Best steels/knives for...

- Doc Dan

- Member

- Posts: 14830

- Joined: Thu Nov 08, 2012 4:25 am

- Location: In a dimension as vast as space and as timeless as infinity.

Re: Best steels/knives for...

So, kind of like a glass knife or diamond knife used in electron microscopy?

I Pray Heaven to Bestow The Best of Blessing on THIS HOUSE, and on ALL that shall hereafter Inhabit it. May none but Honest and Wise Men ever rule under This Roof! (John Adams regarding the White House)

Follow the Christ, the King,

Live pure, speak true, right wrong, follow the King--

Else, wherefore born?" (Tennyson)

NRA Life Member

Spydernation 0050

Follow the Christ, the King,

Live pure, speak true, right wrong, follow the King--

Else, wherefore born?" (Tennyson)

NRA Life Member

Spydernation 0050

-

yablanowitz

- Member

- Posts: 6909

- Joined: Sun Apr 09, 2006 2:16 pm

- Location: Liberal, Kansas

Re: Best steels/knives for...

They did release the Endura and Delica in G-10 a few years back. They didn't sell well enough to keep in the lineup, much less to move up to full production.elena86 wrote:What confuses me is why don't they release the Delica/Endura line in G10 or CF ? I would kill for a CF Delica in any steel with the new improved lock-back. This is a mistery for me :confused:

Re: Best steels/knives for...

Thanks Rick. My used Edge Pro came with the diamond stones as well as some glass blanks and various tapes, including the diamond tapes. I had been saving them for a ceramic kitchen knife I have, but it looks like it makes sense to try it out on S110V as well.Tall Dark and Swarfy wrote:2channel <> I have used 3M diamond lapping films mounted on EP glass blanks and had superb results. Quite inexpensive to dip your toe versus buying new mounted stones. PM me if you want to know more.

Cheers,

Rick

Re: Best steels/knives for...

Thanks again Cliff and Ankerson. I clearly need to work on my sharpening skills with S110V.

I had a few additional questions. I get Ankerson's point that the smaller the apex, the sharper the blade as well as Cliff's definitions.

I'd like to use the second definition Cliff listed, as it makes the most sense to me as an objective measure.

1. If two identical blades have the same apex width, but one blade is 10 dps and the other is 20 dps, would the 10 dps produce the deeper cut with a given force?

2. Will a steel with coarser grain (like S110V) have more potential issues with edge retention when taken to a low dps and small apex as compared to a finer grain steel (like ZDP-189)?

I'm willing to sacrifice ease of sharpening. From a practical perspective, it's something most people probably wouldn't/shouldn't do. But I view working with more difficult steels as part of the challenge and learning process. I went ahead and ordered an SPSII in 240 grit to try out.

I'll add Elmax to my list of steels to get around to trying in the future.

I had a few additional questions. I get Ankerson's point that the smaller the apex, the sharper the blade as well as Cliff's definitions.

I'd like to use the second definition Cliff listed, as it makes the most sense to me as an objective measure.

Using that definition, I have two additional questions.-the cut depth under a given force

1. If two identical blades have the same apex width, but one blade is 10 dps and the other is 20 dps, would the 10 dps produce the deeper cut with a given force?

2. Will a steel with coarser grain (like S110V) have more potential issues with edge retention when taken to a low dps and small apex as compared to a finer grain steel (like ZDP-189)?

I'm willing to sacrifice ease of sharpening. From a practical perspective, it's something most people probably wouldn't/shouldn't do. But I view working with more difficult steels as part of the challenge and learning process. I went ahead and ordered an SPSII in 240 grit to try out.

I'll add Elmax to my list of steels to get around to trying in the future.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Best steels/knives for...

Jim,Ankerson wrote:

The smaller (thinner) the apex width is in nano-meters the sharper the edge will be.

As I stated, you are define terms any way you want, the reason that it isn't defined that way in ISO and in the literature is because it produces a non-sensible definition of sharpness .

For example, take two blades which are identical in geometry and use them to slice 1/2" manilla rope :

-Blade A - takes 10 lbs on a 2" draw

-Blade B - takes 15 lbs on a 2" draw

Which one is sharper? Again these are the exact same geometrically, the only difference is in the nature of the apex. Which one is sharper?

