All grits or just the fine ones?jackknifeh wrote: One thing about the Shapton glass stones and is probably true of other water stones is once the edge is pretty sharp, if I raise the angle too high and use enough pressure I can cut into the stone.

ZDP-189 - choosing the right waterstone

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

Which ones do you have? Are they any different from the Shapton Glass?bluntcut wrote:

Shapton Pro stones most are hard in compare to other waterstone. Except 120grit is soft, way too soft.

Re: ZDP-189 - choosing the right waterstone

I believe the "ceramic" word is being used by Shapton to describe the abrasive, the "ceramic" particles are suspended in some kind of binder, it's not a solid material like Spyderco stones. Mine doesn't seem to make a muddy slurry at all either, so I'm curious as to what the real differences in binder are vs other water stones. I'm thinking of getting some higher grits to go with my 120.

Context: other water stones I own are the Edge pro apex stock waterstones, which make a fine slurry, and King 1000 and 6000 (I believe) that I bought from Murray Carter's site years ago when I first got interested in sharpening. The King waterstones get very muddy, particularly the 1000 if you use much force.

Context: other water stones I own are the Edge pro apex stock waterstones, which make a fine slurry, and King 1000 and 6000 (I believe) that I bought from Murray Carter's site years ago when I first got interested in sharpening. The King waterstones get very muddy, particularly the 1000 if you use much force.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

Just as a point of clarification, all modern abrasives are ceramics, aluminum oxide / alumina is a ceramic as is silicon carbide (carbide is a type of ceramic like steel is a type of metal).

Norton uses the label ceramic to describe a grade of alumina formed by a particular process (seeded gel) which creates alumina which fractures on a very small scale (micron) which are the ceramic belts like the Blaze.

It tends to cause some confusion because again they are all ceramics, in fact the binder for Norton stones can also be called a ceramic as well (vitrified bond).

Norton uses the label ceramic to describe a grade of alumina formed by a particular process (seeded gel) which creates alumina which fractures on a very small scale (micron) which are the ceramic belts like the Blaze.

It tends to cause some confusion because again they are all ceramics, in fact the binder for Norton stones can also be called a ceramic as well (vitrified bond).

Re: ZDP-189 - choosing the right waterstone

I really wish there was like an ASTM standard for binder hardness in waterstones to help understand differences beyond just grits (even those seem to vary substantially). Compared to other hobbies I have (practical shooting, computer gaming, car modification, etc.) and my professional life(manufacturer's rep in the commercial construction industry) the knife sharpening world seems very subjective and vague.

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: ZDP-189 - choosing the right waterstone

Probably all of them. But to actually cut into the stone you really need to be trying to do it. Meaning having the angle way too high with a lot of pressure.Cliff Stamp wrote:All grits or just the fine ones?jackknifeh wrote: One thing about the Shapton glass stones and is probably true of other water stones is once the edge is pretty sharp, if I raise the angle too high and use enough pressure I can cut into the stone.

Jack

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

There are actually fairly strict grading for abrasives, you just only see them used in industrial wheels. For example :

- http://www.keihin-kogyo.co.jp/en/produc ... ousei.html" onclick="window.open(this.href);return false;

The problem is that with stones we don't have any of this information. It is like buying a knife and just being told it is "steel" .

- http://www.keihin-kogyo.co.jp/en/produc ... ousei.html" onclick="window.open(this.href);return false;

The problem is that with stones we don't have any of this information. It is like buying a knife and just being told it is "steel" .

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

Do you notice it any more/less with other waterstones?jackknifeh wrote:

Probably all of them. But to actually cut into the stone you really need to be trying to do it. Meaning having the angle way too high with a lot of pressure.

Re: ZDP-189 - choosing the right waterstone

I own combination of 8 Glass & Pro stones - from 120 to 16K. Pro is a thicker stone with softer binder and lower abrasive density than Glass. These grits are chunk of hard ceramic particles, while Alumina & others are crystal aggregate. Shapton has tight meshed particle size tolerance (from scratch pattern under optical microscope) - i.e. no odd deep mystery scratches. It's essential for me to polish steel coupons before light etch for nanograph.

Note: shapton white glass is harder&denser than high-carbon glass stone.

