which steel do you think would be best

which steel do you think would be best

This is a copy and paste from someone over on BF. I thought it was a good question. I'm leaning towards 4V/Vanadis 4E due to the toughness and wear resistance required, M4 heat treated for toughness 2nd, followed by cruwear/PD1/3V. What do you guys think?

"I work in a chemical plant, and routinely have to cut into industrial insulation to inspect the equipment behind it. Tin snips are good but they leave a jagged cut. A knife leaves a much cleaner cut. I'm looking for a steel that will give me the most cuts in between sharpening. Currently I use a Cold Steel American Lawman (AUS8), a Buck csar-t (ATS-34), and a ZT 0561(Elmax). I love the lawman's thinner hollow grind blade. Maybe I should pick up the CTS XHP version.

From what I've read, my two best options are m390 and m4. what do you guys think?

I would be cutting through one to two layers of thin sheet metal and whatever material is insulating. Sometimes it's hard sheetrock material and sometimes it's a pumice type material. Any steel can do this. I'm looking for longevity.

Thanks"

And yes, I'm cross posting here just to hear what Cliff and some other people think that don't/can't post on BF.

"I work in a chemical plant, and routinely have to cut into industrial insulation to inspect the equipment behind it. Tin snips are good but they leave a jagged cut. A knife leaves a much cleaner cut. I'm looking for a steel that will give me the most cuts in between sharpening. Currently I use a Cold Steel American Lawman (AUS8), a Buck csar-t (ATS-34), and a ZT 0561(Elmax). I love the lawman's thinner hollow grind blade. Maybe I should pick up the CTS XHP version.

From what I've read, my two best options are m390 and m4. what do you guys think?

I would be cutting through one to two layers of thin sheet metal and whatever material is insulating. Sometimes it's hard sheetrock material and sometimes it's a pumice type material. Any steel can do this. I'm looking for longevity.

Thanks"

And yes, I'm cross posting here just to hear what Cliff and some other people think that don't/can't post on BF.

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: which steel do you think would be best

Lets take a look at what we need, to start :

Impact toughness is of no benefit here as the knife isn't going to take any impact, corrosion resistance also isn't an issue and thus we don't need high impact toughness or corrosion resistance. Now what do we need/want? A steel which has high strength and wear resistance to reduce rolling/deformation and wear. As there is metal being cut, a high adhesive wear resistance is desired.

Now you might be inclined to say that you need chip resistance however because there is no strict demand for a very high cutting ability, the chip resistance can be obtained simply by adjusting the edge geometry so that it has enough stability so that the apex will not suffer carbide tear out.

The last thing is that the required sharpness is really low. Gypsum board and sheet metal can be, and in fact typically are cut with blades so dull they won't pass many sharpness tests that are typically discussed. Even fibreglass insulation can be cut with very dull blades.

Now what does all of this mean, look for :

-a very high hardness in ideally a HSS (as it is very easy to get high martensite fraction)

-a very high carbide fraction

and then adjust the edge to ensure it doesn't chip and is the minimal apex and edge angle and then minimize the edge thickness and then primary grind as this will enhance performance strongly.

A few candidates would be - M4 as a readily available steel or ideally something like Maxamet or 121REX. If you have access to a custom maker you could get a very decent knife even from something as simple as 1095 at 67 HRC. Alvin Johnson used to do comparisons of 1095/67 HRC on exactly that type of work (trimming metal) and noting how strongly it would out perform something like ATS-34/60+ HRC by Paul Bos.

The critical part is however to adjust the edge so that it doesn't chip and has the minimal configuration. This has an even bigger influence than the steel.

Impact toughness is of no benefit here as the knife isn't going to take any impact, corrosion resistance also isn't an issue and thus we don't need high impact toughness or corrosion resistance. Now what do we need/want? A steel which has high strength and wear resistance to reduce rolling/deformation and wear. As there is metal being cut, a high adhesive wear resistance is desired.

