Well how did you sharpen exactly and reprofile in those cases? The more steps and details you can give of the tools you use and progression along the way, etc. would be helpful. Maybe it's something to do with how you were trying to accomplish this. The steel itself is something that would not be considered excessively brittle to expect chipping, though it's certainly not a tough steel as it's more of a medium carbide steel.

Native Chief Lightweight!!!

- Traditional.Sharpening

- Member

- Posts: 286

- Joined: Thu Mar 02, 2023 12:29 am

Re: Native Chief Lightweight!!!

Re: Native Chief Lightweight!!!

no issues with my bd1n zcuts chipping and they're run pretty thin. my se's are 15 degrees inclusive with thin stock.

Looking forward to these. been carrying an m4 chief in anticipation. got a feeling this and the millie 2 will be battling it out over the next year.

Looking forward to these. been carrying an m4 chief in anticipation. got a feeling this and the millie 2 will be battling it out over the next year.

Re: Native Chief Lightweight!!!

I am also looking forward to the LWT Chief. Folders with 4"-blades feel familiar to me, since Opinel 10 is one of my favourite folders. I also like my Native 5 LWT in Spy 27, so the Spy27 Chief seems like an obvious option.

Re: Native Chief Lightweight!!!

I didn’t even know my Z-cut was BD1N. No issues either but in the kitchen it hardly sees difficult material. I had assumed these were 8CrMoV13 just from how inexpensive they were.

Re: Native Chief Lightweight!!!

14 DPS 1st reprofiling and 17 DPS second reprofiling after a couple of sharpening before and after the 14 DPS reprofiling.Traditional.Sharpening wrote: ↑Sat Oct 07, 2023 3:55 pmWell how did you sharpen exactly and reprofile in those cases? The more steps and details you can give of the tools you use and progression along the way, etc. would be helpful. Maybe it's something to do with how you were trying to accomplish this. The steel itself is something that would not be considered excessively brittle to expect chipping, though it's certainly not a tough steel as it's more of a medium carbide steel.

Chipping occured while whittling "medium" hardness wood and pretty demanding cutting tasks. It was an angle issue at first, then on 17 it was better but still not as good as I would want. I can do these tasks at 17 dps on the SPY27 Manix

Robin. Finally made an IG : ramo_knives

MNOSD member 004* aka Mr. N5s

- Traditional.Sharpening

- Member

- Posts: 286

- Joined: Thu Mar 02, 2023 12:29 am

Re: Native Chief Lightweight!!!

This is still not enough information to rule out the way you are grinding as a potential contributor. How was the knife reprofiled. What type of stone/grit are you forming an apex off of?Ramonade wrote: ↑Sun Oct 08, 2023 4:00 am14 DPS 1st reprofiling and 17 DPS second reprofiling after a couple of sharpening before and after the 14 DPS reprofiling.Traditional.Sharpening wrote: ↑Sat Oct 07, 2023 3:55 pmWell how did you sharpen exactly and reprofile in those cases? The more steps and details you can give of the tools you use and progression along the way, etc. would be helpful. Maybe it's something to do with how you were trying to accomplish this. The steel itself is something that would not be considered excessively brittle to expect chipping, though it's certainly not a tough steel as it's more of a medium carbide steel.

Chipping occured while whittling "medium" hardness wood and pretty demanding cutting tasks. It was an angle issue at first, then on 17 it was better but still not as good as I would want. I can do these tasks at 17 dps on the SPY27 Manix

Re: Native Chief Lightweight!!!

Everytime I relate an experience you're putting my sharpening skills in question. For the first 2 or 3 times I took the time and explained how I sharpen and we ended up clearly seeing that it wasn't my sharpening that was the issue.Traditional.Sharpening wrote: ↑Sun Oct 08, 2023 7:41 amThis is still not enough information to rule out the way you are grinding as a potential contributor. How was the knife reprofiled. What type of stone/grit are you forming an apex off of?Ramonade wrote: ↑Sun Oct 08, 2023 4:00 am14 DPS 1st reprofiling and 17 DPS second reprofiling after a couple of sharpening before and after the 14 DPS reprofiling.Traditional.Sharpening wrote: ↑Sat Oct 07, 2023 3:55 pmWell how did you sharpen exactly and reprofile in those cases? The more steps and details you can give of the tools you use and progression along the way, etc. would be helpful. Maybe it's something to do with how you were trying to accomplish this. The steel itself is something that would not be considered excessively brittle to expect chipping, though it's certainly not a tough steel as it's more of a medium carbide steel.