Note: shapton white glass is harder&denser than high-carbon glass stone.

Edit: I don't use 120 & 220 much. I prefer cheap + large coarse AlO or SiC stones for uber high pressure and corner filing - work well enough w/o having to worry to ruin fairly pricey stones.Cliff Stamp wrote:Which ones do you have? Are they any different from the Shapton Glass?bluntcut wrote:

Shapton Pro stones most are hard in compare to other waterstone. Except 120grit is soft, way too soft.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

I don't know what distinction you are trying to make here. Alumina is just the common name for aluminum oxide, it is a ceramic, it has a crystal structure (as do all ceramics). Yes it can be made by fusing smaller crystals (seeded gel is this type) but it isn't always made that way as there are many ways to make alumina. It is used in both resin and vitrified bonded abrasives (and even metal bonded ones - Chosera).bluntcut wrote: These grits are chunk of hard ceramic particles, while Alumina & others are crystal aggregate.

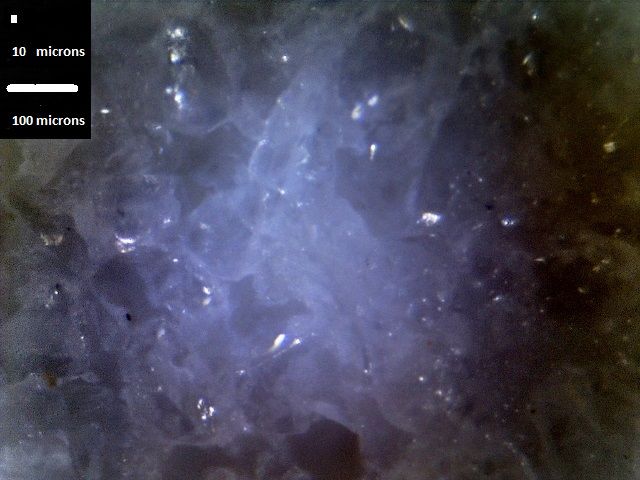

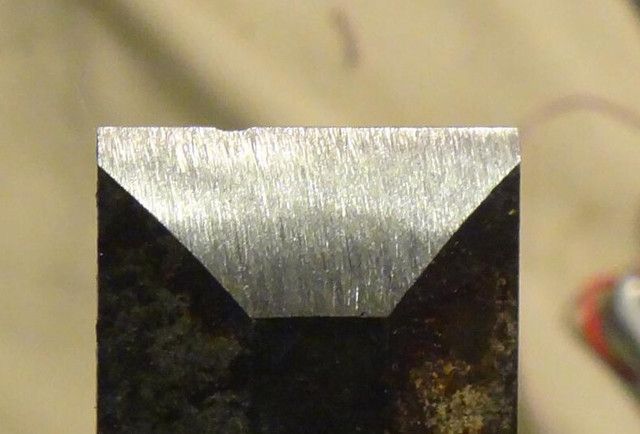

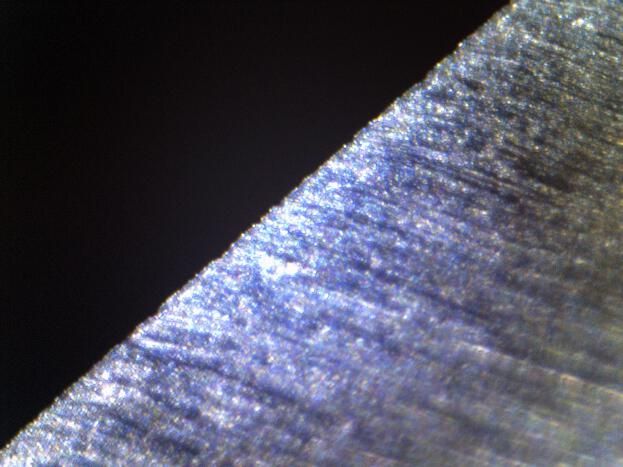

Here is a Shapton 120 :

It is a very weak bond, nice stone for low pressure grinding, too weak for much else as the pressure readily exceeds the bond strength and it just sheds unworn grit. I have higher grit ones I have not used them yet. In regards to grit variability, I have not seen much difference in stones aside from diamond. Even the very basic stones tend to produce very consistent scratch patterns. A stone with a weak bond which generates a slurry will in general grind "softer" and produce a finer scratch pattern simply because the abrasive is cushioned by the slurry which also blends any scratches due to perpendicular grinding.