Most people will automatically say A. However the definition that you give for sharpness can lead to Blade B being measured to be sharper which is why that isn't the definition used in the literature.

However if you define sharpness as the ability to produce rupture pressure, which is how it is defined in the literature typically, then Blade A is the sharper blade.

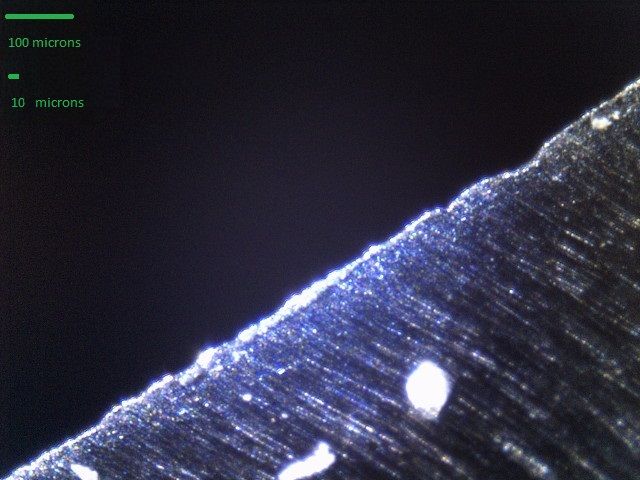

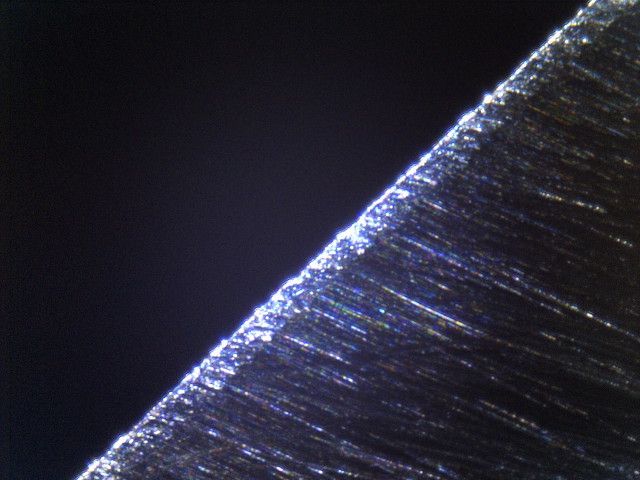

In pictures :

vs

These two knives have the exact same edge angle and apex angle and have both cut an equal amount of material. Now you want to determine the sharpness to see which has the better edge retention.

If you simply measure the apex width then the first one is thicker, thus it is not as sharp. However if you actually use both knives to slice something then the second one does better it cuts more under less force.

Hence again why looking at the apex width only isn't a sufficient definition for sharpness hence why it will be defined either in terms of rupture pressure or cut length as a function of load.

Re: Best steels/knives for...

For hard use knives apart from jobs involving only slicing of clean material, the flavor of the month steel thing may sell knives but gives the buyer very little.

Most wondersteels have shown to be able to chip or break far easier than many more common steels as any edge flex tests will show.

Pry up on a spinning screw with loose nut on backside in a quite common job task of a work knife while applying air power to tool with other hand to back out screw, and most wunderstahls will show themselves woefully inadequate even to old G2/AUS8A...

Sure, folk who have white collar jobs will scream bloody murder of a knife but normally nothing a quick touch up will not fix, and what other tool is out there with a fine edge and handle at 90° to radius and commonly with a.worker when he needs to get a job done?

Academic cuttings tests with too many variables to be academic are useless, whether production lot of of knives or media or operator variables disguised behind scientific sounding gobbledygook, are no help, and actual use is the only true criteria for judging a knife...

And that use shows me most worry about steels is simply an excuse to sell or buy a new flavor and that many so called advanced products do not do as well in real world as plainer boring ho-hum standbys....

Most wondersteels have shown to be able to chip or break far easier than many more common steels as any edge flex tests will show.

Pry up on a spinning screw with loose nut on backside in a quite common job task of a work knife while applying air power to tool with other hand to back out screw, and most wunderstahls will show themselves woefully inadequate even to old G2/AUS8A...

Sure, folk who have white collar jobs will scream bloody murder of a knife but normally nothing a quick touch up will not fix, and what other tool is out there with a fine edge and handle at 90° to radius and commonly with a.worker when he needs to get a job done?

