But the problem is that such marketing information rarely tells you what they are measuring exactly, how the steels were hardened and what kind of precision they had so interpreting the results is problematic. If you do get some more data often you find that they are doing something like comparing adhesive wear resistance which can show very large differences in HSS vs Cr based steels but there is little correlation between that and abrasive wear which tends to happen in knife use.

The steel itself is an interesting blend of elements as it is a high carbon/tungsten modification to 3V (not that 3V came first, just looking at the difference) which an addition of Silicon. Silicon in small elements is in all steels (it is a deoxidizer) but in large amounts it is added for toughness (it is in the shock steels for example) because among other things it retard the formation of cementite at grain boundaries which happens in tempering (the carbon comes out of the martensite, forms epsilon carbide and then that dissolves and forms cementite). These cementite formations allow brittle failure hence suppressing them allows the tempering of the steel (makes it tougher) without causing the embrittlement of the cementite formation. Due to the higher carbon and tungsten it would be expected to have better abrasive wear than 3V and better hardness, and since this is mainly MC type carbides (small) and the silicon addition, it would be expected to have similar toughness.

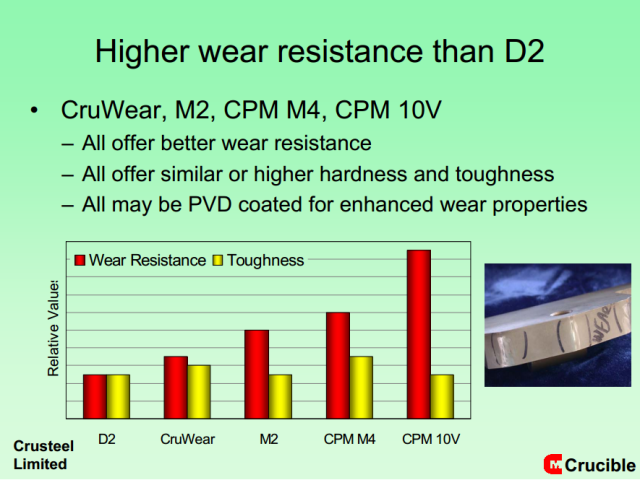

But that still leaves the question as to how does it compare to a normal/workhorse steel like D2?

Well I have been looking for that for awhile, the problem is the massive amount of different tradenames doesn't make it easy, but you can save searches now and have results notified which is a help. Here is one such study :

"MACHINING SCIENCE AND TECHNOLOGY Vol. 8, No. 2, pp. 193–210, 2004, Kinematics and Wear of Tool, Blades for Scrap Tire Shredding"

It is an interesting work as it compares 4340 and D2 for such work and then CruWear to D2 extensively. It also mentions 3V and HSS and sort of implies possible future experiments. It also looks at chipping and chipping + wear. Interestingly enough there is no significant difference in chipping, but Cruwear is about 2:1 in terms of an improvement to resist wear. However there is not a lot of detail on how the steels were hardened, and it looks like both had significant retained austenite as the D2 blade was 56 HRC unworn and 59 HRC worn, compared to 58 and 61 for the CruWear. The results might not be as different with varying heat treatments of D2 which can achieve 62 HRC with full martensite.

It is an interesting steel and I am likely to pick up a Spyderco in it at some point. I have 3V, but the problem is that it is normally used in larger blades where I don't like how it performs at all as the grindability is far too low. I would be really interested if anyone has a CruWear from Spyderco and has a decent D2 blade (Dozier for example) and can see a significant difference in wear resistance, or other properties.