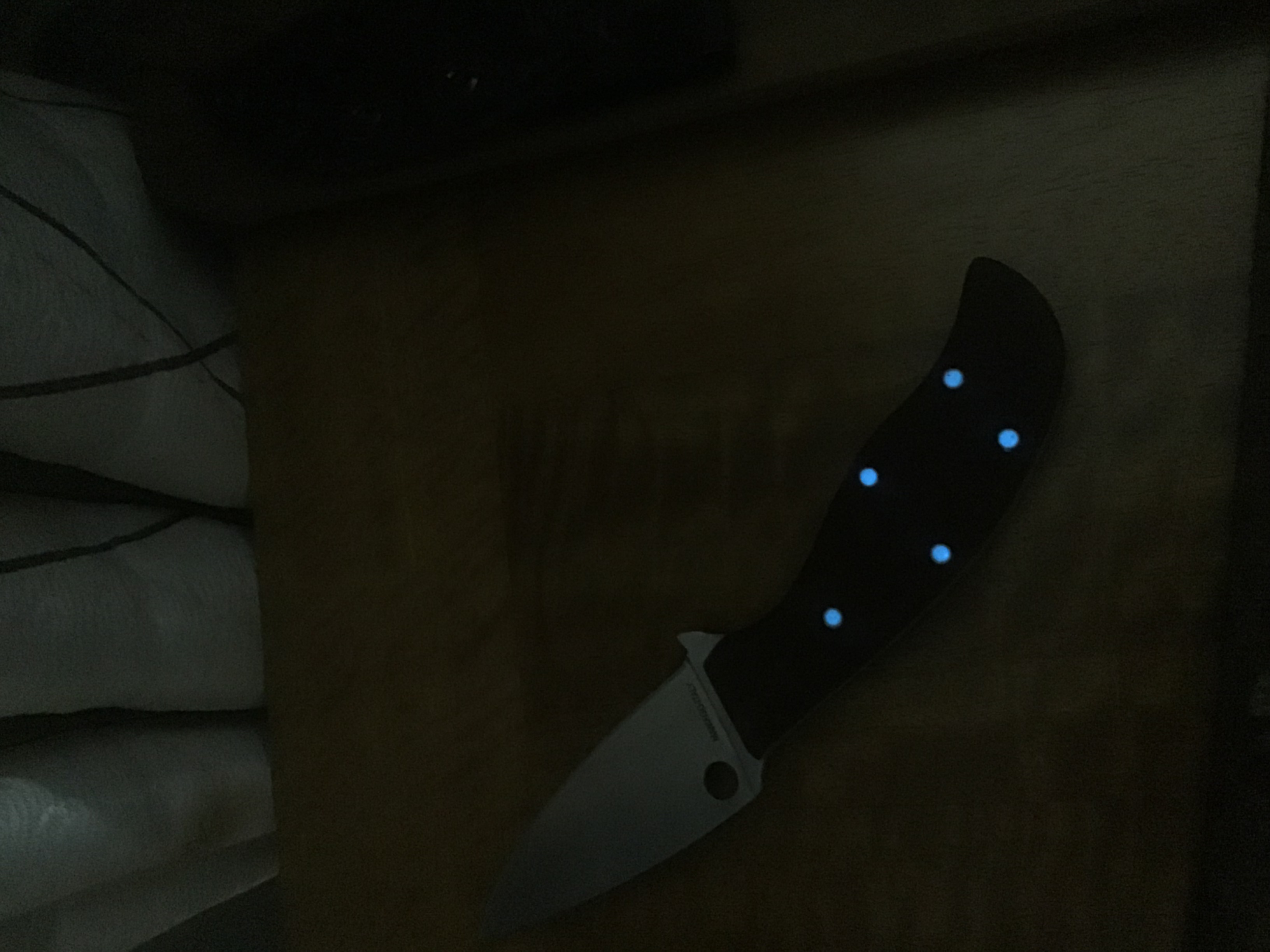

The epoxy is the mechanism of keeping the scales lateral and the amount of epoxy bridges a mule has is another benefit and why I don’t use Corby bolts. This gives the added advantage of being able to use G10 or glow-lume in aluminium like I have on my latest build.

Here are Ultem pins on a Ultem scale. (Which wouldn’t have looked as good with Colby or Chicago fasteners)

I use Corby bolts on a full tang knife without any drilled holes that do not offer an epoxy bridge.

