Sharpening Strokes

Sharpening Strokes

I know at least a couple of forumites must have studied the following questions:

"Does it make any difference what direction you move your blade while sharpening?"

For instance, is there any discernible difference in:

"pushing" the blade in a slicing motion, secondary bevel leading

<OR>

"drawing" the blade with secondary bevel trailing

<OR>

combining both motions alternately

<OR>

some other variation like a "scrubbing" motion

<OR>

or even perhaps a circular "orbital" motion

Basically-- do any of the motions benefit or detract from the sharpening experience or subsequent blade performance?

"Does it make any difference what direction you move your blade while sharpening?"

For instance, is there any discernible difference in:

"pushing" the blade in a slicing motion, secondary bevel leading

<OR>

"drawing" the blade with secondary bevel trailing

<OR>

combining both motions alternately

<OR>

some other variation like a "scrubbing" motion

<OR>

or even perhaps a circular "orbital" motion

Basically-- do any of the motions benefit or detract from the sharpening experience or subsequent blade performance?

Re: Sharpening Strokes

I'm sure Cliff himself can chime in, but he did a vid on sharpening with a very coarse stone, and he alternated "pushing" and "drawing" to mix up the scratch pattern. Not sure if it matters once you get past a certain grit, though.

- bearfacedkiller

- Member

- Posts: 11412

- Joined: Sat Jan 04, 2014 1:22 pm

- Location: hiding in the woods...

Re: Sharpening Strokes

I was taught as a kid that you always pull the knife towards you while sharpening so that you create "teeth" that point in the direction of the cut which makes it both cut more aggressively and makes it stay sharp longer. I now always sharpen in that direction just out of habit. I assume that as the grit gets finer that this effect would be diminished and begins to be less important if it even makes a difference at all.

-Darby

sal wrote:Knife afi's are pretty far out, steel junky's more so, but "edge junky's" are just nuts. :p

SpyderEdgeForever wrote: Also, do you think a kangaroo would eat a bowl of spagetti with sauce if someone offered it to them?

Re: Sharpening Strokes

I believe most people push the edge towards the stone rather than pulling the edge. If you are using a strop, or sandpaper on a mouse pad, then you pull the edge. The sharpmaker is invented predomonately for the pushing motion although I've also seen videos where they alternated pushing and pulling, essentially rubbing the edge back and forth along the stone.

I have a theory that it is easier to remove a burr if you are pushing rather than pulling but I can't prove it.

I have a theory that it is easier to remove a burr if you are pushing rather than pulling but I can't prove it.

Re: Sharpening Strokes

I'm strictly edge leading and avoid trailing like the plague. It doesn't even matter to me if it matters in actual use, what I know is years ago when I was learning the basics this made a huge improvement for me so I stuck with it.

Re: Sharpening Strokes

thanks for the replies... :)

anything more analytic, less anecdotal? :confused:

anything more analytic, less anecdotal? :confused:

Re: Sharpening Strokes

I find your subject of freehand sharpening interesting because here lately I've been doing a lot of stuff with my Spyderco 302 Benchstones and I have all three grits as well.

Now there is a lot to be said for the skill of freehand sharpening and I encourage all of you to at least give it a try. But "Razor Edge Systems" company out of Ely, Minnesota has some fine sharpening tools that I think could help many people using flat benchstones. Razor Edge Systems sells a "clamp-on sharpening guide" for small and large blades. I've been having terrific results using them especially on a couple of fixed blade models.

As much as I love the 204 Sharpmaker I will still never give up on using benchstones and Spyderco's 302 stones are great.

Now there is a lot to be said for the skill of freehand sharpening and I encourage all of you to at least give it a try. But "Razor Edge Systems" company out of Ely, Minnesota has some fine sharpening tools that I think could help many people using flat benchstones. Razor Edge Systems sells a "clamp-on sharpening guide" for small and large blades. I've been having terrific results using them especially on a couple of fixed blade models.

