Shouldn't you start a separate thread for serrated edges?Cliff Stamp wrote:As an update, I have done some more work with ultra-low grits, including 36-grit grind belts glued to wood :

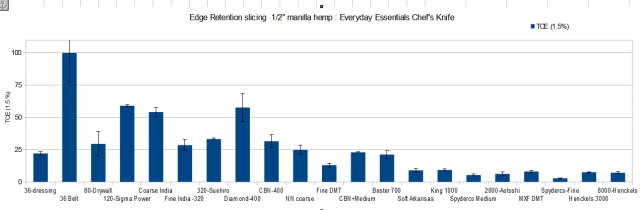

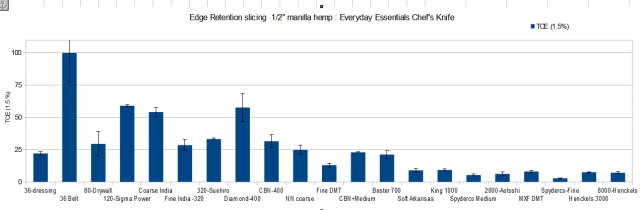

Edge retention as influenced by apex finishing grit

Re: Edge retention as influenced by apex finishing grit

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

That is actually a fairly valid concern and a pretty interesting comparison. This isn't the lowest grit either, it was just the most coarse I could find poking around. At some point the edge will get so coarse you will be able to see the actual structure. The main difference between this and a serrated edge is sharpening, this is really trivial and there is no concern about broken/damaged teeth. It is also really easy to convert to a high polish and back to this, not so easy to make a serrated edge behave like a plain one and then reverse it.JNewell wrote:

Shouldn't you start a separate thread for serrated edges?

I do have a concern / question about the same thing with ultra-high carbon+carbide steels. I have done 80/100 grit finishes before on 60+ D2 type steels, but not on 10V and MaxaMet type materials. It doesn't jump out to me though why they would fail to have a similar effect but I really need to run the numbers to know. I'll likely try it with the K2/Farid when I get some decent material to cut up.

Re: Edge retention as influenced by apex finishing grit

Would it be possible to combine high push cutting sharpness with high slicing sharpness? Say, if you had a very regular, yet large abrasive particles spread in a very regular square pattern and were using a jig to move the blade parallel to the line of particles, could you produce an edge which had aggressive, polished teeth? Or would the regularity of the scratch pattern be counterproductive in slicing edge retention? In a larger scale I've polished Spyderco serrations so that they push cut paper.Cliff Stamp wrote: Thus the reason the the Spyderco Medium rods give such a low slicing edge retention is simply because they produce a very high polish. It also has to be kept in mind that this list pretty much reverses if you look at push cutting edge retention. In fact the extremely coarse edges are so low performing there they can fail immediately if you try to push cut, but can cut for a very long time (>1000+ ) on a slice.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

Good question, Atoma plates are exactly like that. I'll have to see what I can do with one of them and see what I can get in terms of slicing and push cutting performance. I am thinking that a way to look at it simply is something likeMallus wrote:Say, if you had a very regular, yet large abrasive particles spread in a very regular square pattern and were using a jig to move the blade parallel to the line of particles, could you produce an edge which had aggressive, polished teeth?

metric = slicing edge retention * push cutting sharpness

Thus AEB-L would have a higher edge retention than 3Cr13 under this metric which means for a given slicing edge retention it would have higher push cutting sharpness and thus better push cutting ability and edge retention.

This metric is also very easy to measure, in fact the performance in terms of slicing edge retention is extremely well correlated to 1 / push cutting sharpness. It gets only slightly modified by the initial slicing sharpness. This means you can actually predict the results of those insanely long cutting trials with two initial sharpness measurements. Now if I could only figure out how to do that for steels similar to how I can do it for grits.

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: Edge retention as influenced by apex finishing grit

Well Cliff, once again I'm feeling completely stupid. I have been very curious about this issue though. Put simply, does a toothy edge apex or a smooth edge apex stay sharp longer? Keeping the question this simple would mean asking about one steel type and it cutting the same material. Not to mention the edge angles needing to be the same. I have always "assumed" a smooth edge would stay sharp longer only because the area between the teeth on a toothy (coarse) edge being filled with steel (making it smoother) would reinforce the steel that makes up the teeth. On a very toothy or coarse edge I've sort of "assumed" the teeth would snap off during use leaving the apex duller. In addition to this you've included different stone or abrasive types. I never considered that. A coarse diamond stone and a coarse water stone that would leave the same size "teeth" or scratch depth I'd consider the same. I don't understand anything other than the end condition of the blade steel and I don't understand that very well either. Not compared to someone with advanced knowledge.

