Is SuperBlue and Ultra High Carbon Steel the same?

- SpyderEdgeForever

- Member

- Posts: 6325

- Joined: Mon Jul 23, 2012 6:53 pm

- Location: USA

Is SuperBlue and Ultra High Carbon Steel the same?

I have been reading about what are called "Ultra High Carbon Steels", very fascinating things. Some references claim that UHCS is quite ancient, going at least as far back as the Wootz "Damascus" steel, and other info says UHCS factors heavilly in with modern powder metallurgy production.

I have also studied a bit about Japanese "White" and "Blue" steels, and my question is this: Is the Spyderco Super Blue considered an Ultra High Carbon Steel? A Finnish knife maker named Roselli uses it in one of their fixed blade hunting knives, the UHCS.

Here is a video I found with Murray Carter explaining the white and blue steels:

https://youtu.be/aXlgtpjSyM0" target="_blank

Wikipedia states this:

"

Ultra-high-carbon steel

Approximately 2.5–3.0% carbon content.[1] Steels that can be tempered to great hardness. Used for special purposes like (non-industrial-purpose) knives, axles or punches. Most steels with more than 2.5% carbon content are made using powder metallurgy. Note that steel with a carbon content above 2.14% is considered cast iron."

From Ragweed Forge website:

" Also from Roselli is the UHC (Ultra High Carbon) line. This is a proprietary steel with a carbon content of 1.5 - 2.0%. It is hardened to HRC of 64 - 66 and is said to hold an edge twice as long as the already excellent regular line. "

And so, is the Spyderco Super Blue steel the same thing, or different from this UHCS?

I have also studied a bit about Japanese "White" and "Blue" steels, and my question is this: Is the Spyderco Super Blue considered an Ultra High Carbon Steel? A Finnish knife maker named Roselli uses it in one of their fixed blade hunting knives, the UHCS.

Here is a video I found with Murray Carter explaining the white and blue steels:

https://youtu.be/aXlgtpjSyM0" target="_blank

Wikipedia states this:

"

Ultra-high-carbon steel

Approximately 2.5–3.0% carbon content.[1] Steels that can be tempered to great hardness. Used for special purposes like (non-industrial-purpose) knives, axles or punches. Most steels with more than 2.5% carbon content are made using powder metallurgy. Note that steel with a carbon content above 2.14% is considered cast iron."

From Ragweed Forge website:

" Also from Roselli is the UHC (Ultra High Carbon) line. This is a proprietary steel with a carbon content of 1.5 - 2.0%. It is hardened to HRC of 64 - 66 and is said to hold an edge twice as long as the already excellent regular line. "

And so, is the Spyderco Super Blue steel the same thing, or different from this UHCS?

Re: Is SuperBlue and Ultra High Carbon Steel the same?

I understand UHC would be differentiating between stainless (low carbon like 420j2) and steels like ZDP-189, S90v, etc. HSS or high speed tool steels seem to be somewhere in the middle.

Steels like Hitachi white, blue, and superblue are as I understand just highly controlled carbon steels with trace elements for optimizing the grain and for small carbide formations (like Tungsten in SB). They treated a bit harder than the average 1085/1095/O-1, and so on.

I'm sure Jim and Cliff will chime in with better info shortly :)

Steels like Hitachi white, blue, and superblue are as I understand just highly controlled carbon steels with trace elements for optimizing the grain and for small carbide formations (like Tungsten in SB). They treated a bit harder than the average 1085/1095/O-1, and so on.

I'm sure Jim and Cliff will chime in with better info shortly :)

- bearfacedkiller

- Member

- Posts: 11412

- Joined: Sat Jan 04, 2014 1:22 pm

- Location: hiding in the woods...

Re: Is SuperBlue and Ultra High Carbon Steel the same?

Depends on the marketing department and their desired pitch.

I think this is largely subjective and vague.

Zdp has way more carbon than SB but it also has way more of all the other alloying elements which makes it kind of a relative thing. Super Blue is high for such a simple steel and zdp is high for a complex alloy.

I am still learning about this but soon enough someone more knowledgable will chime in and explain the part about carbide formation and whatnot.

I think this is largely subjective and vague.

Zdp has way more carbon than SB but it also has way more of all the other alloying elements which makes it kind of a relative thing. Super Blue is high for such a simple steel and zdp is high for a complex alloy.