As much as I love the 204 Sharpmaker I will still never give up on using benchstones and Spyderco's 302 stones are great.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Sharpening Strokes

It depends on if you are talking about removing material to change the shape of the blade vs setting the finish of the apex. For grinding the blade bevel or edge bevel it makes little difference aside to ergonomic and control issues. Therefore when you are just removing material for shape purposes you grind in whatever way you find comfortable and can do with some measure of control.paladin wrote:

Does it make any difference what direction you move your blade while sharpening?

However when you set the apex the orientation of the stone has a number of effects :

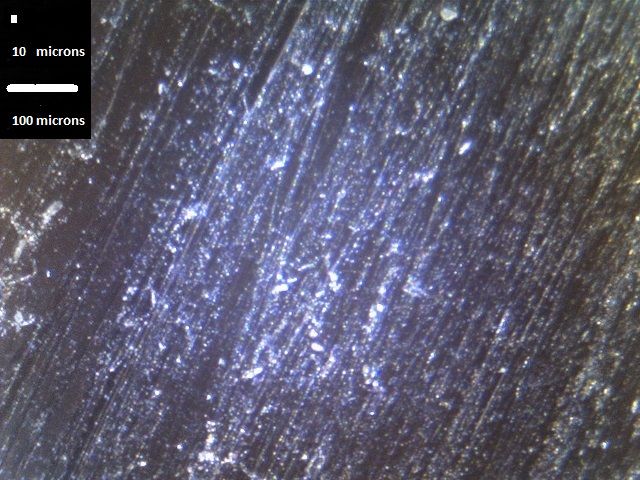

This is the scratch pattern from a #320 waterstone. Note that most of the scratches are in one direction, the odd hazy bits are the random marks from the slurry. It should be easy to understand why you would not want deep scratches running along the apex as they can make it snap off. The orientation of the scratch pattern can influence the angle of attack of the points which form on the edge just like the teeth on a saw. As well you can cross cut the scratch pattern to refine the polish which also aid in burr minimization.

Re: Sharpening Strokes

Cliff Stamp wrote: The orientation of the scratch pattern can influence the angle of attack of the points which form on the edge just like the teeth on a saw.

...

As well you can cross cut the scratch pattern to refine the polish which also aid in burr minimization.

These 2 statements seem contradictory to me...I am sure I don't understand...please elaborate...thank you :)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Sharpening Strokes

I don't understand where you see the contradiction.paladin wrote:

These 2 statements seem contradictory to me.

The problem with sharpening is that you really can't see what is going on, it helps somewhat if you do some work with a very coarse grit, say #100 as that stone will leave scratches you can see by eye.

Imagine a wheel which cuts a serrated pattern in a knife. Now turn the wheel 45 degrees and run it again, what happens to the teeth, they get cut off and they will roughly be cut in two depth wise.

The same thing happens with abrasives and you can manipulate this to produce an apex which has a very low irregularity. It also can be manipulated by building up a slurry which will inherently randomize the scratch pattern.

Note here you can't even see any scratch orientation and thus with a heavy slurry the direction doesn't matter at all. That is the same grit stone as in the above, the only difference is one has a very heavy slurry and the other doesn't.

Re: Sharpening Strokes

It seemed contradictory to me because I assume forming teeth perpendicular to the very edge (like a saw) would be ideal according to what you stated...

Then, with the next statement you seem to imply that cross-scratching the teeth (parallel to the apex) would be beneficial...

Wouldn't those scratches, which are at a right angle to the "saw teeth," be weakening the base of the teeth themselves making them "snap off" prematurely, as you previously stated?

Please understand I am not being obtuse purposely, it just confused me... :confused:

Are you saying it is an ELU's choice between having well-formed, stable teeth <OR> a nicely refined edge, and never the twain shall meet? :confused:

Then, with the next statement you seem to imply that cross-scratching the teeth (parallel to the apex) would be beneficial...

Wouldn't those scratches, which are at a right angle to the "saw teeth," be weakening the base of the teeth themselves making them "snap off" prematurely, as you previously stated?

Please understand I am not being obtuse purposely, it just confused me... :confused:

Are you saying it is an ELU's choice between having well-formed, stable teeth <OR> a nicely refined edge, and never the twain shall meet? :confused:

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Sharpening Strokes

I wasn't very clear.paladin wrote:

Are you saying it is an ELU's choice between having well-formed, stable teeth <OR> a nicely refined edge, and never the twain shall meet? :confused:

If you form a burr then you have to cut it off, cross cutting the scratches can do that. This then sets the edge for the final apex bevel which isn't applied with cross scratching generally.

