He really helped me out when I had a knife blade where the edge was backwards, pointing up when I wanted it pointing down, or vice versa.Surfingringo wrote:It's actually Cliff's "material" but I always get a good chuckle out of it so I thought I'd steal it. I don't know if yall have noticed but ole Cliff makes a pretty good funny every now and then.

Re: SE Military 440v vs s30v

Re: Re: SE Military 440v vs s30v

Re: Re: SE Military 440v vs s30v

OH I"m here "TBD" :D I am watching this thread intently I can assure youtwinboysdad wrote:Sort of surprised JD hasn't jumped in here? There has to be some members with SE 440v and s30v that have an opinion

And NO!!! I haven't had any of the teeth chip or break even after torturous cutting jobs I've done with it in the past 7 years or so. Now there is one thing I do complain about 440V and that is the fact that it is a literal monster to sharpen :eek: I"ve found 440V to be much harder to sharpen than even S90V, ZDP-189 or even XHP.

I can't hardly sharpen any 440V blade without cursing out loud at some point during the job :rolleyes: :D I guess it must be the vanadium content that makes it a monster to sharpen>> but that's probably something Cliff could tell us more in detail. But if they would bring back the Military, ParaMilitary, Native and other Spyderedged blades in 440V I will be standing in line for some of the first ones I can assure you :cool:

-

twinboysdad

- Member

- Posts: 3719

- Joined: Tue Mar 26, 2013 6:23 pm

Re: Re: SE Military 440v vs s30v

Harder to sharpen than ZDP? Yikes

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Re: SE Military 440v vs s30v

S60V has a tremendous amount of carbide, it is one of the hardest stainless steels to work. This is AEB-L which has 3-5% chromium carbide :twinboysdad wrote:Harder to sharpen than ZDP?

Note the very high magnification, the carbides are very small, on the order of a micron in size.

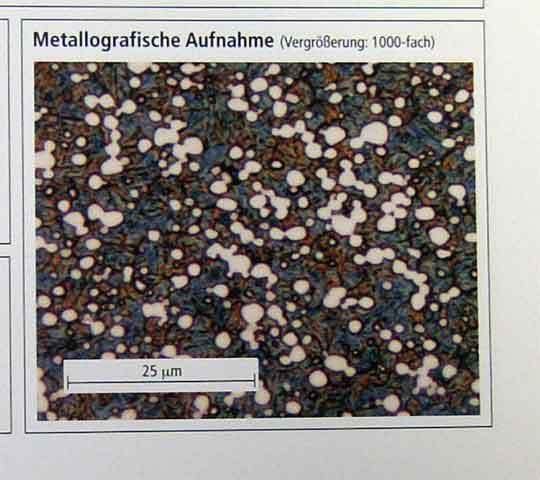

This is S60V :

The white globs are the carbides, a mix of chromium and vanadium carbide. Note the carbides are much larger than they combine in groups of about 10 microns in size.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Re: SE Military 440v vs s30v

Is the serration pattern similar to the modern ones? Can you take a picture of it?JD Spydo wrote:And NO!!! I haven't had any of the teeth chip or break even after torturous cutting jobs I've done with it in the past 7 years or so.

Re: Re: SE Military 440v vs s30v

Sorry Cliff I don't presently have any way of putting up a picture unforunately. But the serration pattern is very similar to all the other Spyderedges that are made in the Golden CO USA Spyderco plant. I've had quite a few of the Golden CO made serrated Spyders from the late 90s to the mid 2000 decade and most of the USA Spyderco patterns are very similar IMO. The serrations on most of the Spyderco Japan made Spyders for instance are a lot more "spikey" whereas the GOLDEN USA Spyderco serrations have a bit more of a rounded/wavy type and a lot less "spikey" than the ones from Japan are.Cliff Stamp wrote:Is the serration pattern similar to the modern ones? Can you take a picture of it?JD Spydo wrote:And NO!!! I haven't had any of the teeth chip or break even after torturous cutting jobs I've done with it in the past 7 years or so.

No I attribute the super performance to the fact that 440V (S60V) just seems to be a lot tougher and more rugged than many other blade steels that Spyderco has used throughout their history. We've sort of had this conversation before on another thread in the past 2 months concerning what we deem as an ideal steel for serrations and I went on record then saying that some of my favorite blade steels for Spyderedges are ATS-55, AUS-8, 440V and to some extent I had fairly good luck with the older GIN-1 (G-2) serrations. Also I pointed out on that thread that most of the steels I found good for plain edges are not the best for serrations and vice-versa. ZDP-189 for instance seems to be a supersteel for plain edges and Spyderco themselves admit that it isn't that great for Spyderedges unfortunately.

H-1 is said to be their best Spyderedged blade steel but we all know that it's far from being the best PE steel>> even though it is fairly easy to sharpen.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Re: SE Military 440v vs s30v

JD, no worries. Just by looking at it, are the angles/thickness of the teeth similar as well?