Now you might be inclined to say that you need chip resistance however because there is no strict demand for a very high cutting ability, the chip resistance can be obtained simply by adjusting the edge geometry so that it has enough stability so that the apex will not suffer carbide tear out.

The last thing is that the required sharpness is really low. Gypsum board and sheet metal can be, and in fact typically are cut with blades so dull they won't pass many sharpness tests that are typically discussed. Even fibreglass insulation can be cut with very dull blades.

Now what does all of this mean, look for :

-a very high hardness in ideally a HSS (as it is very easy to get high martensite fraction)

-a very high carbide fraction

and then adjust the edge to ensure it doesn't chip and is the minimal apex and edge angle and then minimize the edge thickness and then primary grind as this will enhance performance strongly.

A few candidates would be - M4 as a readily available steel or ideally something like Maxamet or 121REX. If you have access to a custom maker you could get a very decent knife even from something as simple as 1095 at 67 HRC. Alvin Johnson used to do comparisons of 1095/67 HRC on exactly that type of work (trimming metal) and noting how strongly it would out perform something like ATS-34/60+ HRC by Paul Bos.

The critical part is however to adjust the edge so that it doesn't chip and has the minimal configuration. This has an even bigger influence than the steel.

Re: which steel do you think would be best

What do you think of M390, S90V, or other high carbide steels? I think they'd be terrible for the job. Since 4V was designed for high adhesive wear jobs, I'd think that would be ideal, but again, relatively hard to obtain. By high carbide fraction do you mean high carbide volume finely disbursed?

And I said toughness but I should've said lateral strength to keep the edge from rolling easily without being brittle. I would also think the higher than normal retained austenite would help in this application.

And I said toughness but I should've said lateral strength to keep the edge from rolling easily without being brittle. I would also think the higher than normal retained austenite would help in this application.

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: which steel do you think would be best

Bodog,

4V is essentially a cold work version of M4, or more precisely a less hot work as it still has a strong secondary hardening response, just slightly less than M4. How strong a hardening response, well just look at this :

- https://drive.google.com/file/d/0B3dKJo ... sp=sharing" onclick="window.open(this.href);return false;

The reason all those tempers were done was to get the hardness down to ~62 HRC, the primary tempers left it at 64 HRC.

Would 4V be superior to M4? i don't see why it would, however it isn't like M4 is going to be significant superior either. I can't see how 4V would be superior to 10V in that application as there is no impact and thus the greater impact toughness has no use so 4V is just weaker and less abrasion resistant. Maxamet and 121REX take that one step further still. 121REX is a pretty interesting material at low sharpness because at ~70 HRC with a huge carbide volume fraction it can do some pretty interesting things. I can take a 121REX knife for example and draw it right across a sharpening stone, edge first, and the apex won't reflect light. The high sharpness goes rapidly, I assume through some kind of micro-fracture, but to get it beyond 20 microns thick (which is where I can see it reflect light) takes a lot of work. Of course ideally you would just use a ceramic or carbide blade, adjust the geometry and keep all loads in compression.

I don't see why you would think S90V would be horrible but 4V would be great, exactly what are you thinking about there?

I just mean a lot of carbide, yes, ideally it should be well dispersed, any aggregates tend to be detrimental unless you are looking for some kind of self-fracturing effect which I don't think would be useful here.

4V is essentially a cold work version of M4, or more precisely a less hot work as it still has a strong secondary hardening response, just slightly less than M4. How strong a hardening response, well just look at this :

- https://drive.google.com/file/d/0B3dKJo ... sp=sharing" onclick="window.open(this.href);return false;

The reason all those tempers were done was to get the hardness down to ~62 HRC, the primary tempers left it at 64 HRC.