It is much easier to understand if you think on sharpening as two distinct steps :

-all shaping, when ends with the edge ready for an apex bevel

-applying the apex bevel

Re: Sharpening Strokes

understood now:

cross-scratching removes burr (if required)...

then form mirco saw-teeth...

thanks

cross-scratching removes burr (if required)...

then form mirco saw-teeth...

thanks

- Brunzenstein48

- Member

- Posts: 100

- Joined: Sat Apr 11, 2015 1:38 pm

- Location: Antananaivo

Re: Sharpening Strokes

Re: Sharpening Strokes

That quote is imho most important as I see a (more or less prominent) mirco saw-teeth as the ideal edge form for all real world tasks - opposite to polished edges which seems most proper for show, fairs or museum pieces.paladin wrote: then form mirco saw-teeth...

Am I wrong?

“It is not the strongest of the species that survives, nor the most intelligent that survives.

It is the one that is the most adaptable to change.”

Charles Darwin

It is the one that is the most adaptable to change.”

Charles Darwin

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Sharpening Strokes

It is one thing to take a position that you prefer a type of edge or steel, but it is a pretty radical position to infer the complete lack of utility of a difference. A highly polished edge has better cutting ability, durability, edge retention, ease of maintenance, corrosion resistance and blade lifetime - in push cutting. It is often therefore favored by wood workers, in kitchen cutlery and by butchers and others in the trade in meat work. People like John Juranich have made a career on selling tools to meat workers which apply/maintain a very high polished edge. When such work is done with a push cut, those edges do well.Brunzenstein48 wrote:....opposite to polished edges which seems most proper for show, fairs or museum pieces.

An interesting contrast is to look at, and this is a loose generalization, the difference between Western and Japanese cutlery. There is a large difference in the blades and steels which tends to make for differences in both use and maintenance. It isn't that uncommon for Western blades to be maintained with a fine diamond abrasive or coarse butchers rod but Japanese knives tend to be finished on much higher grits even for the same work. This is due to the difference in cross section which produces different cutting strokes and differences in steel and HT which effect maintenance.

Western cutlery can be typically ~55 HRC, the edges can be as high as 0.030"/20 dps. The thicker profile tend to make sawing motions necessary, more force to be applied which means more damage on accidental contacts. The softer hardness and very low alloy tends to reduce edge retention, especially at high polishes and even make them not trivial to apply. But it also means that a decent sharpness can be restored with just a few hard rakes down a coarse butchers rod.

In contrast Japanese kitchen knives typically run higher carbide steels (White/Blue), the hardness is usually far above 60 HRC, the edges are typically 0.005"/15 dps and this produces a very different cutting motion. They can hold a high sharpness well, they are trivial to get to a very high polish sharpness and if you raked them hard down a butchers rod you would likely chip the edge out.

- Brunzenstein48

- Member

- Posts: 100

- Joined: Sat Apr 11, 2015 1:38 pm

- Location: Antananaivo

Re: Sharpening Strokes

With all due respect to you as an seasoned expert Cliff - I question that statement.Cliff Stamp wrote:A highly polished edge has better cutting ability, ease of maintenance, corrosion resistance and blade lifetime ...Brunzenstein48 wrote:....opposite to polished edges which seems most proper for show, fairs or museum pieces.

Your statement is certainly not true for all material to cut and how to cut them - there is bigger world out there Cliff!- try cutting a rose stem, a soft cheese, a steak, a fat pork belly's skin (everything but a saw blade style will slip of) or a ripe tomato and you will be momentarily enlightened.

The usual (and imho stupid) mile-long cardboard cutting adventure trumpeted as a true measurement for edge retention e.g. is producing results, not necessarily reflecting the real world.

“It is not the strongest of the species that survives, nor the most intelligent that survives.

It is the one that is the most adaptable to change.”

Charles Darwin

It is the one that is the most adaptable to change.”

