There is strong interest in ceramics because of the extreme properties they have (temperature resistance, wear resistance, stiffness, strength, etc.). The main problem they have is just brittleness compared to steels. Anyone who has used one of the older ceramic blades has seen how they can be broken under impacts which are trivial compared to steels.JD Spydo wrote:Or do any of you know about current studies or advances in Sintered materials.

However, and this is a big however, modern reinforcement of ceramics is literally exploding the paradigm of toughness. One of the main ways this is gained is through transformation toughening. This is similar to work hardening in steels. When the ceramic comes under a load and starts to crack this crack actually causes change in the ceramic which inhhibit crack growth (r-curve behavior).

A few papers :

-r-curve utilization : http://www2.lbl.gov/ritchie/Library/PDF ... ramics.pdf" target="_blank

-review of high toughness ceramic for cutting tools : http://www.journalamme.org/papers_vol54_2/5427.pdf" target="_blank

-commercial data sheet : http://www.360ip-japan.com/uploads/docs ... ummary.pdf" target="_blank

The last one is similar to a data sheet from Bohler or similar, it isn't a peer reviewed source so look at it as basically a claim. However it does show the potential for extreme toughness in ceramics, just look at how high the toughness is claimed compared to standard high-toughness ceramics.

As more of a source of entertainment, a reality show which runs a traditional knifemaker vs a engineering team which eventually uses a carbide blade (this is a sintered product) :

https://youtu.be/UyCuR16HUBc" target="_blank

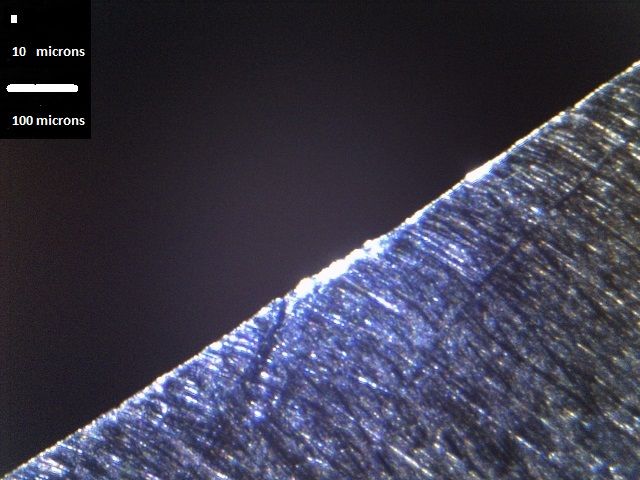

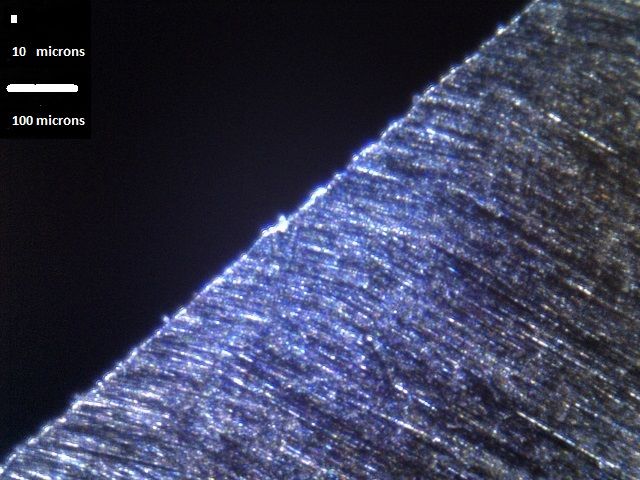

The big problem to over come using these as traditional knife steels is mainly sharpening. They do not sharpen well on most stones, you need CBN or diamond to work them and burr-sharpening doesn't work. However if you are not reliant on burr methods and you micro-bevel they are not that problematic to work. The only thing I have not been able to figure out is how to get an aggressive low-grit slicing edge on them, they seem to tend to be abraded mainly by fracture (steel will deform) and thus they really only get really sharp under high polishes.