Would 4V be superior to M4? i don't see why it would, however it isn't like M4 is going to be significant superior either. I can't see how 4V would be superior to 10V in that application as there is no impact and thus the greater impact toughness has no use so 4V is just weaker and less abrasion resistant. Maxamet and 121REX take that one step further still. 121REX is a pretty interesting material at low sharpness because at ~70 HRC with a huge carbide volume fraction it can do some pretty interesting things. I can take a 121REX knife for example and draw it right across a sharpening stone, edge first, and the apex won't reflect light. The high sharpness goes rapidly, I assume through some kind of micro-fracture, but to get it beyond 20 microns thick (which is where I can see it reflect light) takes a lot of work. Of course ideally you would just use a ceramic or carbide blade, adjust the geometry and keep all loads in compression.

I don't see why you would think S90V would be horrible but 4V would be great, exactly what are you thinking about there?

I just mean a lot of carbide, yes, ideally it should be well dispersed, any aggregates tend to be detrimental unless you are looking for some kind of self-fracturing effect which I don't think would be useful here.

Re: which steel do you think would be best

CPM-CRUWEAR is a decent option IMO.

Re: which steel do you think would be best

I was thinking 4V would be slightly better because of the retained austenite percentage along with the adhesive wear resistance. In my mind, I'm definitely not an expert and cannot come close to claiming to be one, the high hardness it's capable of combined with the what, 20% RA that 4V has after temper, would keep the apex from fracturing and also resist rolling. I believe, though I've never talked to him and this is a complete assumption, that's why Keffeler was successful in using 4V/Vanadis 4E while others were and are still using M4.Cliff Stamp wrote:Bodog,

4V is essentially a cold work version of M4, or more precisely a less hot work as it still has a strong secondary hardening response, just slightly less than M4. How strong a hardening response, well just look at this :

- https://drive.google.com/file/d/0B3dKJo ... sp=sharing" onclick="window.open(this.href);return false;

The reason all those tempers were done was to get the hardness down to ~62 HRC, the primary tempers left it at 64 HRC.

Would 4V be superior to M4? i don't see why it would, however it isn't like M4 is going to be significant superior either. I can't see how 4V would be superior to 10V in that application as there is no impact and thus the greater impact toughness has no use so 4V is just weaker and less abrasion resistant. Maxamet and 121REX take that one step further still. 121REX is a pretty interesting material at low sharpness because at ~70 HRC with a huge carbide volume fraction it can do some pretty interesting things. I can take a 121REX knife for example and draw it right across a sharpening stone, edge first, and the apex won't reflect light. The high sharpness goes rapidly, I assume through some kind of micro-fracture, but to get it beyond 20 microns thick (which is where I can see it reflect light) takes a lot of work. Of course ideally you would just use a ceramic or carbide blade, adjust the geometry and keep all loads in compression.

I don't see why you would think S90V would be horrible but 4V would be great, exactly what are you thinking about there?

I just mean a lot of carbide, yes, ideally it should be well dispersed, any aggregates tend to be detrimental unless you are looking for some kind of self-fracturing effect which I don't think would be useful here.

I would think that the apex weakness, i.e. carbide tearout and fracture rate, would leave S90V and M390 etc. blunting at an extremely high rate and any kind of torsional stress which would come from cutting sheet metal would be quick to turn his blade into a butter knife.

And thank you for correcting my use of disburse vs disperse.

They who dance are thought mad by those who do not hear the music.

- Surfingringo

- Member

- Posts: 5824

- Joined: Sun Sep 01, 2013 2:02 pm

- Location: Costa Rica

Re: which steel do you think would be best

Very interesting (and civil) discussion. Blerv would be proud of us!! :D

I can definitely find relevancy in the discussion as I feel like my use on fish is not so different than the example you guys are discussing. I believe most of my dulling comes from higher force cuts into scales and bone which i guess would be somewhat analogous to the sheet metal. I have not used a huge number of steels in this activity but i can say that I have been very happy with the performance I get out of m4. I definitely prefer it to s30v. I also prefer it to the s90v I have but thats in a different knife from a different maker with a different ht, so.....