-

twinboysdad

- Member

- Posts: 3719

- Joined: Tue Mar 26, 2013 6:23 pm

Re: Re: SE Military 440v vs s30v

I have had this conversation with WireEdge Roger, as neither of us are crazy about the H1 SE Dragonfly because the teeth are just too "snaggy". We both prefer the shallower Pac Salt teeth in H1.

Re: Re: SE Military 440v vs s30v

Yeah that's exactly what I was trying to get across to Cliff>> because with most of my Japan made serrated Spyders I've discovered during hard use that the Japan made serrations are indeed more spikey and do indeed snag on most fibrous materials>> considerably more than I've had the serrated Spyders made in the Golden CO USA Spyderco plant. And I do agree with Cliff that when you look at them in a picture or website they do look similar but when you use them you'll see immediately what I'm talking about because the spike part of the serration on the Japan made Spiders is like an ice pick compared to the GOLDEN USA made counterparts>> and trust me I've used a lot of Spyderco's serrated blades over the years going all the way back to the GIN-1 Spyderedged models>> so I've had a lot to compare with.twinboysdad wrote:I have had this conversation with WireEdge Roger, as neither of us are crazy about the H1 SE Dragonfly because the teeth are just too "snaggy". We both prefer the shallower Pac Salt teeth in H1.

But concerning 440V for serrated edges that steel just seems to be of a dense and tough material property that it endures hard use for Spyderedges better than about any other blade steel I've used in Spyderco's line up>> albeit but 440V isn't nearly as good as some of Crucibles other steels in plain edge. But even more strange than that is the super tough properties I've found using the old AUS-8 serrated Spyders>> which most people will agree isn't all that great for plain edges and most certainly worse than 440V.

I would love to try out a serrated Hawkbill made with 440V>> or even a serrated recurve made with it for that matter.

Last edited by JD Spydo on Fri Mar 27, 2015 6:22 am, edited 1 time in total.

-

twinboysdad

- Member

- Posts: 3719

- Joined: Tue Mar 26, 2013 6:23 pm

Re: Re: SE Military 440v vs s30v

Has Sal checked in? Mike Janich? Taz?

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Re: SE Military 440v vs s30v

Just to confirm, when you make the above you are saying that you have seen significant damage in the SpyderEdges in the same type of work with other Spyderco steels?JD Spydo wrote:

But concerning 440V for serrated edges that steel just seems to be of a dense and tough material property that it endures hard use for Spyderedges better than about any other blade steel I've used in Spyderco's line up>> albeit but 440V isn't nearly as good as some of Crucibles other steels in plain edge.

Re: Re: SE Military 440v vs s30v

Cliff Stamp wrote:I don't know who started that but I saw Thom Brogan do it first. Before Crucible's promotion of MC/vanadium carbides, most discussions on steels were balanced. You would see things like how 1084 vs D2 was an if/then type comparison as to which one should be used in a given situation. In a short period of time the discussions seemed to be similar to the old discussions on edge packing in forging.

A lot of arguments would be similar to - such a steel is a poor choice as it lacks vanadium bro. Brogan was the first guy I saw make that kind of remark and also note the name was critical as well, hence something like HAP 40 is a much better steel than M4. It isn't even a question, a child knows that 40 HAP's is way bigger than 4 M's.

440V is lame anyway, I may be getting a piece of 20V which shames even 10V. As far as I know that has the most V out of any steel.

It would be curious to see S60V compared to m390/Elmax, as it is a similar type of steel, high vanadium, high chromium steel.

Why do you think 440V is lame, Cliff?

:spyder: MEMBRE DE L'ORDRE INTERNATIONALE SPYDEREDGE :spyder:

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Re: SE Military 440v vs s30v

Joke, it was funny to me, likely not to anyone else reading it.D-Roc wrote:

Why do you think 440V is lame, Cliff?

Thom Brogan made similar jokes a few years ago when it sort of became a popular argument for people to look at a steel, see that it had a lot of elements in it and then conclude that made it better and the more things in it the better it was.

That was why I referenced 20V after it which has the higher vanadium carbide out of any regular steel. Now to be clear there are much higher carbide steels even above 20V. There are metal matrix composites for example which take steels and then fill them full of reclaimed carbides so the volume fraction can be ~double 20V. However at some point these stop really being steels by any reasonable definition of steel.

440V/S60V is a curious steel because the only real arguments against it was that it was impossible to grind/polish and harden and even custom makers complained about it. However there are many steels currently used on knives even in the production level which are more difficult in all respects. It just shows you how much the industry has advance in using modern alloys in just a few years.

Just think about the fact that Spyderco is now using knives that a few years back even custom knifemakers would not readily use.

Re: Re: SE Military 440v vs s30v

I've always liked it. I think I have maybe ten Spyderco's, with it. Really tough for me to follow everyone in the great ongoing steel debate because I'm a child of the "The Golden Era"...98-03. Plus, ergos, feel and reliability always trump a steel choice for me.

