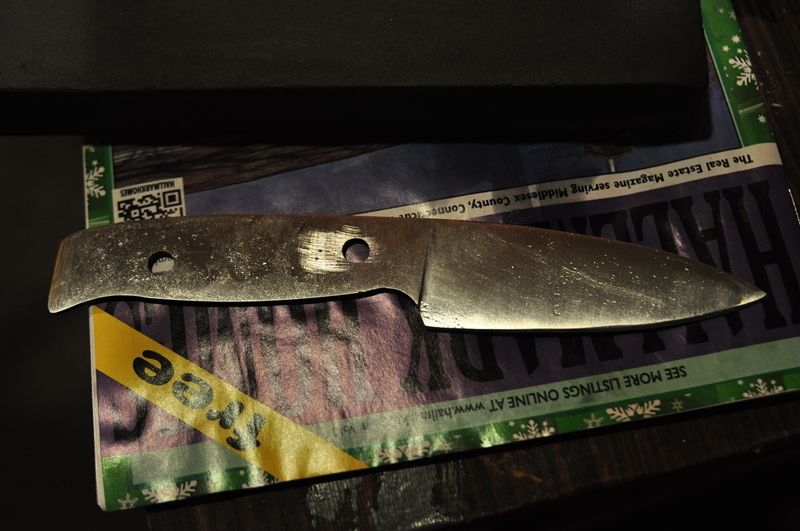

I started with the pocket blade first, as I figure it'd be better to practice on. I ground off most of the oxidation (or whatever it is) from heat treating with a 220 belt and started the edge bevel when I realized it was going way too fast and coming out sloppy, so I took out an old "Carborundum" stone that was my dad's and went to town on the coarser side. After a few minutes, I put a piece of paper to the edge and it sliced through. The revelation hit me right then and I said to myself "I'll be damned. That's a knife."

It needs a little more work on the edge, and eventually will be finished off on my 701 Profiles. There are a few heat treating marks left on the blade but I think I'll leave them for a more rustic look (and cuz I'm lazy). And of course, it needs a pair of my signature cutting board handle scales. It's not Spyderco quality. The lines and curves aren't great, the holes are anything but inline, and the edge is pretty ugly, but for my first, I'm pretty darn proud.

It's been a really fun project and I can't wait to get them both finished. I really hope the chef knife comes out nice so I can cross someone off my Christmas list! I highly recommend this hobby to anyone who's thinking about trying it. I thoroughly enjoyed myself, learned a lot so far, and am thrilled that I got something usable out of it. Hence my sharing with ya'll! :D