mb1 wrote:Hey Cliff,

Do you just consider that a waste of metal if you can get an optimal apex before getting the burr?

The first thing to keep in mind about sharpening is that there is a big difference between wanting to get a knife sharp enough so that it just cuts more so than tears/rips and trying to get extreme levels of sharpness and edge retention. If you are just doing the former then a basic method which is :

-grind the edge to a burr

-flip the knife and repeat

-micro-bevel to finish

Is easy, simple and straightforward. But it has problems and this is why :

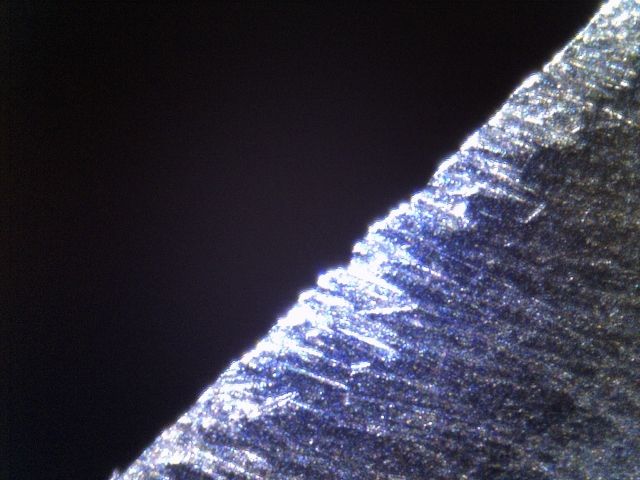

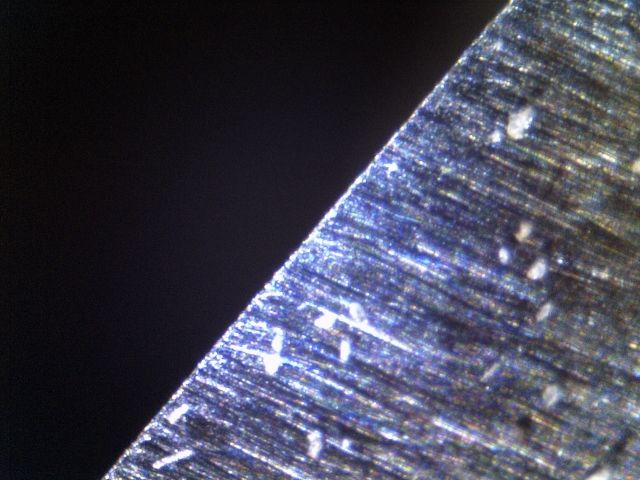

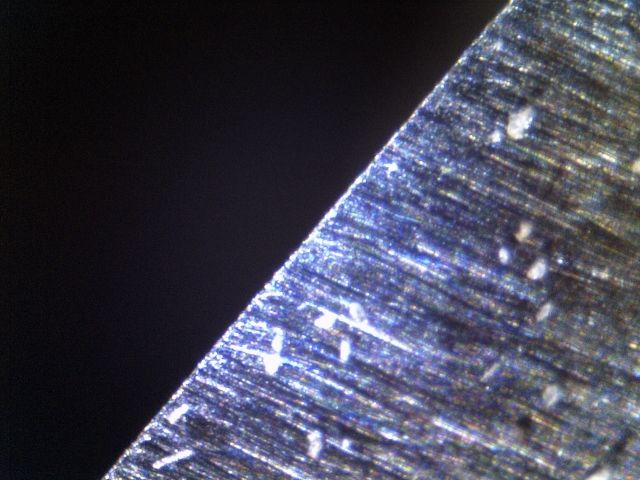

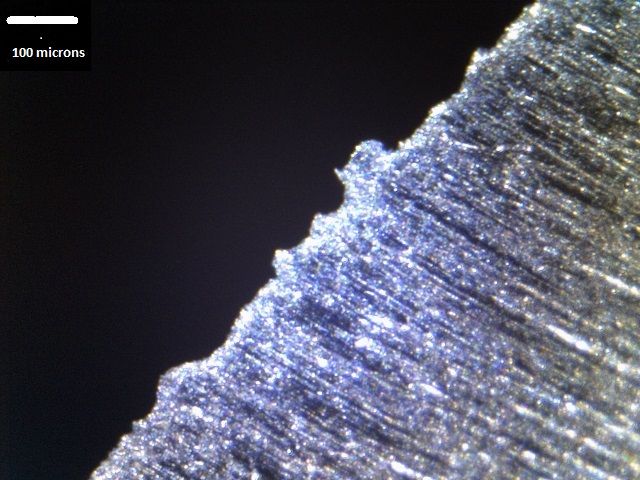

vs

This is the exact same stone used (Bester 700) with the same force, same amount of water. In the first picture it is stopped just before it hits an apex, in the second picture it is over ground and you can just barely feel a burr, just barely. But even with that small burr that you can't really see then it should be obvious that the apex itself is totally destroyed and that the damage is much deeper than the burr.

If you put a micro-bevel on both of these edges then they will seem similar in sharpness but the edge retention and durability is much higher on the first one. This difference in performance is MUCH larger than the difference in steels, it isn't even comparable. If you take for example a 420J2 knife with the first edge then it will easily outperform a M4 knife with the second edge carving wood, cutting cardboard, etc. . But unless you check it under magnification you are not likely to note the edge actually has an issue.