Chipping occured while whittling "medium" hardness wood and pretty demanding cutting tasks. It was an angle issue at first, then on 17 it was better but still not as good as I would want. I can do these tasks at 17 dps on the SPY27 Manix

CTS-BD1N is on the lower end of toughness and isn't supported by much strength, that's all.

We're more in the realm of user error than sharpening mistake here. Wrong steel and wrong geometry for the task.

Robin. Finally made an IG : ramo_knives

MNOSD member 004* aka Mr. N5s

Re: Native Chief Lightweight!!!

Dude is always way too technical. There's very few that care about sharpening as deeply as he does. Almost takes the fun out of it.

15  's in 10 different steels

's in 10 different steels

1 - Bradford Guardian 3 / Vanadis 4E Wharnie

1 - Monterey Bay Knives Slayback Flipper / ZDP 189

1 - CRK Small Sebenza 31/Macassar Ebony Inlays

1 - CRK Large Inkosi Insingo/ Black Micarta Inlays

1 - CRK Small Sebenza 31 Insingo/Magnacut

-Rick

1 - Bradford Guardian 3 / Vanadis 4E Wharnie

1 - Monterey Bay Knives Slayback Flipper / ZDP 189

1 - CRK Small Sebenza 31/Macassar Ebony Inlays

1 - CRK Large Inkosi Insingo/ Black Micarta Inlays

1 - CRK Small Sebenza 31 Insingo/Magnacut

-Rick

Re: Native Chief Lightweight!!!

Mine has a quarter of its teeth chipped, so ymmv. I'm not saying it's a bad steel btw, it's just that I did not have excellent experiences with what I've used the steel for. I mostly compared it to SPY27 which can do what BD1N do and with which I did not have the same "issues".vivi wrote: ↑Sat Oct 07, 2023 4:44 pmno issues with my bd1n zcuts chipping and they're run pretty thin. my se's are 15 degrees inclusive with thin stock.

Looking forward to these. been carrying an m4 chief in anticipation. got a feeling this and the millie 2 will be battling it out over the next year.

I might get another BD1N knife and beat on it then, just in case I dismissed a good low carbide steel.

Robin. Finally made an IG : ramo_knives

MNOSD member 004* aka Mr. N5s

-

Steeltoez83

- Member

- Posts: 484

- Joined: Sat Aug 01, 2020 8:51 am

Re: Native Chief Lightweight!!!

After reading this I'm curious to test my bd1n polestar for toughness now. I've always liked diamond stones for bd1n to shape the nitrides. I notice a difference in edge longevity whenever I do that.

"Nothing is built on stone; all is built on sand, but we must build as if the sand were stone."

- Traditional.Sharpening

- Member

- Posts: 286

- Joined: Thu Mar 02, 2023 12:29 am

Re: Native Chief Lightweight!!!

So was this the basic progression above and reprofiling used on the BD1N? Are you taking the edge all the way to apex on the F80 or is it not completely apexed until later grits? Can you try to put some measure of force on what you consider 'minimal pressure'? This is not as difficult as it sounds, if you simply take a bathroom/kitchen scale and press down with the same degree of force to gain a rough estimate. Can you estimate the force on both the stone grinding and stropping?Ramonade wrote: ↑Sun Oct 08, 2023 8:45 amI know how to sharpen, I know this is not a comment to denigrate my skills or anything, but I won't talk about damage if it is due to me not being able to reach an apex or reduce then get rid of the burr ^^. I use venev Cerberus Dog and venev Pegasus stones. I have a WS Precision Adjust that I modded for stability (no movement of the clamp anymore) and being able to use the Cerberus Dog stones on. I reprofile with this and sharpen freehand (until I someday might have to reprofile).