I am still learning about this but soon enough someone more knowledgable will chime in and explain the part about carbide formation and whatnot.

-Darby

sal wrote:Knife afi's are pretty far out, steel junky's more so, but "edge junky's" are just nuts. :p

SpyderEdgeForever wrote: Also, do you think a kangaroo would eat a bowl of spagetti with sauce if someone offered it to them?

Re: Is SuperBlue and Ultra High Carbon Steel the same?

Other than general industry uses other than the knife industry it's more of a marketing ploy to sell knives, in this case low alloy non stainless knives, directed at those who like low alloy non stainless steel knives.

Some new buzz word.. "Ultra High Carbon Steel" .... We are supposed to go Oh WOW.... :rolleyes:

Without the carbides to add to the overall wear resistance there won't be that much of a difference between those and steels like Super Blue and 1095.

No carbide formers = No carbides, if the alloy isn't there it's just not there.

Every once in awhile someone tries to push the old Myths and Urban Legends to sell knives, this is just more of the same.

Some new buzz word.. "Ultra High Carbon Steel" .... We are supposed to go Oh WOW.... :rolleyes:

Without the carbides to add to the overall wear resistance there won't be that much of a difference between those and steels like Super Blue and 1095.

No carbide formers = No carbides, if the alloy isn't there it's just not there.

Every once in awhile someone tries to push the old Myths and Urban Legends to sell knives, this is just more of the same.

Re: Is SuperBlue and Ultra High Carbon Steel the same?

I've seen it as a disclaimer too. Bought some Kai Pure kitchen knives (like 6 for $30 at Costco :p) and they explained they should be "hand washed due to the high carbon stainless steel blades".

Re: Is SuperBlue and Ultra High Carbon Steel the same?

Blerv wrote:I've seen it as a disclaimer too. Bought some Kai Pure kitchen knives (like 6 for $30 at Costco :p) and they explained they should be "hand washed due to the high carbon stainless steel blades".

There is a lot of that going around. LOL :D

High Carbon steel

High Carbon Stainless Steel (Cheap Knives)

Ultra High Carbon Steel

Surgical Steel

It's just marketing really and people are supposed to go OH WOW THAT'S AWESOME..... ROFL

I would hope people on the Spyderco Forum would be smarter than to fall into those ploys.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Is SuperBlue and Ultra High Carbon Steel the same?

These things are defined they are not subjective/vague terms but each association defines them a bit differently there isn't some kind of NATO type organization which forces each country to use the same definitions. However according to AISI (American organization) then it is a ultra-high carbon steel as it has 1.4 to 1.5% carbon which is in the ultra-high range (above high carbon which is 0.6 to 1%) .SpyderEdgeForever wrote:Is the Spyderco Super Blue considered an Ultra High Carbon Steel?

UHCS is essentially very close to a pure carbon steel, it is similar to White #1 which is a Japanese steel, or W1 which is a US tool steel. SuperBlue has a similar carbon content but it has significant other alloy which influences hardenability, aus-grain and wear resistance (it has 2 to 2.5% tungsten and 0.5% vanadium which together are about 1% vanadium in regards to abrasive wear).And so, is the Spyderco Super Blue steel the same thing, or different from this UHCS?

Aside from the things which are important to a maker, SuperBlue thus has lower apex stability, lower toughness but higher low stress abrasive wear than White #1. Which one is better depends on which of these properties are more important. White will take a lower angle, hold a higher sharpness longer but SuperBlue will hold a lower sharpness longer.

However these are fine differences, it is sort of like saying an olympic sprinter runs faster than a college sprinter. This is true absolutely, but it doesn't mean that top college sprinters are slow and pretty much if everything else isn't equal you likely would have trouble telling them apart because the differences are so small.

Not really, it is referring to a very specific steel, it isn't a sort of marketing term like "surgical stainless".Blerv wrote:I understand UHC would be differentiating between stainless (low carbon like 420j2) and steels like ZDP-189, S90v, etc. HSS or high speed tool steels seem to be somewhere in the middle.

The use of UHC from Roselli is not new, they have been advocating it for awhile, again it is similar to Japanese White #1, which is not really in between 420J2 and S90V. It would be like saying that a track and field sprinter is athlete in between a ping pong player and a powerlifter. If you say what exactly you are "in betweening" then you can rank steels that way, but it doesn't make sense in general because you can make any kind of such comparison by just switching around what you are ranking.