Not having the education regarding steel nor the testing expertise I've been putting a smooth apex or leaving the edge toothy on a knife based on performance only. I'd think for instances where someone cuts the same thing all day (meat for example) you would use the best edge for CUTTING. If the best edge type for cutting is the one with poorer edge retention you would just live with it and touch up the edge more often. That might be better than using the knife that would stay sharp longer if the cutting performance made the work more difficult.

Thanks for the time and effort you put into your evaluation of all this stuff. I appreciate your effort even when I don't "get" a lot of what you say. Even with pictures (graphs and charts). :D

Jack

Not having the education regarding steel nor the testing expertise I've been putting a smooth apex or leaving the edge toothy on a knife based on performance only. I'd think for instances where someone cuts the same thing all day (meat for example) you would use the best edge for CUTTING. If the best edge type for cutting is the one with poorer edge retention you would just live with it and touch up the edge more often. That might be better than using the knife that would stay sharp longer if the cutting performance made the work more difficult.

Thanks for the time and effort you put into your evaluation of all this stuff. I appreciate your effort even when I don't "get" a lot of what you say. Even with pictures (graphs and charts). :D

Jack

Re: Edge retention as influenced by apex finishing grit

I see where you're going - that's very interesting.Cliff Stamp wrote:That is actually a fairly valid concern and a pretty interesting comparison. This isn't the lowest grit either, it was just the most coarse I could find poking around. At some point the edge will get so coarse you will be able to see the actual structure. The main difference between this and a serrated edge is sharpening, this is really trivial and there is no concern about broken/damaged teeth. It is also really easy to convert to a high polish and back to this, not so easy to make a serrated edge behave like a plain one and then reverse it.JNewell wrote:

Shouldn't you start a separate thread for serrated edges?

I do have a concern / question about the same thing with ultra-high carbon+carbide steels. I have done 80/100 grit finishes before on 60+ D2 type steels, but not on 10V and MaxaMet type materials. It doesn't jump out to me though why they would fail to have a similar effect but I really need to run the numbers to know. I'll likely try it with the K2/Farid when I get some decent material to cut up.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

In general, if you are slicing soft materials then a coarse finish will hold a low sharpness longer. If you are push cutting a hard material, then a higher grit finish will hold a high sharpness longer. If you go to extremes then the differences will be extremes.jackknifeh wrote:Put simply, does a toothy edge apex or a smooth edge apex stay sharp longer?

For example hemp is an extremely soft material and will not tend to deform or crack off the irregular finish of the coarse grit, thus what you see is mainly very slow wear and extremely coarse edges can last a long time cutting ropes and other soft materials.

This is a very valid point. Lets assume you had to for some reason cut 500 pieces of 1/2" hemp rope with a simple blade in 1050 carbon steel at 55 HRC would you :I'd think for instances where someone cuts the same thing all day (meat for example) you would use the best edge for CUTTING. If the best edge type for cutting is the one with poorer edge retention you would just live with it and touch up the edge more often. That might be better than using the knife that would stay sharp longer if the cutting performance made the work more difficult.

-sharpen the knife with 36 grit and do the cutting starting at < 10 lbs on a slice and ending at < 20 lbs on a slice without sharpening

or

-sharpen the knife with a fine DMT rod, do the cutting starting at <5 lbs, make 100 cuts, take a break, make a couple of passes on the DMT rod and then do another 100 passes, cutting force never exceeds 10 lbs

In the first example you made ~15 lbs pushes for 500 repetisions, so approximately 7500 lbs. In the second you made ~7.5 lbs pushes for 500 times so approximately 3750 lbs -and- you make about 10 passes on a DMT rod.

If you watch tradespeople who actually have to get work done, they don't do the first one, they don't use tools which have the ability to perform at a low standard for a high amount of time, they use ones which can work well and then maintain/replace as necessary.

I think it is interesting to explore aspects of steels, even in extremes, however for practical purposes there are other considerations. I don't choose which knives I will carry/use or sharpen them based on the ability to make a high hemp count, one of the reasons was the exact point you made.