I don't really get what you mean by "how you grind the edge" ? If I'm sharpening I simply hit the whole bevel on every pass. I check every few passes, or sometimes even each pass, to see what I'm doing.

Low pressure since the start, reducing burr before getting to the next stone. I can usually cleanly cut toilet paper after my first stone. This 4V wasn't an exception (well, with an F80 edge it's not as clean of a cut, butit helps me attest that my apex is good).

Usual progression is F80 / F150 / F240. I went farther with this 4V to see how it would behave (F400). Then after the final stone I go to my strops which are hard leather with good backing, minimal pressure is used for a couple of passes on the 3 microns, then 1 micron then 0.25 micron Gunny Juice.

After the first reprofiling/sharpening I did cut cardboard, wood and other stuff to see after each cut if an imperceptible burr did not stay (it rarely does).

I have a jeweler's loupe and other gear to use if I ever have trouble on a particular blade.

Re: Native Chief Lightweight!!!

I apex and reduce burr on every stone, before going to the next... And I let the stone do the work, not my arm  I sharpen knives daily, in any steel from simple carbon to Maxamet. Some people don't know anything about anything and will cry they have an issue with their knife without even apexing while sharpening. That's not me, now I won't go in anymore detail because It feels like justifying myself to someone I don't even know.

I sharpen knives daily, in any steel from simple carbon to Maxamet. Some people don't know anything about anything and will cry they have an issue with their knife without even apexing while sharpening. That's not me, now I won't go in anymore detail because It feels like justifying myself to someone I don't even know.

And no ! I won't bring the scale out ! I refuse !

I refuse !

And no ! I won't bring the scale out !

Robin. Finally made an IG : ramo_knives

MNOSD member 004* aka Mr. N5s

Re: Native Chief Lightweight!!!

I only use diamonds so can't tell much. I'd be interested to see what kinds of resulsts you get from a real situation toughness test !Steeltoez83 wrote: ↑Sun Oct 08, 2023 9:07 amAfter reading this I'm curious to test my bd1n polestar for toughness now. I've always liked diamond stones for bd1n to shape the nitrides. I notice a difference in edge longevity whenever I do that.

In "regular cutting tasks", where there wasn't ever any sort of lateral forces during the cut, it's been pretty good. The edge retention isn't crazy, but from what I've experienced it was respectable for that class of steel

Too bad they cost 150+ € now

Robin. Finally made an IG : ramo_knives

MNOSD member 004* aka Mr. N5s

-

Steeltoez83

- Member

- Posts: 484

- Joined: Sat Aug 01, 2020 8:51 am

Re: Native Chief Lightweight!!!

I measure toughness thru chopping on an ice block. And the steels ability to absorb the blows while still able to pass my edge standards for testing. Since blade geometry has zero influence on my testing style, I get to evaluate the steel accurately. I've read quite a few experiences that differ from my own results on certain steels. My xhp Para 3 rockwelled at 63 so I don't like testing it bcuz it gives higher numbers. And my bd1 manix was 58 hrc which is alot lower than when I tested newer bd1 for hrc. There's always a possibility you might have a softer bd1n manix. But it sounds like you already took steps to get the most out of that knife. Your a great sharpener so I know it's not a technique issue. In Larrins toughness chart he lists vtoku at medium toughness so I'm gonna run it against my stretch. I only have a Para 3 in spy27 and the polestar and Para 3 are not in the same size category I use for testing.Ramonade wrote: ↑Sun Oct 08, 2023 1:24 pmI only use diamonds so can't tell much. I'd be interested to see what kinds of resulsts you get from a real situation toughness test !Steeltoez83 wrote: ↑Sun Oct 08, 2023 9:07 amAfter reading this I'm curious to test my bd1n polestar for toughness now. I've always liked diamond stones for bd1n to shape the nitrides. I notice a difference in edge longevity whenever I do that.

In "regular cutting tasks", where there wasn't ever any sort of lateral forces during the cut, it's been pretty good. The edge retention isn't crazy, but from what I've experienced it was respectable for that class of steel. It just chipped a bit on the kind of cuts where you might torque the blade a bit, a thing that SPY27 seemed to handle better. I might try to get a Polestar and compare, even if buying a BD1N Manix again would be the best choice to compare with the SPY27.