Pins of any size are actually a good thing as they negate all side to side or forward back movement of scales.This stops nearly all movement except up and down

The epoxy is the mechanism of keeping the scales lateral and the amount of epoxy bridges a mule has is another benefit and why I don’t use Corby bolts. This gives the added advantage of being able to use G10 or glow-lume in aluminium like I have on my latest build.

Here are Ultem pins on a Ultem scale. (Which wouldn’t have looked as good with Colby or Chicago fasteners)

I use Corby bolts on a full tang knife without any drilled holes that do not offer an epoxy bridge.

Im a vegetarian as technically cows are made of grass and water.

- VeraX_Knives

- Member

- Posts: 71

- Joined: Mon Jun 06, 2022 2:36 pm

- Location: Bethel Park, Pennsylvania

Re: Show your Mule

I do that exact same thing that's how I recognized it just I usually use brass so it took a second lol. Glad I took the right guess finally!CasperFatone wrote: ↑Wed Apr 17, 2024 9:53 pmThose are just two pieces of 3/16” stainless rod that I was using in the shaping process. I put a slight bevel on the ends just to make inserting them a little easier. They fit pretty snug when both pins are in and won’t come out unless I push them out intentionally. I like to use them so I don’t have to keep screwing and unscrewing connectors, and I don’t need to worry about messing them up in any way.Bolster wrote: ↑Tue Apr 16, 2024 7:02 pmCasperFatone wrote: ↑Sat Apr 13, 2024 7:38 pmCocobolo scales that are fresh off the buffing wheel. No finish or buffing compound, just sanded to 1000 grit then buffed with a raw cotton fabric wheel. You can see why this wood is so desirable.

Casper, what kind of fasteners are those? They appear to be flat or domed the same on both sides?

I always do my final sanding/shaping/polishing with the scales pinned together like this. It’s nice because you avoid rounding over the scales where they meet the tang. It also makes it much harder to accidentally sand the edge to where it might end up no longer flush with the tang.

K thanks for the glow-lume idea that I'm totally going to rip off of youstandy99 wrote: ↑Thu Apr 18, 2024 8:56 amHave always used pins.

Pins of any size are actually a good thing as they negate all side to side or forward back movement of scales.This stops nearly all movement except up and down

The epoxy is the mechanism of keeping the scales lateral and the amount of epoxy bridges a mule has is another benefit and why I don’t use Corby bolts. This gives the added advantage of being able to use G10 or glow-lume in aluminium like I have on my latest build.

Here are Ultem pins on a Ultem scale. (Which wouldn’t have looked as good with Colby or Chicago fasteners)

I use Corby bolts on a full tang knife without any drilled holes that do not offer an epoxy bridge.

When I was talking about pins, I meant not just with the mules but anyone here who makes knives. I think they can be overrated depending on what type of epoxy people are using for the knives they make, and as your bottom pic seems to show, You do it the same as me it seems without pins. I just don't pin the material unless it's one that I need to. If anyone here has ever taken a sledge hammer to g10, you can screw that as tight as you want. It won't crack.

-Jason

••• You say E = mc² × I argue E² = m²c⁴ + p²c² •••

Jason Ward • shockey01@gmail.com • +1 412-726-8610 • My Discord

Jason Ward • shockey01@gmail.com • +1 412-726-8610 • My Discord

- standy99

- Member

- Posts: 2217

- Joined: Sat Jul 22, 2017 11:07 am

- Location: Between Broome and Cairns somewhere

Re: Show your Mule

No drama happy to helpVeraX_Knives wrote: ↑Thu Apr 18, 2024 9:45 am

K thanks for the glow-lume idea that I'm totally going to rip off of you. I cannot believe that I didn't know about this stuff when I use SrAl2O4 strontium aluminate glow in the dark coatings on my kitchen handles as an option. Seriously thank you lol. A lot.

-Jason

No it has Ultem pins if you look closely, made from Ultem rods that I purchased with the sheet.VeraX_Knives wrote: ↑Thu Apr 18, 2024 9:45 am

You do it the same as me it seems without pins.

-Jason

Im a vegetarian as technically cows are made of grass and water.