At times I want the knife or finish which maintains a high sharpness and is optimized for cutting ability. Other times it might be one which is chosen for durability or ease of maintenance, or some combination of all of those.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

I am curious about a few things, like for example what happens if I take the 36-grit edge and do some very light work with a decent high grit sandpaper. Would it be possible to actually raise the sharpness as it were of the teeth or would I just end up with a just sort of more polished finish. These are interesting questions, but they are pretty non-trivial to answer. These ultra-coarse edges have extreme edge retention, I can even get them to stop slicing newsprint with ~2000 cuts. I just stop there as they are < 1.5% of optimal at that point. If I am doing five runs to check consistency that means 10, 000 cuts on 1/2" hemp. I buy rope by the actual full role but even then a trial like that cost ~$50, so if I check a few finishes it costs as much as a custom knife. Plus doing 50, 000+ cuts takes a little time. Hopefully I will get some used mooring line soon then I can run some trials on that, check it for consistency vs softer materials and then just use that. This is one of the real problems with a little knowledge of how angles/grits influence edge retention. It quickly gets to the point that you need scads of material to blunt them which also itself raises a few obvious questions.Mallus wrote:

... could you produce an edge which had aggressive, polished teeth?

Re: Edge retention as influenced by apex finishing grit

I wonder if fine grit sandpaper would conform to the crevasses or just knock off the tips that protrude the furthest? What about some stropping compound on a suitable substrate? I understand the problem of work and expenses related to generating data - maybe the used mooring line, dirty as it's likely to be, would dull the knives faster and help with the economics at the same time.Cliff Stamp wrote: I am curious about a few things, like for example what happens if I take the 36-grit edge and do some very light work with a decent high grit sandpaper. Would it be possible to actually raise the sharpness as it were of the teeth or would I just end up with a just sort of more polished finish. These are interesting questions, but they are pretty non-trivial to answer. These ultra-coarse edges have extreme edge retention, I can even get them to stop slicing newsprint with ~2000 cuts. I just stop there as they are < 1.5% of optimal at that point. If I am doing five runs to check consistency that means 10, 000 cuts on 1/2" hemp. I buy rope by the actual full role but even then a trial like that cost ~$50, so if I check a few finishes it costs as much as a custom knife. Plus doing 50, 000+ cuts takes a little time. Hopefully I will get some used mooring line soon then I can run some trials on that, check it for consistency vs softer materials and then just use that. This is one of the real problems with a little knowledge of how angles/grits influence edge retention. It quickly gets to the point that you need scads of material to blunt them which also itself raises a few obvious questions.

A further concern down the line I'd have is how my joints would feel after the +50k cuts exercise... Thank god for creating the Sasquatch so I don't have to do it! :)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

I just realized that I can do some sharpening experimenting, take pictures and record sharpness measurements a lot faster than doing the cut trials. It seems obvious in reflection that it might be worth while to look at a few over lays, see what tends to happen and do a select few trials. The behavior is also quite predictable as it follows the same equation every time, only the coefficients change, and thus even a short run of < 100 cuts can also be used to weed out various non-functional approaches. For example what are the properties of these finishes :Mallus wrote:

[...]

I wonder if fine grit sandpaper would conform to the crevasses or just knock off the tips that protrude the furthest? What about some stropping compound on a suitable substrate?

a) apex set with CBN rods and then, two passes with medium rods

b) apex set with CBN rods and then, ten passes with medium rods

c) apex set with CBN rods and then, two passes with fine rods

d) apex set with CBN rods and then, ten passes with fine rods

How do you think these would rank compared to :

-apex set with CBN rods

-apex set with medium rods

-apex set with fine rods

In regards to initial sharpness on both a slice and a push and edge retention on both?

Here is the real danger though, which is the base concern in all measurement - are you measuring something which is relevant to the question you are trying to answer. Used carpet for example is very abrasive and in general will dull a knife edge far faster than hemp rope (by more than an order of magnitude) but it also does it by a different (but related) mechanism. It isn't then at all correct to argue that since performance was see on used carpet then that can be used to predict performance on hemp, or cardboard or to jump from hemp/cardboard to foods - aside from some carefully made generalizations.I understand the problem of work and expenses related to generating data - maybe the used mooring line, dirty as it's likely to be, would dull the knives faster and help with the economics at the same time.

I have tried at times to look at the trades as that is an obvious huge source of information, but the problem is that it is widely scattered and damage tends to be dominant over anything else. I still keep track of it, but it is very hard to draw conclusions from it. Just try sharpening knives for friends, change techniques and see how it influences how long it takes them to ask you to sharpen again. I find that this time can be influenced with things not at all related to what you might expect. Still though, it can be useful to get some perspective from people who really don't care about sharpening/abrasives/steels any more than you likely care about the type of paper you use to write down a phone number.