Charles Darwin

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Sharpening Strokes

Read the entire statement :Brunzenstein48 wrote:Your statement is certainly not true for all material to cut and how to cut them...

Cliff Stamp wrote: A highly polished edge has better cutting ability, durability, edge retention, ease of maintenance, corrosion resistance and blade lifetime - in push cutting.

This isn't the first time you try to imply that I am speaking due to lack of experience cutting. I rarely talk about the work I do specifically in these kinds of discussions, however since you keep bringing it up - take all the material that you have cut up and think about the amount of work you have done with it. Now realize that with any random material you can think on I have likely cut more of that just one material than you have cut with the sum total of everything you have cut. I have also done it with more careful comparisons looking at geometry, finish, sharpness, speed, force, etc. all quantified and random sampling. And this is only the controlled experiments, I have done even more cutting just in general use. I also loan out all of my knives constantly, they are always on passaround and I have a huge pool of data coming in from that and this has been going on for DECADES.- there is bigger world out there Cliff!- try cutting a rose stem, a soft cheese, a steak, a fat pork belly's skin (everything but a saw blade style will slip of) or a ripe tomato and you will be momentarily enlightened.

Yes I have cut plant matter. I have personal gardens, I maintain multiple cemetery plots and I do a lot of dead-fall harvesting and brush work in general. Yes I have cut a lot of meat and fats. I live in a rural area. I don't buy cuts of meat. I get whole fish from actual fishing. I get large cuts of pork, beef, moose and bear from hunted animals. If you want to talk about performance then fine, but drop the condescension about lack of experience. It adds nothing to the conversation, even if it was true it is a logical fallacy (he who has cut he most material is not necessarily he who knows the most, or anything about cutting so making arguments about who has done what or more/less is meaningless) and it is simply silly because I have been talking about this work on line and sharing knives with others for DECADES.

The ironic thing about this is that cardboard cutting is usually done on a draw hence it benefits from a coarse edge. Thus long cardboard trials done on a slice and those who favor them tend to promote use of low grit edges. Spyderco by the way bought a CATRA tester which cuts cardboard as a way to obtain edge retention data. It is a fairly curious argument to make on their board that is a stupid thing to do. Buck also uses such data as do a few other of the manufacturers.The usual (and imho stupid) mile-long cardboard cutting adventure trumpeted as a true measurement for edge retention e.g. is producing results, not necessarily reflecting the real world.

The reason why a large amount of cardboard has to be cut is that with a knife properly sharpened, it takes about 1 km of cardboard to blunt an edge to the point it won't slice paper even with a very basic steel like 420. If you cut less than that and compare you are looking at edge retention at very high sharpness levels. This can be useful, however you just need to be clear on what you are talking about. This is why on a CATRA machine you can set the cycle number. It is generally set to 60 which produces a very low sharpness which is what most of the CATRA numbers (TCC) represent.

A lot of other makers use ropes instead of cardboard, Joe Calton, David Boye, Jimmy Fikes for example. Rope is more consistent than cardboard and cleaner to cut (less dust/dirt). However if it is cut on a slice then it correlates well to cutting cardboard on a slice as they blunting mechanisms are similar. If it is cut on a push, well it correlates well to cardboard cut on a push for the same reasons. Again, it is the push/slice which is important as to if low or high grit edges perform well. Hence why Jimmy Fikes uses a high polish (he push cuts) and Joe Calton uses a lot grit finish as he slices.

As knives get ground so as to more optimize the cutting ability less of a draw is needed, hence apex finishes tend to end up being very polished. This is why makers like Alvin Johnson exclusively used very high polish finishes as he hollow ground to very thin edges and finished at very low angles (< 0.005"/10 dps). And yes, he cut meats, he hunted and he made knives for professional butchers.

Again it depends on how you cut. This is why a lot of hunters like the Havolon blades for butchering as they do push cuts in cleaning. It is also why some Japanese style fish work is done with a high polish and Wester style fish work usually uses a much more coarse finish. Japanese style work is mainly push cutting, Western is mainly slicing and that combined with the softer steels lends itself to coarse edges, common with a butchers rod.