- VeraX_Knives

- Member

- Posts: 71

- Joined: Mon Jun 06, 2022 2:36 pm

- Location: Bethel Park, Pennsylvania

Re: Show your Mule

Ah, so it's a polymer rod basically like you can use acrylic? Ohhhh it's polyetherimide. Okay now we're on the same page I'm sorry my man I should probably have used the internet to figure out what material we were talking about before posting. Sorry guys for brand name confusion.standy99 wrote: ↑Thu Apr 18, 2024 9:52 amNo drama happy to helpVeraX_Knives wrote: ↑Thu Apr 18, 2024 9:45 am

K thanks for the glow-lume idea that I'm totally going to rip off of you. I cannot believe that I didn't know about this stuff when I use SrAl2O4 strontium aluminate glow in the dark coatings on my kitchen handles as an option. Seriously thank you lol. A lot.

-Jason

No it has Ultem pins if you look closely, made from Ultem rods that I purchased with the sheet.VeraX_Knives wrote: ↑Thu Apr 18, 2024 9:45 am

You do it the same as me it seems without pins.

-Jason

Jay

••• You say E = mc² × I argue E² = m²c⁴ + p²c² •••

Jason Ward • shockey01@gmail.com • +1 412-726-8610 • My Discord

Jason Ward • shockey01@gmail.com • +1 412-726-8610 • My Discord

-

ykspydiefan

- Member

- Posts: 500

- Joined: Wed May 27, 2020 9:28 pm

Re: Show your Mule

Hey Standy99!

Love all your GITD work.

Thanks for sharing

Love all your GITD work.

Thanks for sharing

Spyderco: Tenacious G10, Waterway, Para 3 Spy27, Pacific Salt H1, Catcherman, In the Mule Team Stable(Z-Max, Z-Wear, S45VN, Magnacut, SRS13/SUS405, M398, Aeb-l, 15v)

Re: Show your Mule

Apparently I missed out again on the HIC mule recently reopened for sale. If anyone has one they do not want, I would like to buy it. Thanks!

-

Steeltoez83

- Member

- Posts: 472

- Joined: Sat Aug 01, 2020 8:51 am

Re: Show your Mule

I guess i missed out on the HIC mule re drop too.

"Nothing is built on stone; all is built on sand, but we must build as if the sand were stone."

Re: Show your Mule

The re-drop hasn't happened yet. The factory is very busy with regular production. Please be patient.

sal

sal

-

Steeltoez83

- Member

- Posts: 472

- Joined: Sat Aug 01, 2020 8:51 am

Re: Show your Mule

Well that's good news. My apologies for the misunderstanding Sal.

"Nothing is built on stone; all is built on sand, but we must build as if the sand were stone."

- FullScaler

- Member

- Posts: 266

- Joined: Sat Nov 30, 2019 12:42 am

- Contact:

Re: Show your Mule

Finally got my green honeycomb scales finished. Now I just need to figure out a nice color sheath to go with them

Re: Show your Mule

Hey Full Scaler,

That's really a "Looker". Beautiful.

sal

That's really a "Looker". Beautiful.

sal

Re: Show your Mule

Agreed. Phenomenal!

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

-

CasperFatone

- Member

- Posts: 102

- Joined: Sat Nov 19, 2022 9:02 am

Re: Show your Mule

Fresh set of Lignum Vitae scales that I made. This is widely thought of as the most dense wood in existence and has a natural waxy/oily feel to it that is very unique. It is actually pretty easy to work with but the dust tends to clog sandpaper a little more than normal

Amateur maker of folding knives and addicted to modding Spyderco knives

Folding Mules- m398 liner lock, Rex76 compression lock, 15v liner lock flipper

Folding Mules- m398 liner lock, Rex76 compression lock, 15v liner lock flipper

- VeraX_Knives

- Member

- Posts: 71

- Joined: Mon Jun 06, 2022 2:36 pm

- Location: Bethel Park, Pennsylvania

Re: Show your Mule

CasperFatone wrote: ↑Tue Apr 23, 2024 10:52 pmFresh set of Lignum Vitae scales that I made. This is widely thought of as the most dense wood in existence and has a natural waxy/oily feel to it that is very unique. It is actually pretty easy to work with but the dust tends to clog sandpaper a little more than normal

Looks good not going to lie I've in passing heard of that lignum vertae whatever and to me it's.. it's in the name lol like it's lignin and density isn't everything in wood. As far as I know, (yes please teach me something here) it's the composite type layering of the core of a tree correct? So in effect it's water content and.. growth patterns over.. the polymers that exist correct?

That give wood it's mechanical properties*.

••• You say E = mc² × I argue E² = m²c⁴ + p²c² •••

Jason Ward • shockey01@gmail.com • +1 412-726-8610 • My Discord

Jason Ward • shockey01@gmail.com • +1 412-726-8610 • My Discord