I have read online spec sheets that list the assorted elements/atoms that make up H1 stainless steel, and I have read the list of these ingredients in a book on knives. Here is my question: What is stopping some company in America, Europe, or elsewhere, from compiling and collating this list of the elements that go into H1 stainless, and making their own reverse engineered batches of the stuff, and using it for knives and other tools and items? Is this possible to do or is the proprietary secret likely in the proper percentages of these elements and how they are treated? Does anyone here predict or expect we will see other countries and companies outside of Japan reverse engineering and making use of H1 and variations of it in coming years?

As an example, there was a time when steels such as 440 series, and 154 CM were known only to a handful of engineers and knife-makers, and then as time went on, others got into the production and engineered their own batches and variations of it. Should we expect the same thing to happen with H1, depending on the marketability, and in some years from now see catalog pages and websites full of assorted knives sporting H1 steel blades?

H1 Steel and other Knife Makers question

- SpyderEdgeForever

- Member

- Posts: 6325

- Joined: Mon Jul 23, 2012 6:53 pm

- Location: USA

-

yablanowitz

- Member

- Posts: 6909

- Joined: Sun Apr 09, 2006 2:16 pm

- Location: Liberal, Kansas

Re: H1 Steel and other Knife Makers question

The only thing stopping others from copying H-1 is the expense. The components are known or can be determined fairly easily. The tricky part is the processes involved. Fifty years from now, people will look at H-1 and say "That's quaint. Was it really considered better than bronze?"

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: H1 Steel and other Knife Makers question

What exactly are you referring to?yablanowitz wrote:The tricky part is the processes involved.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: H1 Steel and other Knife Makers question

Steels are patented, just making a copy of a steel violates that patent. It also isn't possible to make a "similar" steel by slightly adjusting the percentages because patents on steels are generally really wide and cover large ranges of both composition and manufacturing.SpyderEdgeForever wrote:Is this possible to do or is the proprietary secret likely in the proper percentages of these elements and how they are treated?

That being said, there are lots of work hardening stainless steels available, almost every manufacturer makes some variant of them as well as precipitation hardening (aging). To start look at the 300 series which is the work horse of the austenitic stainless steels.

- SpyderEdgeForever

- Member

- Posts: 6325

- Joined: Mon Jul 23, 2012 6:53 pm

- Location: USA

Re: H1 Steel and other Knife Makers question

Regarding the 300 series of stainless steels, Cliff, I have seen various diving knives made with 304 steel. But some knife users claim 304 stainless, at least on the ones I have seen for sale, is very rust resistant but horrible as far as edge-holding and strength goes. Does this tend to be your analysis?

Also, as you have pointed out, 420 steel seems to vary. Some variants of it are good and others not so good. One guy told me "Good 420 steel needs to have HC for High Carbon after it, or you cannot trust it to be reliable."

Also, as you have pointed out, 420 steel seems to vary. Some variants of it are good and others not so good. One guy told me "Good 420 steel needs to have HC for High Carbon after it, or you cannot trust it to be reliable."

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: H1 Steel and other Knife Makers question

304 stainless has less than 0.1% C and no nitrogen and a high amount of nickel so it is an austenitic stainless steel. It is usually classified as a non-hardenable steel meaning it doesn't respond to normal heat treatments. However the exact same elements (nickel) also means it work hardens strongly just like H1. In regards to edge holding that is far more dependent on the geometry and the edge finish and sharpness than the steel. I have made knives out of 1010 mild steel which have easily had better edge retention on hemp rope for example than custom/production knives in "high end" steels. The reason being the mild steel knife had an edge ground to be ideal for cutting rope.SpyderEdgeForever wrote:But some knife users claim 304 stainless, at least on the ones I have seen for sale, is very rust resistant but horrible as far as edge-holding and strength goes.

420 is a pretty broad label so it is hard to know what someone means. 420J1 and 420J2 are two distinct steels as is 420HC. As the carbon content is increased then :Also, as you have pointed out, 420 steel seems to vary. Some variants of it are good and others not so good. One guy told me "Good 420 steel needs to have HC for High Carbon after it, or you cannot trust it to be reliable."

-corrosion resistance is reduced

-ductility and impact toughness is reduced

-working hardness and wear resistance is increased.

If you took 420J1 and added nickel you would have a steel very close to H1. Note that the nitrogen in H1 is a martensite former just like carbon so you can just add the two of them and consider that to be the "effective" carbon content. Just realize that nitrogen will enhance corrosion resistance but carbon does not. Hence why if you can afford it, adding nitrogen to replace carbon tends to make a steel "better" if corrosion resistance is a concern.

Re: H1 Steel and other Knife Makers question

Cliff Stamp wrote:What exactly are you referring to?yablanowitz wrote:The tricky part is the processes involved.

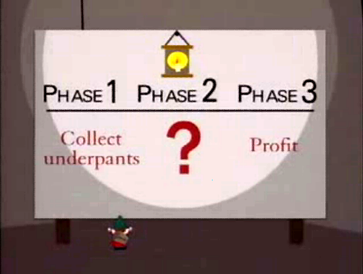

I'm pretty sure he was referring to Phase 2. Phase 2 is always the trickiest!