I can definitely find relevancy in the discussion as I feel like my use on fish is not so different than the example you guys are discussing. I believe most of my dulling comes from higher force cuts into scales and bone which i guess would be somewhat analogous to the sheet metal. I have not used a huge number of steels in this activity but i can say that I have been very happy with the performance I get out of m4. I definitely prefer it to s30v. I also prefer it to the s90v I have but thats in a different knife from a different maker with a different ht, so.....

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: which steel do you think would be best

4V has a very strong secondary hardening response, with the normal cycles people run the RA % is likely 5% or less. Retained austenite is also really soft/weak, it would tend to lower resistance to rolling.Bodog wrote:

[...] 20% RA that 4V has after temper, would keep the apex from fracturing and also resist rolling.

Retained austenite in steels is dependent on the steels, meaning that some steels typically will have high/low RA, however it is really strongly influenced by how the steel is hardened.

If a steel has a strong secondary hardening response (high Cr, Mo, W) then the RA can be minimized through hot tempering. Otherwise, RA can usually be minimized by deep cooling.

This is why I noted the geometry has to be critical. While apex stability is a property of the material, the apex stability of a tool is not only dependent on the steel but also the geometry. It is likely that 4V would be able to take a thinner cross section and prevent tear out than S90V, however as there was no constraint for a very high cutting ability or sharpness then it should be possible to adjust the apex angle to prevent carbide tear out. Ideally use plateau sharpening to leave a small flat on the edge initially.I would think that the apex weakness, i.e. carbide tearout and fracture rate, would leave S90V and M390 etc. blunting at an extremely high rate and any kind of torsional stress which would come from cutting sheet metal would be quick to turn his blade into a butter knife.

In regards to adhesive wear resistance, it need to be realized that this is a paired property. This means that the adhesive wear resistance of a material depends on what it is sliding against. For example the adhesive wear resistance of D2 is very low when in contact with stainless steel because of the infinity of chrome to chrome. This is not the case against all materials. Here is a decent paper on adhesive wear of a number of tool steels :

- http://t.tribologia.eu/trib/artykul/201 ... 47-058.pdf" onclick="window.open(this.href);return false;

Re: which steel do you think would be best

Interesting discussion. Thanks Bodog for keeping it going and Cliff for really informative answers.

I can't say I have put my knives to the uses described by the OP, or anything like what SurfingGringo does, but I have been very happy with spyderco's M4 and S90V for a lot of cutting of 1/2" and 3/4" horsestall mats and industrial conveyor belts. Cutting these dense mats requires a lot of downward force to get a cut deep enough and these two steels are the only ones I have tried that just keep cutting without needing constant sharpening. PM2 and Mili for the S90V and Manix2 for M4. I have not tried my Cruwear mili for this chore yet, but I have a feeling it will do ok. Also have not tried my BM Contego in M4. I have tried other PM2s in M390 and 204p and neither do as well as the S90V. Just observations based on use, no theory. My strategy when I'm doing stuff like this and the knife stops cutting well... switch knives, sharpen later

I can't say I have put my knives to the uses described by the OP, or anything like what SurfingGringo does, but I have been very happy with spyderco's M4 and S90V for a lot of cutting of 1/2" and 3/4" horsestall mats and industrial conveyor belts. Cutting these dense mats requires a lot of downward force to get a cut deep enough and these two steels are the only ones I have tried that just keep cutting without needing constant sharpening. PM2 and Mili for the S90V and Manix2 for M4. I have not tried my Cruwear mili for this chore yet, but I have a feeling it will do ok. Also have not tried my BM Contego in M4. I have tried other PM2s in M390 and 204p and neither do as well as the S90V. Just observations based on use, no theory. My strategy when I'm doing stuff like this and the knife stops cutting well... switch knives, sharpen later

Last edited by dogrunner on Tue May 05, 2015 10:03 am, edited 1 time in total.