Too bad they cost 150+ € now

"Nothing is built on stone; all is built on sand, but we must build as if the sand were stone."

- Traditional.Sharpening

- Member

- Posts: 286

- Joined: Thu Mar 02, 2023 12:29 am

Re: Native Chief Lightweight!!!

It's not necessary to use a scale in this case but can help to truly understand what your idea of pressure is, as this is subjective in all cases. The fact that you are apexing directly off such coarse stones is most likely a factor here, especially as the edge angle becomes lower as this causes the apex itself to finish more coarse for any given stone/grit.Ramonade wrote: ↑Sun Oct 08, 2023 1:20 pmI apex and reduce burr on every stone, before going to the next... And I let the stone do the work, not my armI sharpen knives daily, in any steel from simple carbon to Maxamet. Some people don't know anything about anything and will cry they have an issue with their knife without even apexing while sharpening. That's not me, now I won't go in anymore detail because It feels like justifying myself to someone I don't even know.

And no ! I won't bring the scale out !I refuse !

I consider it to be a less than ideal approach that you are using, while it can certainly get the edge sharp, I would by no means consider your sharpening approach optimal, in the sense that I believe it is causing problems with durability. Getting the edge sharp is only part of the way to getting an optimal edge. You have to be able to do it without introducing weakened/fatigued/strained/etc. metal at the apex which will lead to premature failure through fracture, etc.

Your approach may work just fine for simpler steels but I believe it causes these sorts of issues for 'problematic' steels in that I mean that some steels just really let you know about issues there. This is not only my observation but it was also written about by Cliff Stamp as well in his observation. When he was working with simpler steels he found that he could use something like a coarse 220 grit waterstone (JIS/ANSI) to shape the edge and go straight to a finishing stone to set the apex.

What he noticed as the steels became higher alloyed was that he often needed something like this :

very coarse roughly 200 grit stone to remove damage or change angles

1000-2000 or higher grit muddy waterstone to remove all damage to the apex caused by the coarse stone (King 1000, Bester 700, Sigma Power Select 1000, etc. -- were the ones he used)

hard bonded stone/plate for setting the apex. (Spyderco Ceramic or DMT/Atoma/CBN plates, etc)

If you're not open to trying a different approach to rule out what you are doing as a factor then how could you possibly know what you are doing is not to blame here? It's much easier to just blame the steel than to be open to the idea that something you may be doing is a contributing factor. If there is an issue with the steel then I would want to make sure that what I was doing to sharpen was not being mistaken for a steel issue. I tend to believe true steel issues from Spyderco are rare!

I suspect that if you'd learn how to sharpen a different way -- without relying on generating a burr, by using a muddy waterstone to prepare the apex for a micro bevel and remove all damage from coarse stones, you would likely see your problem disappear entirely. This method is proven on problematic steels for setting the edge prior to apexing and Cliff had written about this extensively and experimented with numerous methods prior to arriving at this.

The progression you mention seems to me to be not serving any real purpose, in that those are all coarse stones. Those types of stones/grit ratings are what I would consider to be 'fixer' stones in that they are generally used for repairs/mods. I do not see much value in working through those grits when you could simply switch to a medium grit muddy waterstone from the F80 to remove all traces of damage to the apex prior to apexing. This is damage you will not find with your loupe, btw.

We don't always know as much as we think we know and this is the only way to actually learn something... to admit that we may not have it all figured out. I don't doubt you can get knives sharp and burr free, I just think your process is setting you up for these sorts of problems in the long run even if they may only present as an obvious issue at times.

To be clear, anytime you form a burr you are creating microscopic damage that is not easy to detect, which has traveled beyond the burr itself back into the knife. You can remove the burr but you still have not removed the damage at/behind the apex. If you doubt this then you can easily prove it by bending any type of thin metal wire back and forth until it breaks. You'll see that the flexing took place far beyond just the point where the metal finally fractures away.