Academic cuttings tests with too many variables to be academic are useless, whether production lot of of knives or media or operator variables disguised behind scientific sounding gobbledygook, are no help, and actual use is the only true criteria for judging a knife...

And that use shows me most worry about steels is simply an excuse to sell or buy a new flavor and that many so called advanced products do not do as well in real world as plainer boring ho-hum standbys....

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Best steels/knives for...

I don't think it is fair to group all of promotion of steels under the group as being fragile. There are lots of knife makers who when evaluating steels have durability as a part of what they do. For example, Joe Calton, Kyley Harris, Dan Keffler, Jeremy McCullen and many others who use many modern steels appreciate and design durability and rougher work as part of the critical aspects of the design.mtngunr wrote: Most wondersteels have shown to be able to chip or break far easier than many more common steels as any edge flex tests will show.

Now yes, there are many that focus on just very light work, and a total focus on just that can end up with steels which have low durability, it isn't accurate to say that all modern-duper steels have that property. As just one example, 3V is a modern PM steel which isn't brittle and has chip resistance as part of its intentional design.

Re: Best steels/knives for...

Go off-roading in a Porsche and see how that works out for you. Does that make the Porsche inadequate, or are you just misusing a high performance tool optimized for a different task?mtngunr wrote:Pry up on a spinning screw with loose nut on backside in a quite common job task of a work knife while applying air power to tool with other hand to back out screw, and most wunderstahls will show themselves woefully inadequate even to old G2/AUS8A...

I drink my bourbon out of an antique hand-cut crystal rocks glass that was given to me for my wedding. I can't drop it on the floor like my plastic party cup, but it's darn sure more enjoyable to drink from.

Re: Best steels/knives for...

Many or most have turned out to be exactly that.....a quick read of this forum or any other will show that to be true when used hard in real world.....but i give them this, maybe one day they will succeed.....but hiding behind Charpy notch numbers on a bar of steel which bears zero resemblance to a knife taken to a fine edge is no guarantee it works as a knife....only use will tell so long as makers just put it out there for consumers clamoring for latest steel, rather than test first before marketing.....and most have turned out to be nothing but higher priced hype....and custom makers unless somebody in ABS pushing the forging envelope for fun are just as guilty of pushing latest rave steel to sell knives....look at how market quickly took latest shocking results by master forging artists with 52100B and 5160 and used barstock for production knives due to public paying only attention to latest rave steel NAME rather than the forging and multiple thermal cycles behind it......most factories and custom folk simply follow the recipe in the book for barstock....period....and what you end up with often is as boring as a book as well....but not tellable by all the hype and fanboyism surrounding it.....and then same company and same fans then move on to latest flavor of the month....ill educated consumer demand driving it all...

Re: Best steels/knives for...

Carriage return.

- Surfingringo

- Member

- Posts: 5824

- Joined: Sun Sep 01, 2013 2:02 pm

- Location: Costa Rica

Re: Best steels/knives for...

I can put an edge to my thumb and get a fair approximation of the width of the apex (as well as how refined it is). That is what I call sharpness. Nothing else. I have heard a few argue that it is something else but I disagree. Most people disagree. Not sure what the books say but if I am in error about my definition then I am going to remain that way.Cliff Stamp wrote:Jim,Ankerson wrote:

The smaller (thinner) the apex width is in nano-meters the sharper the edge will be.

As I stated, you are define terms any way you want, the reason that it isn't defined that way in ISO and in the literature is because it produces a non-sensible definition of sharpness .

Re: Best steels/knives for...