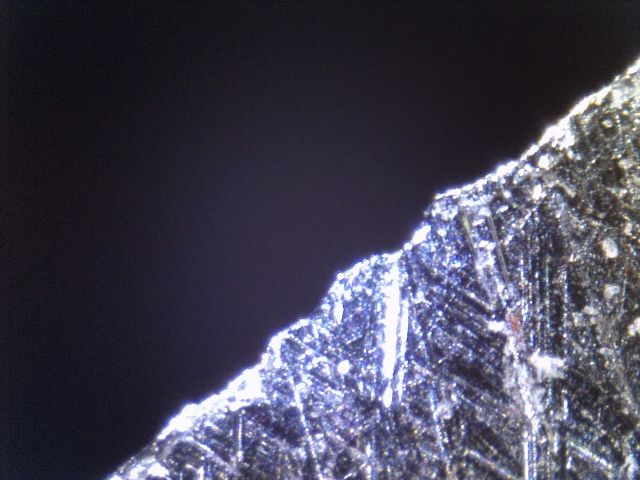

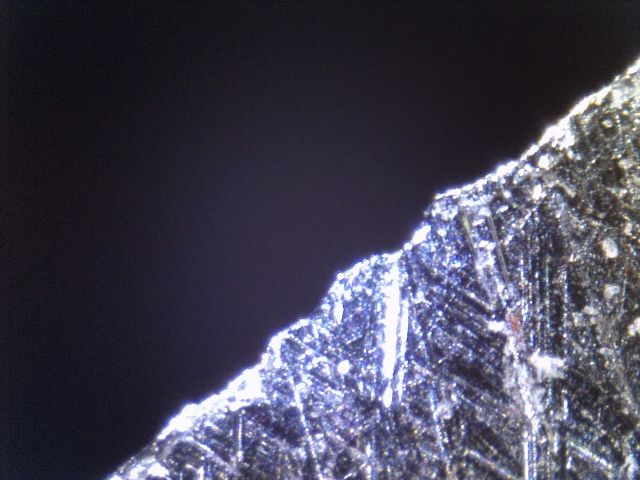

Iron is a carbide former, all of the hyper eutectoid steels are full of carbide. Hence why they look like this :Ankerson wrote:

[...]

No carbide formers = No carbides, if the alloy isn't there it's just not there.

That is DIN 12206, a 1.5% carbon steel, the white globs are carbide. The carbide will be of various forms depending on the exact tempering. If there is cryo then there will be eta-carbine and transitional forms as well as cementite, it depends on how it is tempered.

Re: Is SuperBlue and Ultra High Carbon Steel the same?

Depends on the actual alloy content, other carbide formers that are in the steel on how stable the cementite will be and how much of an effect it will have overall.Cliff Stamp wrote:SpyderEdgeForever wrote: Iron is a carbide former, all of the hyper eutectoid steels are full of carbide. Hence why they look like this :

That is DIN 12206, a 1.5% carbon steel, the white globs are carbide. The carbide will be of various forms depending on the exact tempering. If there is cryo then there will be eta-carbine and transitional forms as well as cementite, it depends on how it is tempered.

Also depends on what one is talking about, cast iron, simple carbon steels, tool steels etc and it will vary greatly.

So the statement loaded with carbides isn't exactly accurate and goes to the reason why iron carbides aren't usually a major factor compared to the more stable carbide formers so we generally don't even talk about those.

- All-R-Crazy

- Member

- Posts: 159

- Joined: Wed Feb 26, 2014 7:25 pm

- Location: IN , USA, EARTH

Re: Is SuperBlue and Ultra High Carbon Steel the same?

I learn a lot from threads like this one so keep going :)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Is SuperBlue and Ultra High Carbon Steel the same?

Jim, these words have meanings, as noted in the micro-graph in the above those steels are very high in carbide volume because iron is a carbide former. Iron carbide is also extremely hard, much harder than the steel and even significantly harder than even Novaculite for example which is a common sharpening abrasive.Ankerson wrote:

So the statement loaded with carbides isn't exactly accurate ...

