Interesting knife, I am still of two minds on the handle. I understand how / why Perrin has designed it, but there are some ergonomic issues in extended use. I can appreciate the stability in hand, even with an open grip which is one of the main aspects of the design, but the handle is a little squarish/boxy. In extended used, while breaking down some boxes for ease of reuse/recycling the handle just feels ill fitting. It just doesn't sit well in the hand comfort wise. But again the stability of working with an open grip is nice.

The edge thickness is a little high for this knife unless it was intended for pretty extreme contacts. The previous user brought the edge angle down to ~10 dps to increase the cutting ability but this leaves a fairly wide bevel which decreases ease of sharpening. It is only a simple modification to flatten the blade bevel however the owner doesn't want that done at this time, hence it is being used as is for now.

An interesting thing came up when I was cutting the cardboard as I noted the performance of the Street Beat was fairly low. I estimate, even without measurement that it was cutting maybe 1/5 to 1/10 the cardboard I would expect on average. However there are two explanations for this :

-this VG-10 is problematic

-this cardboard is extremely harsh on an edge

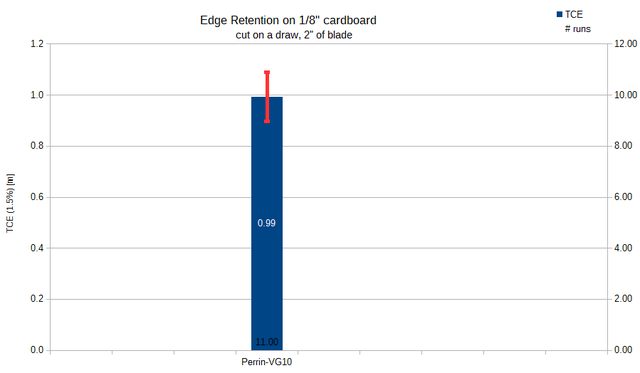

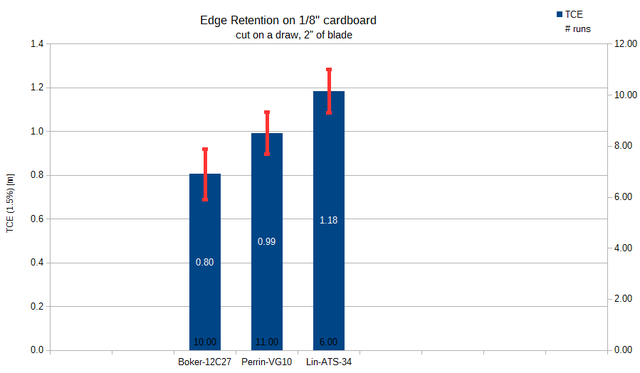

The cardboard was soft, but fairly abrasive, really scratched up a blade and was very dusty. It seemed likely to me that the cardboard itself could be the issue. I did a little work to see if this was the case or was it the steel itself. I did a standard edge retention measurement. The apex was set with a 600 DMT fine stone at 15 dps. The edge was reset with a Suehiro 'Chemical' 320 stone using plateau sharpening. The TCE was calculated as the measure of edge retention with the stopping point set to be ~1.5% of optimal sharpness. This is beyond shaving. It won't push cut any papers and will start to tear and make ragged cuts on newsprint.

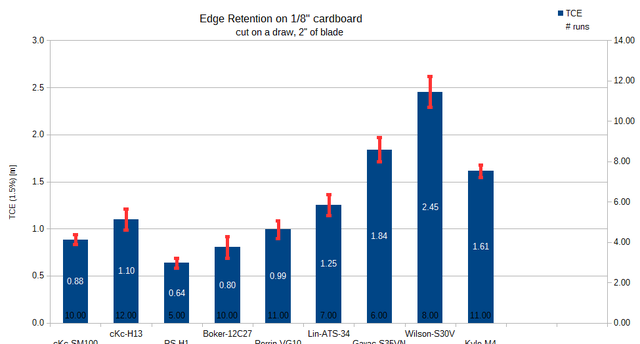

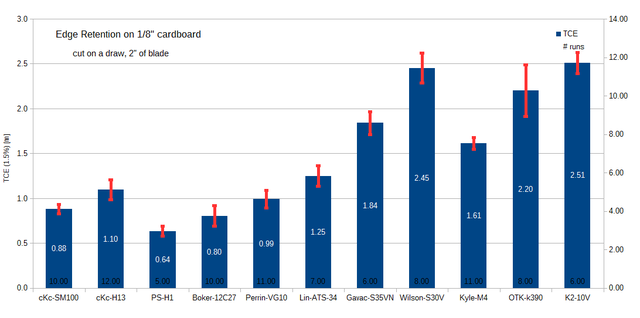

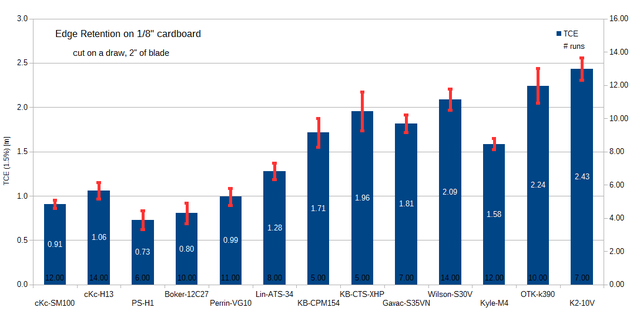

The results :