The only way to get the apex very thin without generating a heavy burr is to use a muddy medium grit stone equivalent as it grinds the burr away as quickly as it begins to form and being a higher grit in the first place there is less damage accompanying it in the first place as the depth of damage is directly tied to the size of the abrasive cutting the steel. In some cases you may even need to go up to 2000 grit JIS+ on really problematic steels to form a clean/damage free apex.

See below for a reference to this type of approach, taken from : viewtopic.php?f=2&t=63505

Cliff Stamp wrote: ↑Mon Apr 07, 2014 9:05 pmIf you are working with very high carbide steels, especially the extreme ones and HSS, then the Sigma Power Series stones are waterstones made for that, so if you are looking at waterstones they would seem to be the obvious choice.

However, unless you are working on Japanese style knives where you have a wide bevel and you are actually bringing on the final polish on that bevel itself there is no need and no real benefit to getting a massive stone grit range.

With proper use of relief and micro-bevels you need at most three stones and even that is to handle extreme conditions in steels :

-an exceptionally coarse stone to remove lots of metal, angle changes, visible chips

-a medium stone which does the bulk of sharpening

-a finishing stone

Decent choices are :

-cheap garden store hones

People ignore these, but you can buy them locally for ~$5 and they work extremely fast because they are very low grit as in the grit rating is in the double digits. I do not recommend you apex an edge with them unless you are experienced in handling stones as you can damage an edge but with a little practice you can stop right as the edge starts to apex and then move to the medium stones.

But it is possible to do this with that stone :

A higher end version of this are the general 200 grit stones, I like the Sigma Power Select II stone in that range which doesn't cut as fast, but wears slower and is easier to control. But is also more than 10X the cost.

Medium stones :

-Bester 700 for ATS34/S30V class steels

-SPS-II 1000 for the higher carbide ones

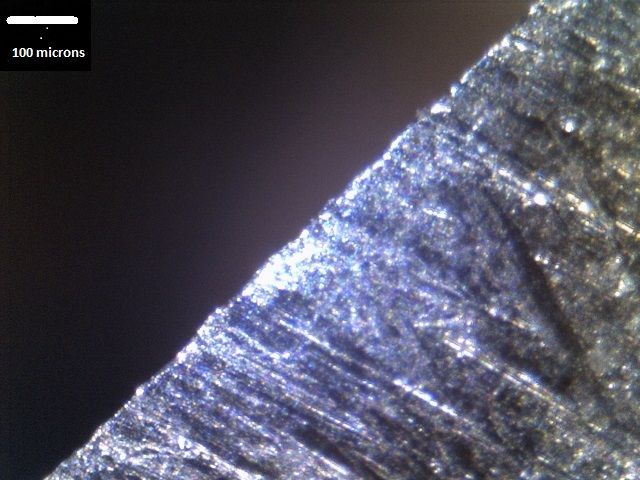

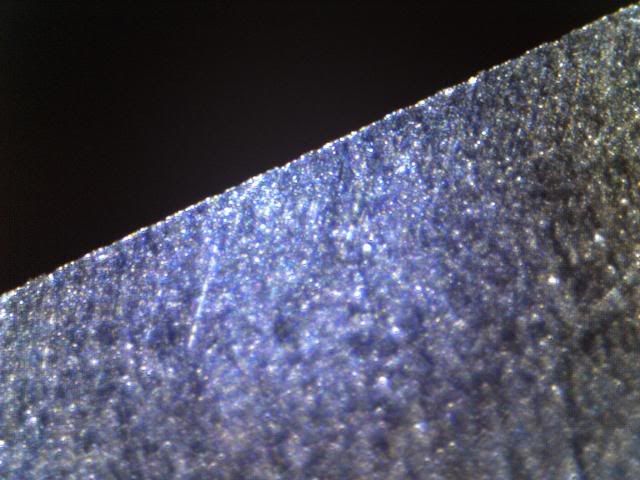

These stones can leave a very fine edge, under 50X magnification the edge can be a straight line :

Aside from the first sharpening, or when a knife is really damaged, this is likely going to be your most used stone.