The difference in hardness between iron carbide and even full hard martensite (66/67 HRC) is so large that the carbide is essentially incompressible and invulnerable to wear compared to the steel around it when cutting regular materials such as wood, ropes, cardboard, foods, etc. . A localized force on the carbides will not compress the carbide it will just push the carbide into the martensite, similar attempts to wear the apex will produce a differential wear on the steel and the carbide will just come out.

Hence why that class of steel will tend to blunt to a more jagged edge than a much lower carbide steel such as 52100 which will wear much smoother as the carbide volume is much less. Now this doesn't mean that White #1 is a better steel than 52100, it is better/worse depending on what properties are required no different than A2 vs D2. R. J. Martin was very fond of A2 in knives, Dozier of D2 and they both made very nice knives from it, but they desired very different things.

52100 has a higher apex stability, higher toughness and higher grind ability, White #1 has higher low stress abrasion. If you were willing to work with a lower sharpness, preferred to do slicing cuts, use a more coarse finish etc. . you would prefer White #1 over 52100. If you take this one step further then you would prefer Super Blue over White #1. If you take it another step further (very large one) you would prefer D7 over Super Blue. If you take an extreme step of this type forward you would prefer the carbide replacements over D7. If you take another step further you would prefer solid ceramic blades which can hold a very low sharpness for an extremely long time hence why they CATRA to insane levels, an order of magnitude above steels.

This however doesn't mean ceramic blades >> carbide replacements >> D7 >> Super Blue >> White #1 >> 52100 . As noted, it depends on what properties are important to the ELU. If the ELU is looking for retaining a high sharpness, trying to maximize cutting ability, wants high ease of sharpening, etc. that list reverse completely. If they want some kind of blend of properties then the list will work from the center out.

Re: Is SuperBlue and Ultra High Carbon Steel the same?

Cliff Stamp wrote:

The difference in hardness between iron carbide and even full hard martensite (66/67 HRC) is so large that the carbide is essentially incompressible and invulnerable to wear compared to the steel around it when cutting regular materials such as wood, ropes, cardboard, foods, etc. .

Between 40 and 70 HRC depending on what it is from my references.

Re: Is SuperBlue and Ultra High Carbon Steel the same?

What is between 40 & 70 HRc, cementite or martensite?

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Is SuperBlue and Ultra High Carbon Steel the same?

In regards to hardness, carbides can not even be measured in HRC, it isn't like you can HRC those iron carbides in White Steel which are far smaller than the indentor. HRC is a measure of bulk hardness of a solid. There are measurements of micro-hardness extrapolated back, but the actual hardness is dependent on how the strain is applied as it is a crystal structure so it depends on the axis loading, see for example Microhardness of cementite, Yu. N. Taran, V. I. Novik. It also depends on what else is in the cementite and again there are many forms of iron carbide in steels, cementite is only one of them.

In regards to hardness of various carbides, if you replace all of the iron carbide in White #1 with tungsten carbide it will indeed have a significantly higher low stress abrasive wear test with typical measurements. Why is this the case? Typical wear tests include things like drum sand abrasion tests where the sand is aluminum oxide being grated against the steel by a big drum. Aluminum oxide is a sharpening abrasive (the dominant one in fact) and will not only cut martensite, it can cut iron carbide (and most alloy carbides) but will struggle to cut vanadium carbide and thus the depth of cut will be reduced. Further if the alumina is very small, similar in size to the vanadium carbides then you can see a dramatic change in the rate of volume wear as the vanadium carbide will start cutting the alumina readily. However this has almost no relevance to knives unless you are using them to cut up sandpaper.

Most materials that you cut won't be strong/hard enough to abrade the martensite (or even pearlite), let alone the iron carbide, hence wear is really, really slow and blunting tends to take place more so by deformation/fracture and corrosion. Here is the edge on a 3Cr13 stainless steel knife, < 55 HRC which has had ~2000 slices into 1/2" hemp :

The hemp can't even wear away the martensite significantly which would be expected. If this doesn't immediately jump out to you then try to polish a coarse scratch out of a blade with a piece of hemp rope.