Re: Edge retention as influenced by apex finishing grit

...which is not, I think, how knife enthusiasts tend to view edge retention - correct me if I'm wrong, please. This is a fascinating thread...back to slicing sweet potatoes, beans and turkey...Cliff Stamp wrote:

If you watch tradespeople who actually have to get work done, they don't do the first one, they don't use tools which have the ability to perform at a low standard for a high amount of time, they use ones which can work well and then maintain/replace as necessary.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

It really depends on who you talk to, there are basically two broad ways to look at it from an evaluation point of view, or just use point of view. There are people who want the knives to cut really well vs those that want to avoid sharpening for a long time. These two goals will produce two very different types of steels. Now to be clear, it isn't that either of those goals is right/wrong, a goal is subjective to the individual - the methods/materials however to achieve said goals are fundamentally not so unrestricted. If you want a stainless steel for example it restricts materials to specific grades, but the choice for you to want a stainless steel or not is essentially a free one.JNewell wrote:

...which is not, I think, how knife enthusiasts tend to view edge retention

A key figure metallurgy and knife maker wise on the cutting ability side is Roman Landes. If you read what Roman writes it is clear that his goals are very consistent in that he is talking about knives from the point of view of making a tool which cuts very well. From this perspective picking a steel which can basically stay blunt for a long time isn't overly useful because the cutting ability is very low at that point. For example lets say you compare a knife in D2 vs 1095 cutting cardboard and you let them get really dull, say down to 0.5% of optimal sharpness. This is cutting on the order of km's of cardboard. In this case the D2 blade will have an advantage over the 1095 because of the higher low stress abrasive wear resistance. But someone like Roman would look at that completely befuddled because no matter how you make it, a dull knife is doesn't cut as well (in general, on most materials) as a cheap knife which is kept sharp. The guy with the $1 knife made from 420J2 easily has a far easier time cutting if he makes just 1-2 passes on a sharpening rod every 100 cuts vs the guy with the MaxiMax steel who does 1000 cuts and refuses to sharpen.

But you can also look at it from the exact opposite point of view. Tom Mayo was fond of noting that he made knives for hunting guides who would return them once a year for sharpening, after the season. In that case what type of steel works well, the kind that stays blunt for a long time but can still cut. What kind of steel did Tom's clients really like - 440V, a massively high vanadium/chromium rich carbide steel. It takes that kind of steel a really long time to wear completely smooth and get to the point you really can't cut with it and it just slips/smashes.

Now you don't have to fall into either camp as it were, most people sort of are in between and in fact people who are semi-serious about tool choices will tend to vary depending on what they are doing. It is no different than going into a carpentry shop and seeing a selection of chisels. Some of them may be very high hardness/carbide steels like Blue/White, some of them may be much more basic carbon steels, some may even be A2 and D2 tool steels. A cold chisel, mortise chisel and paring chisel are likely to have very different steels. A big step in viewing steels (or abrasives) comes from when you switch from the viewpoint of "what is better" to "what is it better at" . This doesn't look to be a huge difference but it completely changes perspectives.

In most cases people do this automatically. If I asked a question here "What is a better kitchen knife, a bread knife or a paring knife?" Most people would be a bit puzzled, some would be amused and most of the answered would be similar to "Ah, well it would depend on if you were cutting a lot of bread or peeling a lot of potatoes? Are you working in a bakery or are you recently enrolled in the Army and your drill instructors is finding push ups are not working any more?" . But if I was to ask "What is a better steel, S90V or 420J2?" there is likely to be a completely different response, because the perspective there has changed from "what is it better at", but the same types of questions are still the most valid and meaningful "It depends, what kind of properties are you looking for in the knife?".

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

As a quick check on overlaying grits I finished an edge with the CBN rods and then did 5 pps with the medium rods. There was a marked improvement in sharpness on both the slice and the push cut - however the edge retention on a slice decreased by the same amount. As expected as the medium rod increases the polish the edge retention on a slice degrades for the exact same reason.

I only did two runs, I would want at least two more to even have light confidence but there is nothing unexpected about the result. It just moves the performance from the CBN towards the Medium rods. I suspect that as you do more passes it would simply move closer. However this does allow you to basically have "more" grits.

If you find the CBN too coarse and the Medium too fine then just apex on the CBN and do a few passes on the Medium to make an effective grit which is between them. A curious question would be if you used the fine rods would they make a larger difference or smaller one?

Note that the difference in performance in this graph from left to right is 50X, that is fifty times higher edge retention and this isn't even the limit of the performance. I think the 36 grit is a little low as I only used it a few times to sharpen so I don't have the technique down yet - plus to be frank once the cuts go over 1000 I tend to be a little sloppy so the performance is likely biased towards a lower number.

Plus of course I am not confident that 36 grit is actually the highest performance one, I am going to try some 24 grit (not really looking forward to that if it is better) as that is a common sharpening abrasive. I have seen very low grits but they tend to be used for grinding granite not steel and I suspect the abrasive crystals are a different shape to make them stronger but less sharp.