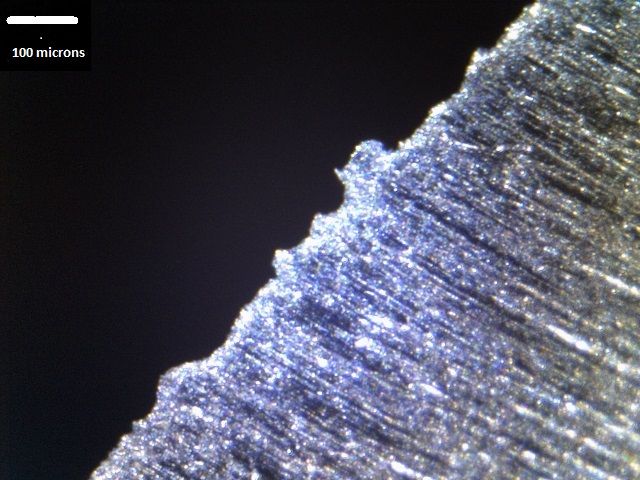

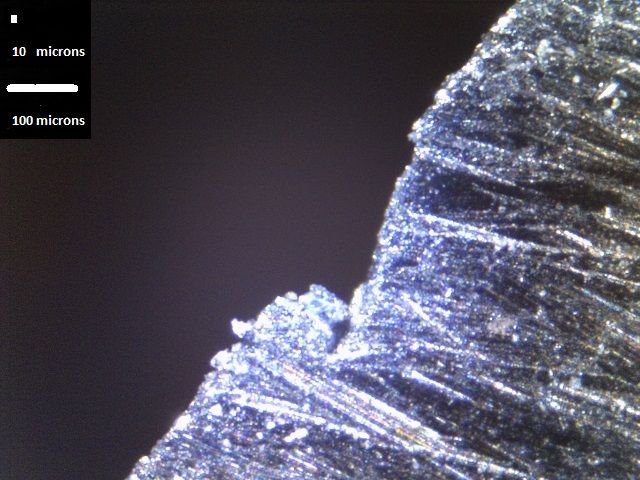

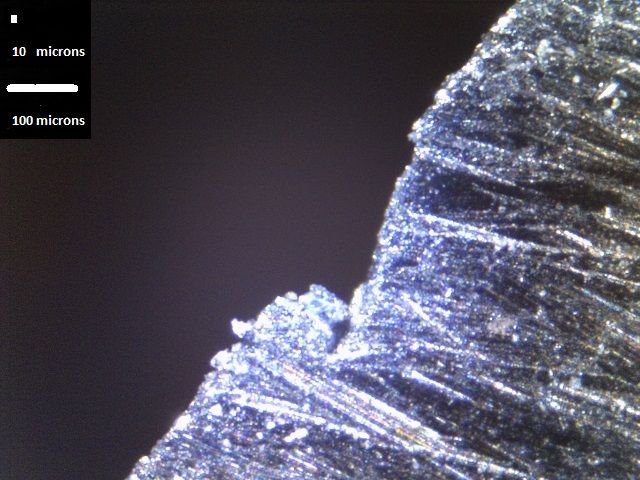

The Bester 700 isn't even a really coarse stone, this is what happens if you form a burr with an x-coarse stone :

Again this burr is just barely visible, it is tiny to your eyes and barely visible to your fingers. But keep in mind a sharpened apex is ~1 micron, that is one thousand of a mm. If you can see of feel a burr it is literally going to be 10-100X larger than the sharpened apex. If you want optimal performance then you have to remove all of that damage.

This is one of the core issues why a lot of people really have a pretty severe misunderstanding of what impressive means in regards to knife performance because what they have seen themselves is performance from edges which are often very poorly sharpened and have many issues such as :

-large stress cracks from heavy burr formation with coarse stones

-strained metal from previous work which was never removed

-an over buffed edge which rounded the apex

As just one example :

This is 4.5 KM, that is 4.5 kilometers of magazine paper cut with a 3Cr13 (420J2) knife at < 55 HRC and it didn't even take off the shaving sharp edge, yet a lot of people think cutting paper is hard on a knife edge, or that cardboard quickly dulls an edge. That same knife can easily cut a kilometer of cardboard or do a 1000 slices through 1/2" hemp and still slice a piece of paper smoothly.

The trick is however that the edge has to look like this before you put on the micro-bevel to set the apex :

not like this :

Those are again the exact same stones used, same knife, same edge angle, same everything, they are just used slightly differently. One uses a very muddy stone to bring the knife close to an apex but not over grind and form a burr. One uses a more wet stone for faster cutting and over grinds to form a barely visible burr. If you do any of the following :

-leave weakened metal on the edge

-over burr and round the apex

-form a very heavy burr and not remove it

then the performance will suffer, the knife will go dull rapidly, it will chip/deform much easier and in general be very low performance.

I would say though not to get so focused on this to the extreme that sharpening becomes some kind of chore or irritation. Just set a couple of goals and work towards them focusing on what you are trying to achieve with a decent understanding of what is happening. Note as well that while I don't try to form a burr, sometimes it happens. If it does then I cut it off on the stone and back bevel, this is also where people go off into weird places as they do lots of pretty odd things to remove it, many of which do as much damage or more than the burr itself :

-try to strop it off

-smash it off by scraping the knife through hardwoods

-get rid of it with a steel

These often make the problem worse as they can fold the burr back and forth until it cracks off, or simply smash it back into the apex itself both of which will further damage the edge. The sensible choice was noted by Jeff Clark on BF many years ago, which was also noted by Goddard in a very old knife sharpening article and is no more complex than this :

-elevate the edge angle a LOT, as in double or triple what you are using

-make 1-2 very light passes alternating sides

This cuts off the burr and you can continue sharpening as normal.