This is why of course people using White #1 and similar steels rarely criticize the lack of edge holding performance, they are typically praised for it and in wood working for example will be ranked similar to HSS tools and far above for example D2 which has significant chromium and vanadium carbide (but much lower apex stability). Hardening and of course geometry are key, a White #1 steel at 60 HRC full of retained austenite and a large aus-grain isn't going to impress much of anyone. But again, if you are grinding ores and in general cutting much harder materials, then HSS will readily outperform HCS, just like carbide will out perform HSS, assuming of course the critical strain isn't exceeded.

In regards to hardness of various carbides, if you replace all of the iron carbide in White #1 with tungsten carbide it will indeed have a significantly higher low stress abrasive wear test with typical measurements. Why is this the case? Typical wear tests include things like drum sand abrasion tests where the sand is aluminum oxide being grated against the steel by a big drum. Aluminum oxide is a sharpening abrasive (the dominant one in fact) and will not only cut martensite, it can cut iron carbide (and most alloy carbides) but will struggle to cut vanadium carbide and thus the depth of cut will be reduced. Further if the alumina is very small, similar in size to the vanadium carbides then you can see a dramatic change in the rate of volume wear as the vanadium carbide will start cutting the alumina readily. However this has almost no relevance to knives unless you are using them to cut up sandpaper.

Most materials that you cut won't be strong/hard enough to abrade the martensite (or even pearlite), let alone the iron carbide, hence wear is really, really slow and blunting tends to take place more so by deformation/fracture and corrosion. Here is the edge on a 3Cr13 stainless steel knife, < 55 HRC which has had ~2000 slices into 1/2" hemp :

The hemp can't even wear away the martensite significantly which would be expected. If this doesn't immediately jump out to you then try to polish a coarse scratch out of a blade with a piece of hemp rope.

This is why of course people using White #1 and similar steels rarely criticize the lack of edge holding performance, they are typically praised for it and in wood working for example will be ranked similar to HSS tools and far above for example D2 which has significant chromium and vanadium carbide (but much lower apex stability). Hardening and of course geometry are key, a White #1 steel at 60 HRC full of retained austenite and a large aus-grain isn't going to impress much of anyone. But again, if you are grinding ores and in general cutting much harder materials, then HSS will readily outperform HCS, just like carbide will out perform HSS, assuming of course the critical strain isn't exceeded.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Is SuperBlue and Ultra High Carbon Steel the same?

If you want a really nice read which talks about not only the history but also modern applications of UHCS then read "The Evolution of Ultrahigh Carbon Steels - From the Great Pyramids, to Alexander the Great, to Y2K" by Jeffrey Wadsworth. He talks about how UHCS steels can have superplasticity (extremely high levels of ductility) and how laminates of UHCS and mild steel can have severely high toughness. These properties are exploited now in industry and may be one of the reasons why it was so prized in the Wootz/Bulat swords.SpyderEdgeForever wrote:I have been reading about what are called "Ultra High Carbon Steels", very fascinating things. Some references claim that UHCS is quite ancient, going at least as far back as the Wootz "Damascus" steel, and other info says UHCS factors heavilly in with modern powder metallurgy production.

However you should be aware that the way that manufacturers such as Roselli are not hardening those steels to produce those kinds of behaviors. They are doing a fairly straightforward hardening to produce very high strength and wear resistance. This is why people talk about White steels in Japanese kitchen knives for things like high sharpness/edge retention, not extreme toughness/durability.

Re: Is SuperBlue and Ultra High Carbon Steel the same?

It's always a pleasure to read Cliff's scientific, experimental and academic approaches to these topics. Research, then test :D. Every thread I read leaves me understanding a little bit more :D

Charlie

Charlie

- SpyderEdgeForever

- Member

- Posts: 6325

- Joined: Mon Jul 23, 2012 6:53 pm

- Location: USA

Re: Is SuperBlue and Ultra High Carbon Steel the same?

[quote="Cliff Stamp"]

If you want a really nice read which talks about not only the history but also modern applications of UHCS then read "The Evolution of Ultrahigh Carbon Steels - From the Great Pyramids, to Alexander the Great, to Y2K" by Jeffrey Wadsworth. He talks about how UHCS steels can have superplasticity (extremely high levels of ductility) and how laminates of UHCS and mild steel can have severely high toughness. These properties are exploited now in industry and may be one of the reasons why it was so prized in the Wootz/Bulat swords.

Thank you so much, Cliff. I am looking for that book or one of his related books on the topic and it is very difficult to find, so far. Any leads on a place that sells that book?