Decafe try it. You don't have to buy new steels no one is forcing you. Plenty of makers both production and custom including ABS MS and JS are using 1095 1080 w2 etc if that's what floats your boat. You can buy a spyderco in I M4 which is a great carbon steel. I had a D2 by Dozier who is the master of heat treating D2 it will not hold a candle to my Para 2 in elmax in edge retention or toughness.And I don't say this lightly I loved that knife truly. I have used each on construction sites and the Para 2 flat out performs the best D2 on the market. I would say you might want to use a small scraper or even a mini pry bar for your bolts it gives better upward pressure on the bolt and the V of the pry keeps it in one place when spinning. Or just use the spine not the edge of your knife.Right tool for the job dad taught me that one. Unless your life is on the line there is no need for the one tool option.mtngunr wrote:Many or most have turned out to be exactly that.....a quick read of this forum or any other will show that to be true when used hard in real world.....but i give them this, maybe one day they will succeed.....but hiding behind Charpy notch numbers on a bar of steel which bears zero resemblance to a knife taken to a fine edge is no guarantee it works as a knife....only use will tell so long as makers just put it out there for consumers clamoring for latest steel, rather than test first before marketing.....and most have turned out to be nothing but higher priced hype....and custom makers unless somebody in ABS pushing the forging envelope for fun are just as guilty of pushing latest rave steel to sell knives....look at how market quickly took latest shocking results by master forging artists with 52100B and 5160 and used barstock for production knives due to public paying only attention to latest rave steel NAME rather than the forging and multiple thermal cycles behind it......most factories and custom folk simply follow the recipe in the book for barstock....period....and what you end up with often is as boring as a book as well....but not tellable by all the hype and fanboyism surrounding it.....and then same company and same fans then move on to latest flavor of the month....ill educated consumer demand driving it all...

We are not all looking for the same thing you are in a knife.Some of us are looking for pure edge retention others for pure toughness and yet others for a good mix of both. Not to mention levels of corrosion resistants and just plane old style. It's not always just about how you use it or what you like!

Re: Best steels/knives for...

My educated thumb tells me a lot too. :)Surfingringo wrote:I can put an edge to my thumb and get a fair approximation of the width of the apex (as well as how refined it is). That is what I call sharpness. Nothing else. I have heard a few argue that it is something else but I disagree. Most people disagree. Not sure what the books say but if I am in error about my definition then I am going to remain that way.Cliff Stamp wrote:Jim,Ankerson wrote:

The smaller (thinner) the apex width is in nano-meters the sharper the edge will be.

As I stated, you are define terms any way you want, the reason that it isn't defined that way in ISO and in the literature is because it produces a non-sensible definition of sharpness .

Re: Best steels/knives for...

Just look at the people on here and there uses for there knives. Surfingringo is around saltwater a lot and cleans a lot of fish. Ankerson Hates 5/8" manila rope with a passion and has vowed to chop it all up 1 inch at a time using every steel and knife he can get his hands on. Also I think he grows tomatoes. Cliff is an edge voyeur and likes to takes close up pictures and post them. I am smarty pants who thinks life is to short to be so serious. Different strokes (or Steel) for different folks. Each steel is like a tool with different uses the thing I like best about Spyderco is that I get to try them out and see what works best for my applications. Don't look at it as a way to hype steel but as a way for you to do the same as me and find the one that best suites you.

Last edited by Mic1 on Fri Jul 31, 2015 4:45 pm, edited 1 time in total.

Re: Best steels/knives for...

Mic1 wrote:Just look at the people on here and there uses for there knives. Surfingringo is around saltwater a lot and cleans a lot of fish. Ankerson Hates 5/8" manila rope with a passion and has vowed to chop it all up an inch at a time using every steel and knife he can get his hands on. Also I think he grows tomatoes. Cliff is an edge voyeur and likes to takes close up pictures and post them. I am smarty pants who thinks life is to short to be so serious.

In my old job I used to cut a ton of cardboard, pallet straps, shrink wrap and assorted other things.

I used my knives a lot in my job.

Re: Best steels/knives for...

Ankerson wrote:Mic1 wrote:Just look at the people on here and there uses for there knives. Surfingringo is around saltwater a lot and cleans a lot of fish. Ankerson Hates 5/8" manila rope with a passion and has vowed to chop it all up an inch at a time using every steel and knife he can get his hands on. Also I think he grows tomatoes. Cliff is an edge voyeur and likes to takes close up pictures and post them. I am smarty pants who thinks life is to short to be so serious.

In my old job I used to cut a ton of cardboard, pallet straps, shrink wrap and assorted other things.

I used my knives a lot in my job.

I seriously thank all of you for your input. Gringo, Cliff and Ankerson. In just the short time I have been in here I have learned a lot. I used windex last night when sharpening on my DMT and was thinking where had windex been all my life. Thanks to a post By you Ankerson I now have a sharper knife. And I love the knife steel chart I have it saved as a favorite. Did you ever do one for carbon steels?