Re: which steel do you think would be best

Tried uploading the material data sheet from BU for V4E. Won't let me do it for some reason. It shows significantly more RA than 5% at normal hardnesses for knives. And I wasn't trying to say that RA kept the knife from rolling. I tried to say and probably failed to say that the high RA would keep the edge from fracturing combined with the ability to reach high hardness to keep the edge from rolling, would be a good combination.

I don't know how they make a steel with significant RA that can also be taken to high hardness, but they do and I don't believe they can outright lie and remain in business very long. It's not like a generic statement such as "I'm crazy so I have CARAZY prices!" It's a pretty specific statement as to the material's properties.

And I'd think a steel designed for cold work would be better at cold work than a steel designed hot work with a high red hardness. But that's just speculation on my part.

I believe that 4V/V4E were designed specifically for the application of cutting soft metal at room temperature +/-. I could be wrong. That along with higher than normal abrasion resistance to tackle the particulates in the insulation materials has me thinking that 4V/V4E would have the best property balance. It's all speculation, though. I look at the data and form a hypothesis but without the materials to test it's all academic.

I don't know how they make a steel with significant RA that can also be taken to high hardness, but they do and I don't believe they can outright lie and remain in business very long. It's not like a generic statement such as "I'm crazy so I have CARAZY prices!" It's a pretty specific statement as to the material's properties.

And I'd think a steel designed for cold work would be better at cold work than a steel designed hot work with a high red hardness. But that's just speculation on my part.

I believe that 4V/V4E were designed specifically for the application of cutting soft metal at room temperature +/-. I could be wrong. That along with higher than normal abrasion resistance to tackle the particulates in the insulation materials has me thinking that 4V/V4E would have the best property balance. It's all speculation, though. I look at the data and form a hypothesis but without the materials to test it's all academic.

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: which steel do you think would be best

Are you talking about this :Bodog wrote:

I don't know how they make a steel with significant RA that can also be taken to high hardness, but they do and I don't believe they can outright lie and remain in business very long.

- http://www.uddeholm.com/files/PB_Uddeho ... nglish.pdf" onclick="window.open(this.href);return false;

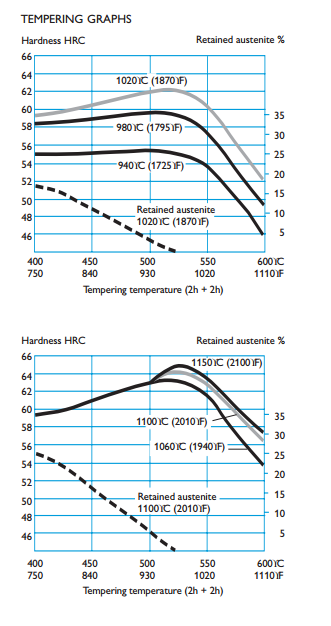

The graph which shows the high retained austenite is looking at the state of the steel as quenched, without deep cooling and without tempering. This is why both the RA and hardness drops as the soak temperature is increased.

Look at the graphs to the right which show the steel in the final state after tempering. The typical temperatures for tempering 4V will leave it with < 5% RA. Note how the hardness now increases as the soak temperature increases.

The same very low RA could also like be obtained with deep cooling.

Re: which steel do you think would be best

I guess I may be looking at the graphs wrong but it looks to me that at the recommended austenizing temperature and time there's about 35% RA and after temper at the recommended temperature and time there's about 15% depending on final hardness.