For finishing :

-Spyderco Ceramics

-DMT/Atoma Plates

are very nice for setting the final micro-bevel and are much easier to do with than waterstones. However the knife has to be properly apexed off of the medium stone, it should :

-be shaving

-slicing newsprint readily

-hint at being able to do a true-push cut

the final bevel is then set with very few passes which are very light and that just sets the edge at the exact grit you want for the cutting ability. The medium stone mainly just gets right of the rough shaping stone gouges and for general work brings it to a working apex.

The main thing to keep in mind is that tools are a far and distant second to technique. If you can't do this : https://youtu.be/mSt2mCWGFII then better stones won't help much. If you can, they make it a lot easier.

-

Steeltoez83

- Member

- Posts: 484

- Joined: Sat Aug 01, 2020 8:51 am

Re: Native Chief Lightweight!!!

My toughness testing verified the results Dr Larrin had. In his knife steel nerds articles he listed vtoku at 5.5 for toughness. And bd1n at around 3.5. He also listed some other steels at that same toughness level as bd1n. However the bd1n dulled quicker in testing than vtoku.

"Nothing is built on stone; all is built on sand, but we must build as if the sand were stone."

Re: Native Chief Lightweight!!!

What is the deal with page 3 of this thread. Thought this was a Native Chief LW thread.

Steel novice who self-identifies as a steel expert. Proud M.N.O.S.D. member 0003. Spydie Steels: 4V, 15V, 20CV, AEB-L, AUS6, Cru-Wear, HAP40, K294, K390, M4, Magnacut, S110V, S30V, S35VN, S45VN, SPY27, SRS13, T15, VG10, XHP, ZWear, ZDP189

Re: Native Chief Lightweight!!!

Since Traditional.Sharpening has harassing you about your sharpening technique covered, I will zero in on what exactly you are doing with a Z-cut that knocked some teeth out?

- Traditional.Sharpening

- Member

- Posts: 286

- Joined: Thu Mar 02, 2023 12:29 am

Re: Native Chief Lightweight!!!

I'm failing to see how toughness is even a factor in this BD1N issue. Toughness measures resistance to fracturing on impact and Ramonade seems to have done nothing along the lines of impact work from what he has outlined using the knife for when he noted the chipping. Also curious how you can say definitively that Ramonade is a great sharpener and most certainly not a technique issue.Steeltoez83 wrote: ↑Sun Oct 08, 2023 1:57 pmI measure toughness thru chopping on an ice block. And the steels ability to absorb the blows while still able to pass my edge standards for testing. Since blade geometry has zero influence on my testing style, I get to evaluate the steel accurately. I've read quite a few experiences that differ from my own results on certain steels. My xhp Para 3 rockwelled at 63 so I don't like testing it bcuz it gives higher numbers. And my bd1 manix was 58 hrc which is alot lower than when I tested newer bd1 for hrc. There's always a possibility you might have a softer bd1n manix. But it sounds like you already took steps to get the most out of that knife. Your a great sharpener so I know it's not a technique issue. In Larrins toughness chart he lists vtoku at medium toughness so I'm gonna run it against my stretch. I only have a Para 3 in spy27 and the polestar and Para 3 are not in the same size category I use for testing.Ramonade wrote: ↑Sun Oct 08, 2023 1:24 pmI only use diamonds so can't tell much. I'd be interested to see what kinds of resulsts you get from a real situation toughness test !Steeltoez83 wrote: ↑Sun Oct 08, 2023 9:07 amAfter reading this I'm curious to test my bd1n polestar for toughness now. I've always liked diamond stones for bd1n to shape the nitrides. I notice a difference in edge longevity whenever I do that.

In "regular cutting tasks", where there wasn't ever any sort of lateral forces during the cut, it's been pretty good. The edge retention isn't crazy, but from what I've experienced it was respectable for that class of steel. It just chipped a bit on the kind of cuts where you might torque the blade a bit, a thing that SPY27 seemed to handle better. I might try to get a Polestar and compare, even if buying a BD1N Manix again would be the best choice to compare with the SPY27.

Too bad they cost 150+ € now

- cabfrank

- Member

- Posts: 2897

- Joined: Sun May 08, 2011 9:07 pm

- Location: Northern California, USA, Earth

Re: Native Chief Lightweight!!!

My goodness.