-sharpen a knife on a Wicked Edge/1000 grit diamond with a specific angle micro-bevel

-cut 1/2" hemp and periodically measure the sharpness

-determine the edge retention statistics

-repeat a few runs until stable

-then repeat this whole thing across a range of micro-bevel angles

-then repeat this whole thing again across a range of steels

-he work is blinded to prevent bias

The results of this comparison when finished allow you to answer some very interesting questions such as :

-At what angle do I need to sharpen 420J2 to have the same edge retention as as 21 dps - 1000 grit WE edge on S110V cutting half inch manilla hemp?

This question in fact many people don't even realize has an answer at all. In fact the more dramatic question :

-At what angle do I need to sharpen 420J2 to have twice the edge retention as as 21 dps - 1000 grit WE edge on S110V cutting half inch manilla hemp?

also likely has an answer as well because the influence of edge angle on edge retention is very large.

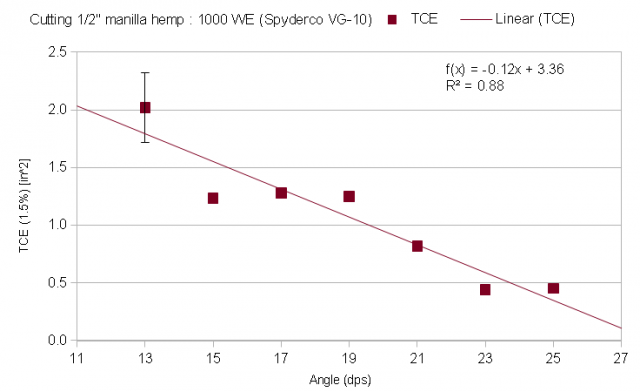

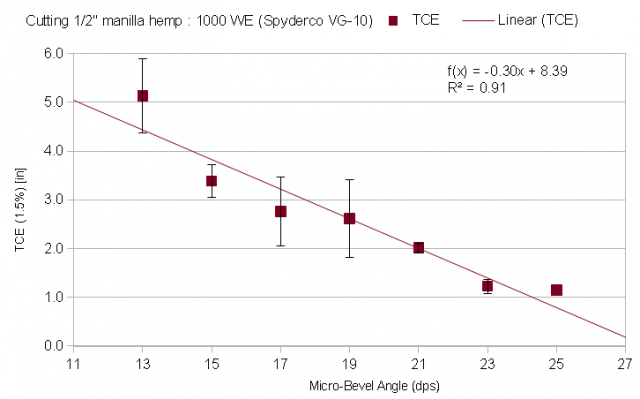

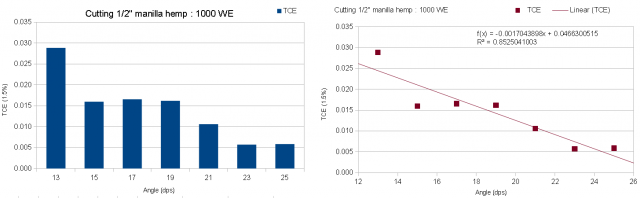

Here is one run only on a VG-10 blade from Spyderco (Lum Chinese) :

-primary grind full zero

-edge bevel is approx. 6.5 dps in the final sweep (slop from stone wear, not intentional)

I would like to get 11 dps, but it is not possible easily with the WE, I am going to play with this a little. In fact very low angles would be interesting because at some point the strength would be compromised and the apex would fail by lack of strength. However hemp is so soft that this takes very low angles, less than 5 dps.

Now before anyone reaches any dramatic conclusions from the particular shapes or relationship between one angle and another, again this is one run only I can not even bound the performance with error bars at this point. However there are still some obvious observations :

-the edge retention appears to depend critically on the edge angle

-further it decreases significantly as the micro-bevel angle is increased

-this change is so large that angle could be as critical (or more) than the steels

A lot of this I have discussed before, however the point to this is to move from these general statements to doing the work in enough volume to allow answering some very specific questions about steels and angles and at what point one can compensate for another.

It will take 3-5 runs before the measurements will stabilize and I think it should be a smooth trend. That large difference between 13 and 15 dps is likely just amplified by random scatter. This is a lot of work, just to compare two steels will take about 100 runs of cutting hemp so do not expect it any time soon.

As a final caveat, you can not generalize from this to edge retention in general. Hemp is so weak (compressible) that it can easily be cut with ultra-low angles in contrast hard wood cutting (plywood etc.) can easily turn edges at 10 dps on weaker steels. Thus if you ask the same question :

-At what angle do I need to sharpen 420J2 to have twice the edge retention as as 21 dps - 1000 grit WE edge on S110V cutting half inch plywood?

The answer might be that it is not possible as you can not reduce the angle on the 420J2 enough to compensate as it would be so low it would not have the strength to cut the plywood and would just deform.