--

Note that if you click on the image it takes you to a page in PB where you can click on it to magnify it significantly.

I only did two runs, I would want at least two more to even have light confidence but there is nothing unexpected about the result. It just moves the performance from the CBN towards the Medium rods. I suspect that as you do more passes it would simply move closer. However this does allow you to basically have "more" grits.

If you find the CBN too coarse and the Medium too fine then just apex on the CBN and do a few passes on the Medium to make an effective grit which is between them. A curious question would be if you used the fine rods would they make a larger difference or smaller one?

Note that the difference in performance in this graph from left to right is 50X, that is fifty times higher edge retention and this isn't even the limit of the performance. I think the 36 grit is a little low as I only used it a few times to sharpen so I don't have the technique down yet - plus to be frank once the cuts go over 1000 I tend to be a little sloppy so the performance is likely biased towards a lower number.

Plus of course I am not confident that 36 grit is actually the highest performance one, I am going to try some 24 grit (not really looking forward to that if it is better) as that is a common sharpening abrasive. I have seen very low grits but they tend to be used for grinding granite not steel and I suspect the abrasive crystals are a different shape to make them stronger but less sharp.

--

Note that if you click on the image it takes you to a page in PB where you can click on it to magnify it significantly.

Re: Edge retention as influenced by apex finishing grit

Other than predicting the highest push cutting sharpness when the apex was set with the fine rods, I'd be hesitant to place bets. In a) to d) I guess you meant micro beveling as the jump in grids is so high the finer grids would probably not do much at the same apex angle with so few strokes? To get high push cutting sharpness I'd expect you'd need to be able to sharpen not only the tips of the coarse edge but also get into the valleys somehow, which is where the medium and fine rods will struggle, inflexible as they are, as long as you're not removing the coarseness altogether. In any case, I look forward to the results, should you test your new idea of faster data generation!Cliff Stamp wrote: I just realized that I can do some sharpening experimenting, take pictures and record sharpness measurements a lot faster than doing the cut trials. It seems obvious in reflection that it might be worth while to look at a few over lays, see what tends to happen and do a select few trials. The behavior is also quite predictable as it follows the same equation every time, only the coefficients change, and thus even a short run of < 100 cuts can also be used to weed out various non-functional approaches. For example what are the properties of these finishes :

a) apex set with CBN rods and then, two passes with medium rods

b) apex set with CBN rods and then, ten passes with medium rods

c) apex set with CBN rods and then, two passes with fine rods

d) apex set with CBN rods and then, ten passes with fine rods

How do you think these would rank compared to :

-apex set with CBN rods

-apex set with medium rods

-apex set with fine rods

In regards to initial sharpness on both a slice and a push and edge retention on both?

Yes, I have run into the same problem with many different experiments I've run - doing them the hard way is too hard / expensive / slow and cutting the corners will make circles out of squares. Sometimes it's still useful, even if you can only conclude that the height of the square, if it was a square to begin with, couldn't have been smaller the the diameter of the circle. :)Cliff Stamp wrote:Here is the real danger though, which is the base concern in all measurement - are you measuring something which is relevant to the question you are trying to answer. Used carpet for example is very abrasive and in general will dull a knife edge far faster than hemp rope (by more than an order of magnitude) but it also does it by a different (but related) mechanism. It isn't then at all correct to argue that since performance was see on used carpet then that can be used to predict performance on hemp, or cardboard or to jump from hemp/cardboard to foods - aside from some carefully made generalizations.

Cliff Stamp wrote:I have tried at times to look at the trades as that is an obvious huge source of information, but the problem is that it is widely scattered and damage tends to be dominant over anything else. I still keep track of it, but it is very hard to draw conclusions from it. Just try sharpening knives for friends, change techniques and see how it influences how long it takes them to ask you to sharpen again. I find that this time can be influenced with things not at all related to what you might expect. Still though, it can be useful to get some perspective from people who really don't care about sharpening/abrasives/steels any more than you likely care about the type of paper you use to write down a phone number.

I've sharpened knives to my friends, but since I don't have any jig system at the moment, I don't do too much of it. As it is, the knives when I first get them have extremely thick edges and are dull as can be. Thinning the edges requires coarse stones and freehanding with them, scratches are hard to avoid. My old mother, on the other hand, has cheap old kitchen knives that I experiment with. Despite my advices she keeps on cutting against metal and ceramics and therefore there's always work waiting for me whenever I visit her. Once the knives are properly thinned, it doesn't take too long to fix the edges. If she were to cut on cutting board only, I'd have much less practice so I'm happy she does things the way she wants. :)

Considering data generation, my in-laws, who also benefit from my sharpening services, are a funny story. A reflection of times past, they each have a small paring knife sized thing, decades old, they use in the table to piece bread, peel apples, spread butter, a wide variety of things. I had sharpened their knives numerous times but always wondered how on earth they get so dull so fast. Then one of them revealed that after my sharpening they scrape the edge with a nail to dull it... The thing is, if your hands are a bit shaky and you use the knife to cut tough rye bread against your own palms, it can be too sharp.