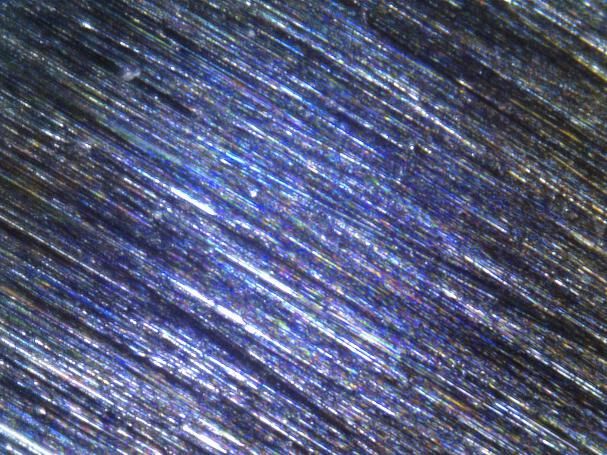

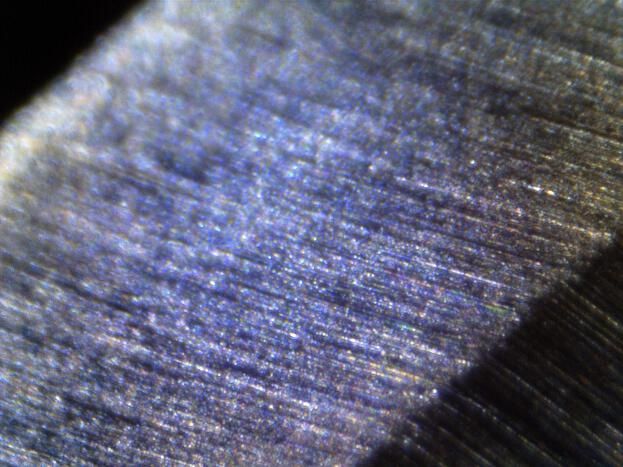

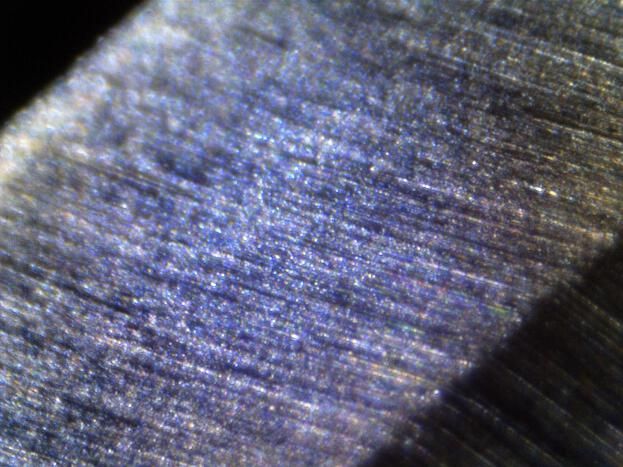

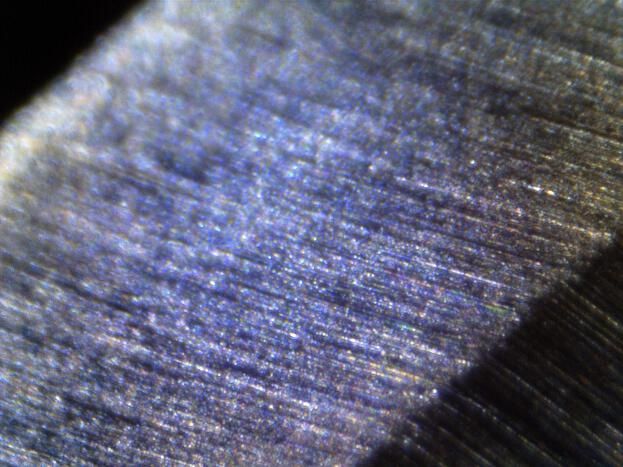

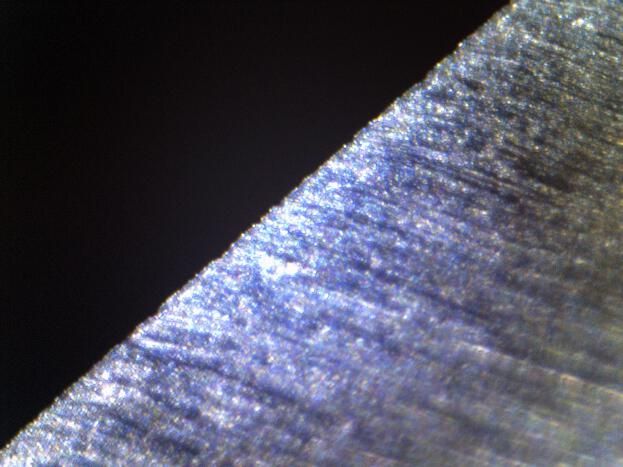

This is a really strong bond stone (light slurry) :

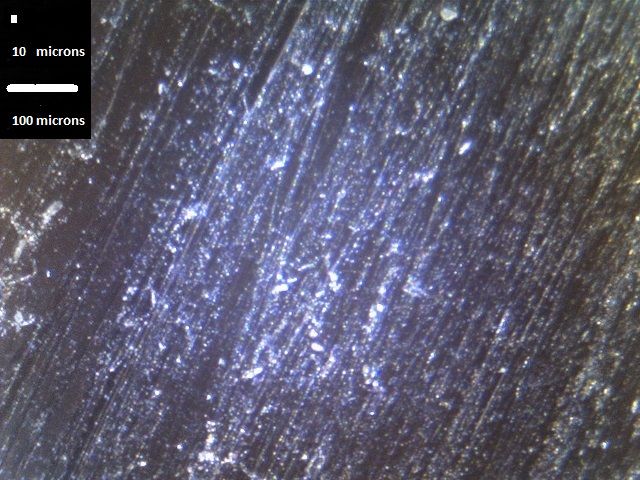

This is a really week bond (heavy slurry) :

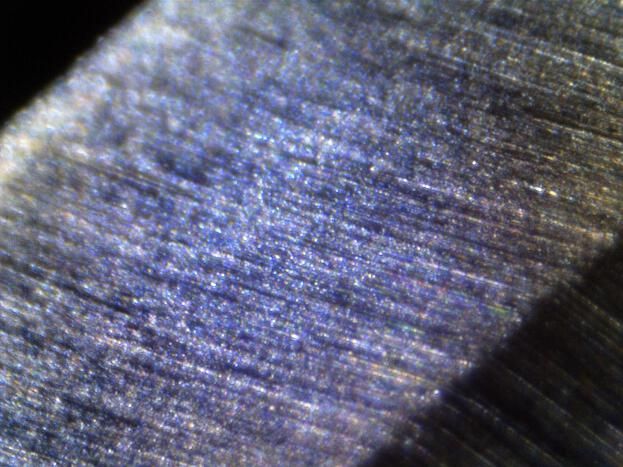

The difference in them is really obvious under magnification but they also produce very different finishes with the naked eye. The weak stone (Suehiro 'Chemical') produces a hazy finish, the strong stone (Suehiro Ryu) produces a much more harsh/uniform finish. A lot of people attribute this to some kind of grading uniformity but it isn't that, it is just the effect of the slurry and how it produces 3-body effects. If you let a slurry build up on a strong stone it will start to do the same thing and eventually it turns into this :

This is almost all 3-body, no parallel scratches any more. This however is the same grit of stone, it just has a fully slurry and so produces a very fine finish.