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: which steel do you think would be best

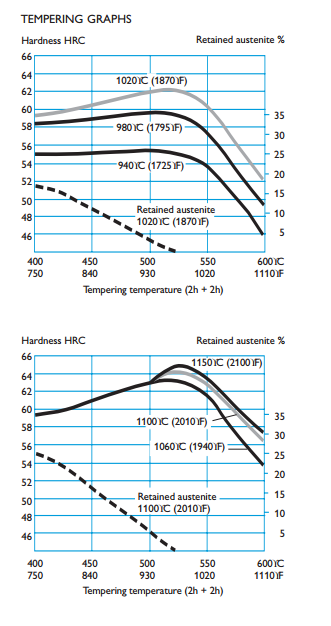

Here is the tempering graph :

A few details on interpreting the graphs :

-the dashed lines are the retained austenite levels, the axis for them is on the right hand side

-the solid lines are the hardness levels, the axis for them is on the left hand side

Note the above hardening report I linked to for 4V which was done on current mid-tech knife blades (Ferrum Forge) :

-austenite 2100

-temper 975

This produces a hardness of ~64 HRC and a retained austenite of ~0%, i.e., no retained austenite. This happens because this hits the secondary hardening peak with causes a strong carbide precipitation level which lowers the austenite alloy composition, raises the Mf point and thus that austenite converts to martensite in the quench after the tempering. This is why you always have to do multiple high tempers .

A few details on interpreting the graphs :

-the dashed lines are the retained austenite levels, the axis for them is on the right hand side

-the solid lines are the hardness levels, the axis for them is on the left hand side

Note the above hardening report I linked to for 4V which was done on current mid-tech knife blades (Ferrum Forge) :

-austenite 2100

-temper 975

This produces a hardness of ~64 HRC and a retained austenite of ~0%, i.e., no retained austenite. This happens because this hits the secondary hardening peak with causes a strong carbide precipitation level which lowers the austenite alloy composition, raises the Mf point and thus that austenite converts to martensite in the quench after the tempering. This is why you always have to do multiple high tempers .

Re: which steel do you think would be best

Got it, I was reading it wrong.

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: which steel do you think would be best

My brother keeps horses and uses a serrated H1 folder for that. I would be curious how you would find that if you had the chance.dogrunner wrote:... I have been very happy with spyderco's M4 and S90V for a lot of cutting of 1/2" and 3/4" horsestall mats and industrial conveyor belts

Re: which steel do you think would be best

Well you are saying 2 different things- "keep the edge from rolling" means you want strength, i.e. hardness. "without being brittle" means you want toughness. Unfortunately there is a tradeoff, you can't have both properties. You can't have an edge that won't roll AND won't be brittle. You pick the combination of steel, heat treat and geometry that will put the point of the tradeoff where it benefits you most.Bodog wrote:And I said toughness but I should've said lateral strength to keep the edge from rolling easily without being brittle. I would also think the higher than normal retained austenite would help in this application.

I agree with the recommendation for M4.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: which steel do you think would be best

All steels have a plastic region where they will deform, and then a point at which they break/rupture. There are compositions and heat treatments which increase the point at which steels deform and decrease the plastic region (they deform very little before they rupture). However there are compositions and heat treatments which increase both at the same time. The steel both gets harder and stronger and gets more ductile and will bend further before it breaks.bdblue wrote: You can't have an edge that won't roll AND won't be brittle.

This is also strongly influenced by geometry. As an edge cross section get lower it will tend to deform and not break even if it would have broken at a similar roll at a thicker cross section. This is because the internal strain is higher at a given bend extent based on the cross section (due to the difference between compression and tensile stresses on the inside/outside of the bend). This is why very thin blades can bend readily and not snap. Phil Wilson noted for example he could even bend a S90V fillet blade tip to 90 degrees and not break. Now this doesn't mean S90V is very ductile, it just means he grinds very thin tips.

Re: which steel do you think would be best

I have an Atlantic salt - serrated H1. Did not occur to me to try it but the sheepsfoot blade shape should work well for slicing into mats. I'll be doing a lot of kennel maintenance this summer (we use the mats in dog kennels) so I'll find out how the H1 compares.Cliff Stamp wrote: My brother keeps horses and uses a serrated H1 folder for that. I would be curious how you would find that if you had the chance.