I like these lessons as they remind me that the optimum and maximum are not the same thing, and that I cannot always predict all even the most important variables beforehand, even if I try my best. Therefore, what is left is the iterative process and lot of repetitions. Easy grindability is a friend here :)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

I was wondering the same thing, they make a difference at the same apex angle very quickly. In retrospect I should have realized that they have to follow the exact same type of nonlinear behavior seen in edge dulling. I posted above what happens with CBN + 5 pps on the medium rods. I may look at the ultra-coarse edges the weekend as I am also going to try to find some grits below 36.Mallus wrote:

I guess you meant micro beveling as the jump in grids is so high the finer grids would probably not do much at the same apex angle with so few strokes?

I would think that they will both smear out and abrade the edges of the larger teeth, similar to if you just sharpened the back side of a serrated edge knife. It makes a dramatic difference on the CBN rods to even do just 5 pps, the push cutting sharpness increases by about 50%. Now to be clear I am working on a really easy to grind steel, 3Cr13.To get high push cutting sharpness I'd expect you'd need to be able to sharpen not only the tips of the coarse edge but also get into the valleys somehow ...

Experiments are often useful if only to conclude that experiment isn't the one that answers the question you want. There is an entire thread on T0.1M where I list all the experiments I do that don't tend to be directly productive for many reasons. But often times in order to figure out how to make a light bulb you have to figure out the ways not to make one.Sometimes it's still useful, even if you can only conclude that the height of the square, if it was a square to begin with, couldn't have been smaller the the diameter of the circle. :)

Ha, yeah depending on perspective.I like these lessons as they remind me that the optimum and maximum are not the same thing, and that I cannot always predict all even the most important variables beforehand, even if I try my best.

For the latter knives you referenced, one thing I have done which has had a measure of success is to set an edge similar to :

-20+ dps

-very coarse

-little work on a muddy stone

If people do not want very high sharpness then it is likely they are not interested in very high cutting ability and you can then exploit the high durability of large apex angles. A slightly more coarse edge will allow some measure of slicing ability and the muddy stone will keep the sharpness down as the mud slightly rounds all the sharp edges. This pre-blunting as it were changes the mechanism of blunting in use because you no longer get that early rapid decline which comes from the failure of very thin (sub micron) steel facets.

Now if most people read that then they would think that is a pretty horrible edge, and it is for people "into" sharpening. But for a lot of the people I sharpen knives for they don't want an edge so sharp it easily cuts you on contact. They are looking for a durable edge which takes a little effort to cut something but stays that way for a decent length of time. The properties here are very different and thus demand different angles/finishes and procedures to get optimal performance.

Steel is much the same.

A friend asked me recently if he should get a 440C or Japanese White steel knife, he didn't mind the corrosion. I asked to see one of the knives he was currently using, it was not damaged, but dulled far beyond the ability to slice newsprint well and he was still happy using it. Easy decision, get the 440C and if you really want to splurge, get an Elmax, S30V or S90V. A nice Japanese White steel blade isn't going to make a more optimal blade there unless he was radically going to change how he used his kitchen knives.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

From a practical perspective, a lot of the time these issues are moot. Here for example is some commentary on White steel chisels which is similar to a lot of work in knives praising high edge retention :jackknifeh wrote:

[...]If the best edge type for cutting is the one with poorer edge retention you would just live with it and touch up the edge more often. That might be better than using the knife that would stay sharp longer if the cutting performance made the work more difficult.

Here is a practical response to it from a guy who actually works professionally in the trade :"I'm building a small chest for a friend using some of the hardest, densest, gnarliest maple I've ever come across. It's like working a tropical exotic....

I purchased a 12mm Fujihiro bench chisel from Hida Tool a couple months ago. I chopped all the joints for this chest with this chisel. And I didn't go back to my stones once. That's right. The edge retention simply blew me away. That's about 5 running feet of continuous rock-hard, abrasive birdseye maple end grain work. And for fun I took some wispy thin end grain basswood shavings after I finished the last socket. Simply amazing."