Legend :

-blue columns represent the edge retention

-the red bars are the error/uncertainty in the results (it is a weighted standard error)

-the white numbers are the TCE results (the column heights)

-the black numbers are the amount of runs done with each

Now from past experience this is a very low score. But I already knew that it would be low because of how fast the cardboard was taking down the edge. It doesn't tell me if it is the cardboard or the knife. The number also doesn't give very much information to anyone else though because unless you have done the exact same work that number won't mean anything obviously. In order to know if it was the knife or the cardboard I added a couple of other knives for a relative comparison. Nothing too surprising, it was a little better than a 12C27 blade (~10 dps edge) and a little behind an ATS-34 blade (~6-8 dps edge). In short the knife is fine, the cardboard is just really harsh to cut.

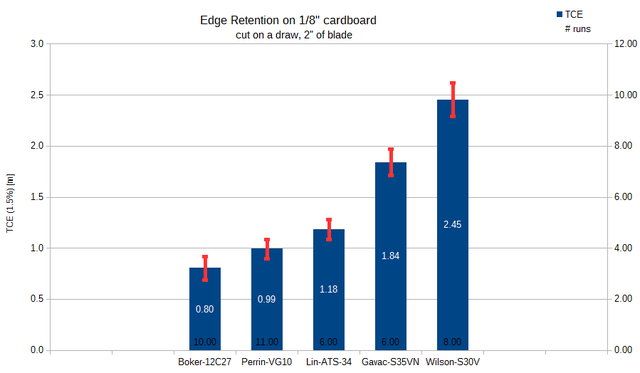

I had some cardboard left so I added a couple of other knives. A S35VN folder from Mike Gavac and a S30V fixed blade from Phil Wilson (both had ~6-8 dps edges). Again, nothing that surprising, the extra wear resistance from the vanadium carbides was enhancing the performance as would be expected and it also seemed that there was an increased hardness. The hardness was deduced from the fact that after the cutting there was less light reflecting from the edge and under magnification there appeared to be less rolling/impacting :

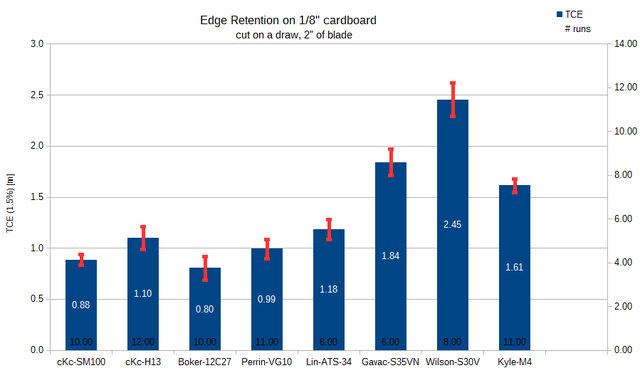

I still had some cardboard left and this is where it gets interesting. Now I have a pretty decent reference point of a bunch of blades so I can bring in some "unknown" blades/steels and use the existing work as a point of comparison. I used three interesting blades :

-SM100 mule, promoted as an extreme material, I have not had great results with it

-H13, very curious blade material

-M4, Peters, ~63 HRC, but I have had only ok/moderate results with it in the past

Using the existing data I can draw some conclusions :

-the M4 blade appears to have a problem as it should be doing better

-the SM100 blade is consistent with past experiences, it is moderate at best

I spoke to the maker of the M4 blade and it was preground very thin before hardening. This likely could have caused issues with the hardening such as over heating during the soaking or possible micro-cracking in the quenching. I have a few other M4 blades which I can run as points of reference/comparison.

The real interesting thing is the H13 blade. This is ~56 HRC, a fairly low carbide steel but a very high martensite percentage, less than 5% retained austenite as it is hot tempered. The curious thing isn't the average performance but the individual runs. The data tended to be similar to :

-0.5, 2, 0.45, 1.75

When averaged it was ~1 but the scatter was wide. Why did it behave that way? Looking at the apex under 50X magnification then it was seen that what happened on the very high performance runs was that the apex chipped / damaged in a way which produced high slicing aggression (which was the sharpness being measured). If this didn't happen, which is pretty random, then the low hardness and wear resistance produced fairly low performance, ~ 1/2 of VG-10. But when the edge broken down and produced that ragged apex then the sharpness was maintained at a high amount until all those little chips wore down.

I have a few other Spyderco blades to add, at least one, the K2/10V. It depends on how much longer the cardboard holds out.

--

In short :

-issues with edge retention can be the material rather than the blade

-the Street Beat in VG-10 is a solid example of VG-10

-dusty/dirty cardboard can be extremely harsh on an edge

-cardboard ranges massively in influence, a factor of 10 is not unlikely

-having known reference blades really helps pin down reliable conclusions

A few other notes on the blade :

-really nice/practical jimping, not overly abrasive but high traction

-the sheath is so loose it is a functional issue, the knife will actually fall out

-useful size/shape

-interesting approach to security in hand from Perrid with the no-guard guard