Related question: If someone knew what they were doing, and had the right equipment, could they carefully add some other element, say, chromium, that would "stainlessize" the mix, without deleting its superplastic properties, or, would that essentially ruin the entire formula and make it into an altogether different steel?

If you want a really nice read which talks about not only the history but also modern applications of UHCS then read "The Evolution of Ultrahigh Carbon Steels - From the Great Pyramids, to Alexander the Great, to Y2K" by Jeffrey Wadsworth. He talks about how UHCS steels can have superplasticity (extremely high levels of ductility) and how laminates of UHCS and mild steel can have severely high toughness. These properties are exploited now in industry and may be one of the reasons why it was so prized in the Wootz/Bulat swords.

Thank you so much, Cliff. I am looking for that book or one of his related books on the topic and it is very difficult to find, so far. Any leads on a place that sells that book?

Related question: If someone knew what they were doing, and had the right equipment, could they carefully add some other element, say, chromium, that would "stainlessize" the mix, without deleting its superplastic properties, or, would that essentially ruin the entire formula and make it into an altogether different steel?

Re: Is SuperBlue and Ultra High Carbon Steel the same?

It depends? Steel alloying is complicated business. And the properties you're interested matter too. In a nutshell the arms race of stainless steels has one purpose: to make a steel that performs as well as high carbon steel but doesn't rust.

- quickster47

- Member

- Posts: 94

- Joined: Thu Sep 18, 2014 3:16 pm

- Location: Cumberland Cove, Monterey, TN

- Contact:

Re: Is SuperBlue and Ultra High Carbon Steel the same?

I found a paper with that title that cn be downloaded from this site:

http://www.osti.gov/scitech/biblio/756907" target="_blank

Carl

http://www.osti.gov/scitech/biblio/756907" target="_blank

Carl

SpyderEdgeForever wrote:Cliff Stamp wrote: If you want a really nice read which talks about not only the history but also modern applications of UHCS then read "The Evolution of Ultrahigh Carbon Steels - From the Great Pyramids, to Alexander the Great, to Y2K" by Jeffrey Wadsworth. He talks about how UHCS steels can have superplasticity (extremely high levels of ductility) and how laminates of UHCS and mild steel can have severely high toughness. These properties are exploited now in industry and may be one of the reasons why it was so prized in the Wootz/Bulat swords.

Thank you so much, Cliff. I am looking for that book or one of his related books on the topic and it is very difficult to find, so far. Any leads on a place that sells that book?

Gibbs rule #9. Never go anywhere without a knife.

Re: Is SuperBlue and Ultra High Carbon Steel the same?

For anyone who hasn't read the Wadsworth paper, it is very interesting. Of course now I'm trying to figure out how to get a Delica with a 1.8% carbon UHCS blade.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Is SuperBlue and Ultra High Carbon Steel the same?

The super plastic behavior comes from a formation that you likely would not want in a knife steel as it is dependent on having multiple phases and it is really only relevant at higher temperatures. However the article does talk about how the performance of a UHC steel can be severely influenced at room temperature by how it is hardened. Specifically it notes that two processing cycles, even though they give near identical hardness (66/67 HRC) have a significant range in both fracture strength and ductility (1 vs 10%). I think there is some interesting data there for people who are working in those steels and I think that alone can explain some of drastically wrong ideas some people have about those steels. As a point of reference :SpyderEdgeForever wrote:...If someone knew what they were doing, and had the right equipment, could they carefully add some other element, say, chromium, that would "stainlessize" the mix, without deleting its superplastic properties, or, would that essentially ruin the entire formula and make it into an altogether different steel?

Now there are manufacturers of steels which actually do take this approach and they do in fact make stainless steels for knives. See for example :Clearly, ultra-fine-martensitic UHCS would be exceptionally suitable in

wear resistant applications such as drill bits, industrial knives, and hand tools.

-http://patentimages.storage.googleapis. ... 274855.pdf

which is a patent application for Scandvik for a steel alloy for knives (and other cutting tools) : http://patents.justia.com/patent/20070274855" target="_blank . Note the commentary on carbide volume/size and how high amounts of allow carbide, especially vanadium will decrease performance. There is a wealth of data there, materials tests, micro-graphs and even CATRA testing.