Now how much time really are you going to spend thinking about something which has such a tiny effect? Rather than spend a significant amount of time/money on a chisel which may or many not have better edge retention, the same amount of time and money is likely to have far greater practical rewards if spent elsewhere. Hence the entire argument over "better" steels is often similar to two people arguing over what kind of salt to use to season steak. If the difference between one type of sea salt and another is actually going to be the deciding difference then you are in a fairly extreme end of the spectrum. No issues, but a little perspective is necessary here.If I am making a chest of drawers with 6 chests, with dovetails on the drawers, my experience is that my chisels should be able to chop all the dovetails for a drawer without resharpening. Suppose that I do have to resharpen my chisel between each drawer. That would be a total of 12-18 minutes at most of sharpening time spent on this project. (More likely, it would be less as I probably would only have to do the 30 second honing.) If I had a chisel with better edge retention that could take me through all 6 drawers without resharpening, I'll save that 12-18 minutes. I have no idea how long it should take to make a chest of drawers, but if it takes 60 hours, that works out to a 0.5% increase in efficiency.

In knives, Jerry Fisk is one of the few knifemakers who is vocal about that and about how edge retention isn't as critical as often promoted. This is a guy who obviously can make knives out of any steel he wants and harden them any way you could want, but yet on his personal knives he can and does use simple steels and :

"I personally prefer a softer draw on my knives for several reasons. On my personal knife I draw the temper back to about a 52. I like the more aggressive edge and it holds for me longer. It is also tougher and will take more abuse. When I go off hunting for a week at a time I do not want to carry a bunch of stones to sharpen it with nor do I want to worry about what ever I put it through. This just holds up better in the way I personally use a knife. I sure would not have to worry about stresses from bends. To me toughness is more important than hardness."

This of course is very similar to the steel and type of hardening in Opinels, Normark folders, Herder kitchen knives and the list goes on.

Re: Edge retention as influenced by apex finishing grit

Thanks for the tip! I'll give it a try the next time I sharpen their knives. I only have one water stone (a combo Cerax 1000/6000), which is perhaps a little fine for a coarse edge, but if I raise a thick slurry and use it only a little in the final stage after a coarse DMT (or coarser, I have almost all the grids from XXC upwards), it might still be usefull.Cliff Stamp wrote:For the latter knives you referenced, one thing I have done which has had a measure of success is to set an edge similar to :

-20+ dps

-very coarse

-little work on a muddy stone

If people do not want very high sharpness then it is likely they are not interested in very high cutting ability and you can then exploit the high durability of large apex angles. A slightly more coarse edge will allow some measure of slicing ability and the muddy stone will keep the sharpness down as the mud slightly rounds all the sharp edges. This pre-blunting as it were changes the mechanism of blunting in use because you no longer get that early rapid decline which comes from the failure of very thin (sub micron) steel facets.

Now if most people read that then they would think that is a pretty horrible edge, and it is for people "into" sharpening. But for a lot of the people I sharpen knives for they don't want an edge so sharp it easily cuts you on contact. They are looking for a durable edge which takes a little effort to cut something but stays that way for a decent length of time. The properties here are very different and thus demand different angles/finishes and procedures to get optimal performance.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

Find a jewler or someone in an auto body shop or anyone who does sandblasting, go to their shop and say something clever like "Look over there!" and take a handful of low grit loose silicon carbide. It only takes a tiny amount on a stone (as in a mound which is 2-3 mm in diameter) to produce some very harsh scratch patterns in an edge.Mallus wrote:

I only have one water stone (a combo Cerax 1000/6000)...

If you put that on the stone when you are in the middle of setting the edge and then let the mud build up you will end up with an edge very similar to what I described, a kind of muddled semi-coarse, semi-sharp edge which will stay that way for a long time. Plus when someone asks you about it you can say something like this to impress them :

"The edge is created using a non-homogeneous semi-suspension to produce a bi-directional scratch gradient which diverges from the standard nonlinear performance loss due to being able to generate adequate rupture pressures on contact for extended high cycle applications."

Re: Edge retention as influenced by apex finishing grit

Dang, but I don't even have to sandbag anybody for her sand - I already have an unused bottle of 180 grit silicon carbide! Not too coarse, unfortunately, but still it's coarser than my waterstone. Now, before I set about making my own mud, would you advice me to use the Cerax or a diamond plate as a substrate? I could try, of course, but I've loaned my coarsest (XXC) DMT plate to my cousin, who's not living very close to my place, and at the other end, it would be nice to be freed of the concern of imbedding the water stone semi-permanently with the semi-suspendable semi-coarse grit.Cliff Stamp wrote:Find a jewler or someone in an auto body shop or anyone who does sandblasting, go to their shop and say something clever like "Look over there!" and take a handful of low grit loose silicon carbide. It only takes a tiny amount on a stone (as in a mound which is 2-3 mm in diameter) to produce some very harsh scratch patterns in an edge.Mallus wrote:

I only have one water stone (a combo Cerax 1000/6000)...