Re: Best steels/knives for...

Glad I was able to help. :) :cool:Mic1 wrote:Ankerson wrote:Mic1 wrote:Just look at the people on here and there uses for there knives. Surfingringo is around saltwater a lot and cleans a lot of fish. Ankerson Hates 5/8" manila rope with a passion and has vowed to chop it all up an inch at a time using every steel and knife he can get his hands on. Also I think he grows tomatoes. Cliff is an edge voyeur and likes to takes close up pictures and post them. I am smarty pants who thinks life is to short to be so serious.

In my old job I used to cut a ton of cardboard, pallet straps, shrink wrap and assorted other things.

I used my knives a lot in my job.

I seriously thank all of you for your input. Gringo, Cliff and Ankerson. In just the short time I have been in here I have learned a lot. I used windex last night when sharpening on my DMT and was thinking where had windex been all my life. Thanks to a post By you Ankerson I now have a sharper knife. And I love the knife steel chart I have it saved as a favorite. Did you ever do one for carbon steels?

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Best steels/knives for...

There is no such thing as a right/wrong definition, when you define a word you are just telling me what you mean by it. If you use different definitions than a known language it isn't wrong, you just are not speaking that language.Surfingringo wrote: That is what I call sharpness.

If you define sharpness by the apex width then as noted in the above you are defining sharpness in a way that can allow a knife which is sharper to have lower cutting performance, you have just defined sharpness in a way that isn't connected to cutting ability.

Of course you can do that, it isn't wrong, it just doesn't make any sense. For example how could you speak about edge retention then, how are you determining that if sharpness isn't determined by cutting ability?

Again this is why the terms are defined the way I noted in the above. Just like all materials terms (strength, toughness, ductility) you could also create your own definitions and essentially be speaking some language you have created.

In the same way I can say that Lynn Thompson owns Spyderco as I simply define Spyderco to be the knife company that Lynn Thompson owns. This isn't inherently wrong, it just isn't overly sensible if your goal it to communicate with other people.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Best steels/knives for...

For example here are just a few of the recently introduced steels which are not inherently brittle :mtngunr wrote:Many or most have turned out to be exactly that.

-14C28N

-Nitrobe 77

-H1

Nitrobe 77 is one of the more high-tech/fancy/modern steels :

-powder metallurgy

-high nitrogen

-stainless steel

-high hardness

But yet it is very tough/durable, chip resistance is one of its highest attributes along with the corrosion resistance.

Or for example CruForge V was a new steel, just recently developed to be used for forging specifically for knives. Again it not an inherently brittle steel.

Not every knife maker / manufacturer ignores toughness as a functional concern.

- Surfingringo

- Member

- Posts: 5824

- Joined: Sun Sep 01, 2013 2:02 pm

- Location: Costa Rica

Re: Best steels/knives for...

Lol, of course it makes sense Cliff. It just doesn't make sense to you because you are looking at it in a different way. To me, your definition of sharp doesn't make any sense. If you compare an axe that will whittle hair to a piece of unsharpened roofing tin then the tin will do a better job of slicing cheese. Is it sharper? Try pulling those two edges across your skin and then tell me which one isn't sharp.Cliff Stamp wrote:There is no such thing as a right/wrong definition, when you define a word you are just telling me what you mean by it. If you use different definitions than a known language it isn't wrong, you just are not speaking that language.Surfingringo wrote: That is what I call sharpness.

If you define sharpness by the apex width then as noted in the above you are defining sharpness in a way that can allow a knife which is sharper to have lower cutting performance, you have just defined sharpness in a way that isn't connected to cutting ability.

Of course you can do that, it isn't wrong, it just doesn't make any sense. For example how could you speak about edge retention then, how are you determining that if sharpness isn't determined by cutting ability?

Again this is why the terms are defined the way I noted in the above. Just like all materials terms (strength, toughness, ductility) you could also create your own definitions and essentially be speaking some language you have created.

In the same way I can say that Lynn Thompson owns Spyderco as I simply define Spyderco to be the knife company that Lynn Thompson owns. This isn't inherently wrong, it just isn't overly sensible if your goal it to communicate with other people.

Last edited by Surfingringo on Fri Jul 31, 2015 5:09 pm, edited 1 time in total.