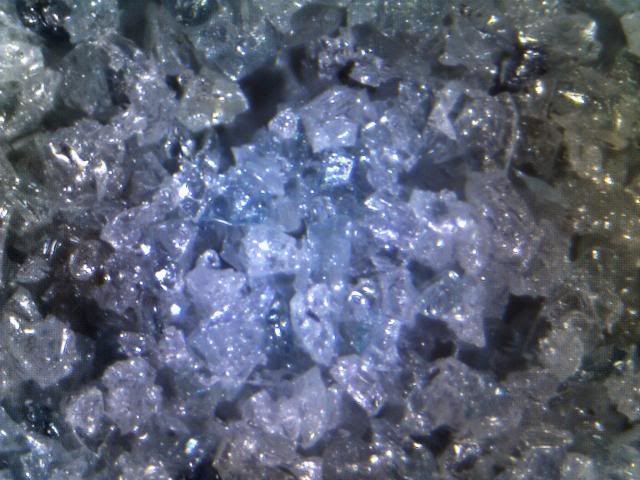

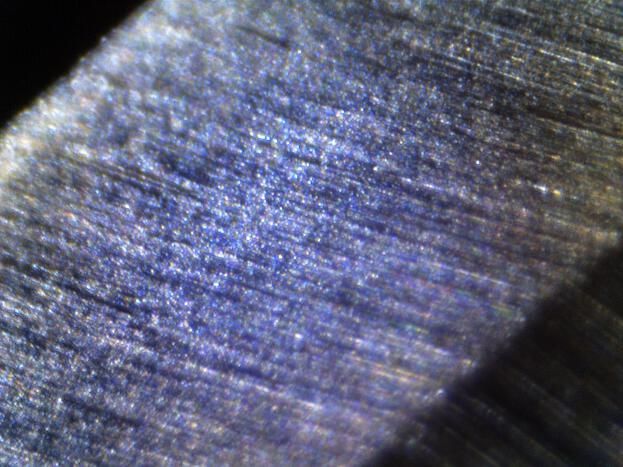

Stones with really weak bonds and ideally have some kind of filler binder produces that finish readily. That is why those stones are often praised for polishing as they naturally do that, you have to work at it with the stronger bonded stones. That is a Naniwa Superstone 400. That kind of finish is harder to get with the SPS-II stones as they don't have any binder (or almost none) they are just silicon carbide :

Note how you can just see grit, no real binder. That is a SPS-II 240, it is the harshest grinding stone I own, it tends to really resist producing a blended scratch pattern.

Re: ZDP-189 - choosing the right waterstone

For fast manual metal removal, I grind against ceramic belt staple to a 2x4. I guess, there are quite a bit of binder on those belt too.

Try a glass stone. It could be a useful (or just a pricey 5mm rip-off) sharpening tool in your bag.

Try a glass stone. It could be a useful (or just a pricey 5mm rip-off) sharpening tool in your bag.

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: ZDP-189 - choosing the right waterstone

I've never tried cutting into any other water stones. I only did it the one time because someone else got a set and mentioned it on another forum.

I got about half my Shapton glass stones on ebay from a Japanese guy in Japan. He had them for WAY less money than anywhere else I found. He doesn't sell them anymore I don't think. But he also had a brown colored Shapton glass stones. I think they were supposed to be softer. Here is a link to the stones on his store. The ones he used to sell are greyed out, not available. When he started running out of grits I asked why and he said something about them being discontinued. I emailed CKTG about it and they said they weren't being discontinued. Anyway, does anyone know about the brown Shapton glass stones or used them? Might take a gander at the Shapton site.

He has other Japanese type stones or knives. Worth a look I think. I think he has folding knives that are forged by a bladesmith. Don't know anything about the quality. Oh yeah, the price for saving a lot of money is it took 4-5 weeks to get an order. But I remember saving $35 on my 16k.

http://www.ebay.com/itm/JAPANESE-Shapto ... 747413aea8" onclick="window.open(this.href);return false;

Jack

PS

Just looked at the ebay store and found this statement.

"S" mark attached grit number means softer bonding agent. Check below chart.

I got about half my Shapton glass stones on ebay from a Japanese guy in Japan. He had them for WAY less money than anywhere else I found. He doesn't sell them anymore I don't think. But he also had a brown colored Shapton glass stones. I think they were supposed to be softer. Here is a link to the stones on his store. The ones he used to sell are greyed out, not available. When he started running out of grits I asked why and he said something about them being discontinued. I emailed CKTG about it and they said they weren't being discontinued. Anyway, does anyone know about the brown Shapton glass stones or used them? Might take a gander at the Shapton site.