If you put that on the stone when you are in the middle of setting the edge and then let the mud build up you will end up with an edge very similar to what I described, a kind of muddled semi-coarse, semi-sharp edge which will stay that way for a long time. Plus when someone asks you about it you can say something like this to impress them :

"The edge is created using a non-homogeneous semi-suspension to produce a bi-directional scratch gradient which diverges from the standard nonlinear performance loss due to being able to generate adequate rupture pressures on contact for extended high cycle applications."

Without trying, I wonder if the effectiveness of the SiC grit will be less in the XXC diamond plate, what with the heavy particles falling out of the suspension and into the valleys of the plate? Now the idea starts to interest me so much I may have to give it a go just to see what happens! I could start with a dotted XC DMT, even if the dots are kinda counterproductive for the purpose, or a continuous coarse DMT, both of which would be available unlike the XXC. :)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Edge retention as influenced by apex finishing grit

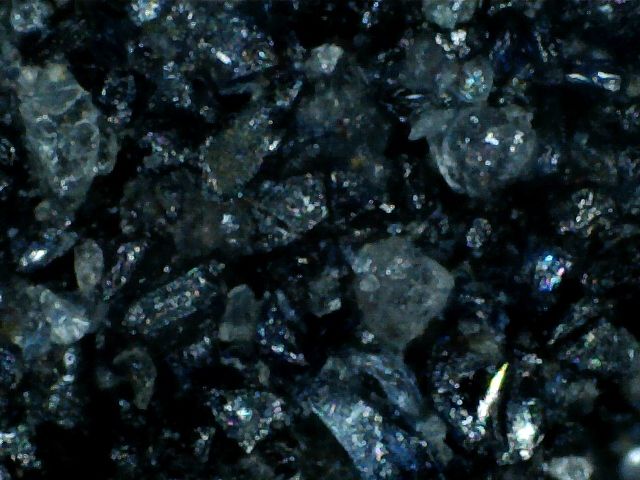

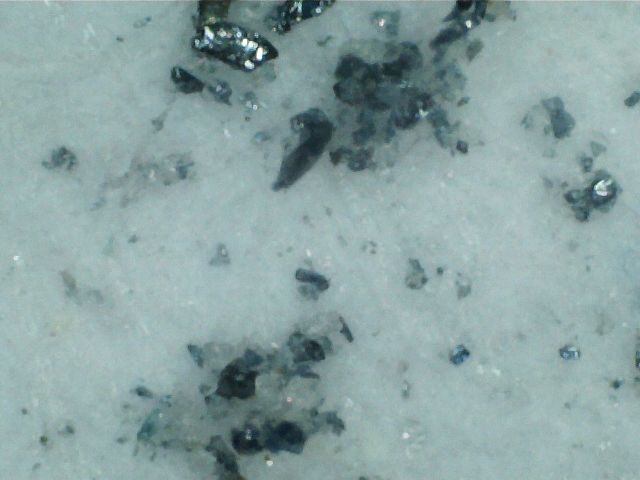

I think that is likely to make the finish finer than the XXC plate depending on the steel you are sharpening. Silicon carbide is an interesting sharpening abrasive as it is harder than aluminum oxide (slightly) but tends to be more friable (especially compared to the red/dark aluminum oxide) and thus it breaks down very fast. Just get some very coarse silicon carbide, say 36 grit, and put it on a stone and work it a little bit and then flush it with water and see just how fast the grits are crushed into a much finer paste. Just look at this :Mallus wrote:... I wonder if the effectiveness of the SiC grit will be less in the XXC diamond plate...

which is an xx-coarse silicon carbide stone. Compared to this :

Which is some of the slurry off that stone rinsed and put on blotter paper. There are still huge grits but a lot of very fine ones as well. The extreme friability of that abrasive is very nice in some respects, pretty bad in others depending on how you try to use it. It is a pretty horrible lapping abrasive for most stones because of the friability, despite it being commonly recommended. Aluminum oxide (brown) is a much better choice. But once you have the surface of the stone flat, then ideally you want to switch to silicon carbide again to recut the surface as aluminum oxide will tend to blunt the stone (unless it is a quartz stone).

Of course if you have lots of money just use diamonds as a lapping abrasive or CBN if you want to be fancy as cubic boron nitride is way cooler to say than diamond if anyone asks what you are doing.