He has other Japanese type stones or knives. Worth a look I think. I think he has folding knives that are forged by a bladesmith. Don't know anything about the quality. Oh yeah, the price for saving a lot of money is it took 4-5 weeks to get an order. But I remember saving $35 on my 16k.

http://www.ebay.com/itm/JAPANESE-Shapto ... 747413aea8" onclick="window.open(this.href);return false;

Jack

PS

Just looked at the ebay store and found this statement.

"S" mark attached grit number means softer bonding agent. Check below chart.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

I have done the same, interesting for experiment, this is 36 grit :bluntcut wrote:For fast manual metal removal, I grind against ceramic belt staple to a 2x4.

It can't even resolve at 50X magnification, the grits won't even fit on screen, at 5X magnification :

However I don't tend to use it much because even the Norton coarse grit bench stone (120 grit) is fast enough to rip a full bevel down on a chisel.

The Sigma Power 120 is a decent coarse grit stone, weaker bond than the Norton India/Crystolon, but much stronger than the Shapton Pro 120. The Sigma Power is too weak for chisels, nice for knives though. I have a whack ton of stones :

I am still trying to figure out a way to actually rank/compare them quantitatively. It isn't as trivial as I thought because of the interplay between pressure, fluid and the steel ground. The Suehiro Ryu for example doesn't grind the same slurry wise on L6 at 57 HRC as it does at 10V at 64 HRC. It takes a lot more pressure to form a slurry with the 10V. I think I know how to scale it, I just need to do the measurements. I think it should scale similar to (hardness of abrasive-hardness of steel)/hardness of steel .

I have at some point plan to pick them up.Try a glass stone. It could be a useful (or just a pricey 5mm rip-off) sharpening tool in your bag.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

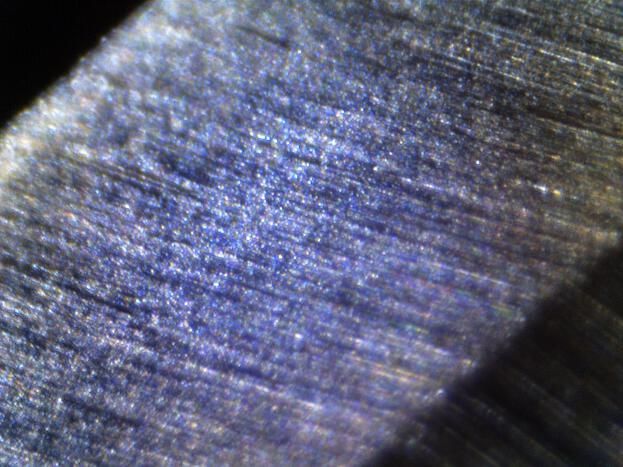

Here is a little playing around with a thick slurry on a fairly strong stone which naturally doesn't make a heavy slurry (Suehiro Ryu #300) :

Note how only the bottom of the bevel is in focus and I can slowly walk that focus up the bevel :

+

and the final apex :

The heavy slurry causes a very light convexing of the edge bevel. This is on a Pingo/N690Co.

Note how only the bottom of the bevel is in focus and I can slowly walk that focus up the bevel :

+

and the final apex :

The heavy slurry causes a very light convexing of the edge bevel. This is on a Pingo/N690Co.

-

can't freehand

- Member

- Posts: 160

- Joined: Thu Jan 01, 2015 4:19 pm

Re: ZDP-189 - choosing the right waterstone

I recently bought an actual waterstone, my first, a King 6000 grit, $19 off Amazon.

I have no trouble sharpening my ZDP-189 Endura on ceramic rods, diamond or oil stones. However, my first try with the King 6000 was a total failure. I used extremely light pressure and I could only ever get it to barely shave hair. I'm really not sure what is going on. Perhaps I am supposed to use it differently from the other abrasives I've listed?

Normally I'd read around on Google to try and figure out my newbie problem but my current Fall schedule is too heavy for anything besides brief cries for help.

I have no trouble sharpening my ZDP-189 Endura on ceramic rods, diamond or oil stones. However, my first try with the King 6000 was a total failure. I used extremely light pressure and I could only ever get it to barely shave hair. I'm really not sure what is going on. Perhaps I am supposed to use it differently from the other abrasives I've listed?

Normally I'd read around on Google to try and figure out my newbie problem but my current Fall schedule is too heavy for anything besides brief cries for help.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

Setting an apex with slurry forming stone can be frustrating if you are using to working with solid ceramics or diamond plates. When you put water on the stone and the stone breaks down and forms a mixture then that mix of water and abrasive keeps smashing into the apex as you are sharpening and it can blunt the knife as fast as it sharpens it.

There are a few ways to get around this :

-don't use such stones to set the apex, only work the edge

-as you get close to the desired sharpness flush the stone and keep flushing it, don't build up a thick slurry

-use edge trailing passes

There are a few ways to get around this :

-don't use such stones to set the apex, only work the edge

-as you get close to the desired sharpness flush the stone and keep flushing it, don't build up a thick slurry

-use edge trailing passes

-

can't freehand

- Member

- Posts: 160

- Joined: Thu Jan 01, 2015 4:19 pm

Re: ZDP-189 - choosing the right waterstone

That's what it was then, the slurry. I making passes with a lot of water on the surface on the stone, after having already soaked it, so my slurry was probably massive. It was a great learning experience.

I'm going to do the flush you recommend and also perhaps use as little post-soak water as possible when passing? Maybe just using the leftover from the flush to replenish the stone's thirst. I assume that would give the dislodged abrasive less of a chance to collide with the apex.

I'm going to do the flush you recommend and also perhaps use as little post-soak water as possible when passing? Maybe just using the leftover from the flush to replenish the stone's thirst. I assume that would give the dislodged abrasive less of a chance to collide with the apex.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

When you are setting the apex with a micro-bevel it should take very very passes. If it takes so many passes that a slurry develops or the stone gets loaded then the edge isn't ready for the apex. Is it possible to sharpen that way, sure - but you are making life very difficult for yourself. It is like breaking the lugs on a tire after you jack up the car. You can certainly change a tire that way but most people would not recommend it.can't freehand wrote: I'm going to do the flush you recommend and also perhaps use as little post-soak water as possible when passing?

Re: ZDP-189 - choosing the right waterstone

Great pics Cliff. Thanx.

sal

sal

Re: ZDP-189 - choosing the right waterstone

This is a great thread. I think I need to pick up a Naniwa 400 Super Stone. The fact it gives burr free edges ready for a microbevel is huge to me for saving time and frustration. As for the glasstones, I have the 1000, 4000, 8000, and 16000 and find they cut fast and clean on all of the steels I've used on it (mostly the common high carbide steels seen in pocket knives (CPM M4 is my favorite among those), along with Super Blue and a few others on some kitchen knives. I usually flatten them after every 2-3 knives that I put a full bevel on (they usually do it quite fast assuming you don't take huge grit jumps), and it takes only maybe 15 seconds to clear off a pencil grid at that state of wear on a diamond plate for me. I could probably do better by waiting longer between flattenings, but I'm OCD about having a flat stone. It's probably irrational and wasteful, but I don't do enough sharpening to really take much off of the stones, they will last me years.

Cliff, if you are still watching this thread, what is the biggest grit jump you would do from the 400 SS when applying a microbevel? It sounds like the Spyderco fines aren't an issue, which makes me think the 8000 glasstones might be able to apply the microbevel without any problems. 8000 grit is pretty excessive for my EDC needs, I'm just curious. The DMT course I am using for the type of work you are doing with the 400 SS leaves a very toothy apex if you actually sharpen to the apex, and it needs to be refined by a several stones after that before I feel good about applying an 8000 grit microbevel. I usually go DMT course>DMT fine>glasstone 1000>glasstone 4000>glasstone 8000. A stone that could save me several steps of refinement before putting on a finer microbevel would be great for me.

Cliff, if you are still watching this thread, what is the biggest grit jump you would do from the 400 SS when applying a microbevel? It sounds like the Spyderco fines aren't an issue, which makes me think the 8000 glasstones might be able to apply the microbevel without any problems. 8000 grit is pretty excessive for my EDC needs, I'm just curious. The DMT course I am using for the type of work you are doing with the 400 SS leaves a very toothy apex if you actually sharpen to the apex, and it needs to be refined by a several stones after that before I feel good about applying an 8000 grit microbevel. I usually go DMT course>DMT fine>glasstone 1000>glasstone 4000>glasstone 8000. A stone that could save me several steps of refinement before putting on a finer microbevel would be great for me.