I hadn't heard too many complaints performance wise, hence my question.

I don't recall everyone being so concerned/interested/particular about steel 15 years ago.

I hadn't heard too many complaints performance wise, hence my question.

I don't recall everyone being so concerned/interested/particular about steel 15 years ago.

:spyder: MEMBRE DE L'ORDRE INTERNATIONALE SPYDEREDGE :spyder:

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Re: SE Military 440v vs s30v

It was very different in the 90's.D-Roc wrote: I don't recall everyone being so concerned/interested/particular about steel 15 years ago.

On one of the main knife-lists, which predate the forums, the question was asked which steel would they use for their personal knives, what is the best steel for knives if just the purpose was considered. The answer was very consistent in 50100-B, a very simple low alloy steel.

A lot of the importance of steel is grossly distorted. Ask a carpenter the last time he thought about the steel that was used to make the hammer in his pouch. And even more so, do the best carpenters know the most about that question?

I have knives in lots of steels, but in general when I pick knives for use, steel is one of the last things I consider unless it is a really odd choice like a machete in S110V or similar.

Re: Re: SE Military 440v vs s30v

I've never owned a SE Spyderco that was made in the Golden plant, all of mine are from Japan. I definitely concur that the less spiky serrations work better for me.

Re: Re: SE Military 440v vs s30v

Yes actually I have seen other Spyderco blade steels not hold up to punishment as good as 440V or even ATS-55 for that matter. Now I've never used a serrated ZDP-189 Spyderco blade but I have talked to and read posts here on the forum from several other forum members who have had bad results from using that particular blade steel in SE>> and it's my understanding that Spyderco has no plans on making anymore serrated blades with ZDP-189 from what I've been told.Cliff Stamp wrote:Just to confirm, when you make the above you are saying that you have seen significant damage in the SpyderEdges in the same type of work with other Spyderco steels?JD Spydo wrote:

But concerning 440V for serrated edges that steel just seems to be of a dense and tough material property that it endures hard use for Spyderedges better than about any other blade steel I've used in Spyderco's line up>> albeit but 440V isn't nearly as good as some of Crucibles other steels in plain edge.

As much as I love VG-10 steel overall I've had Spyderedges on VG-10 blades dull a lot easier than I have on 440V for example. Now I've never had chipped teeth or any tip breakage on VG-10 Spyderedged blades but I have heard others saying as much. Even using the older GIN-1 serrated Spyders I've had better luck with that blade steel than I have with some of the newer ones>> the same can be said with AUS-8 and ATS-55.

Now Spyderco claims that H-1 has done better in Spyderedge than with other blade steels they tested. And I've used my H-1 SE Spyderhawk a lot with no significant damage to speak of. I just know in my gut and with my past results in using them that there are blade steels that seem to have more of a toughness property to them that seem to perform better in Spyderedge but that's just my own personal results using them>> it's honest to say that I've done no scientific testing to prove that but in my gut I know steels like 440V just hold up better>> but again I don't regard 440V as being a premium steel for plain edges but the same can be said for H-1.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Re: SE Military 440v vs s30v

So when you talk about the edge being tough you are talking about it resisting wear strongly not resisting chipping / breaking? That is what you would expect as it has a very high carbide volume.JD Spydo wrote: As much as I love VG-10 steel overall I've had Spyderedges on VG-10 blades dull a lot easier than I have on 440V for example. Now I've never had chipped teeth or any tip breakage on VG-10 Spyderedged blades [...]

Re: Re: SE Military 440v vs s30v

Well it goes a little deeper than that >> because it's like a talk we had some time back about blade steels that are more noted for toughness rather than edge retention on a plain edge for instance. Because again I've had better luck with steels that I've used in Spyderedge not being all that good for plain edged blades but for some strange reason they do tend to hold up good with a serrated edge. When I heard Spyderco say that H-1 was up to that time the best steel for Spyderedges that they had tested I literally couldn't hardly believe it at first. Because I had owned and used 3 different plain edged, H-1 Salt blades and two of them PE Hawkbills. And to tell you the truth I wasn't impressed at all with the edge retention at all compared to let's say VG-10, D-2 or even XHP for that matter which are three steels I've had good luck with on plain edged blades.Cliff Stamp wrote:So when you talk about the edge being tough you are talking about it resisting wear strongly not resisting chipping / breaking? That is what you would expect as it has a very high carbide volume.JD Spydo wrote: As much as I love VG-10 steel overall I've had Spyderedges on VG-10 blades dull a lot easier than I have on 440V for example. Now I've never had chipped teeth or any tip breakage on VG-10 Spyderedged blades [...]

But with Spyderedges or Spyderco's serrated kitchen knives it seems like steels with other properties tend to do better. Like I have testified before when I worked in that automotive mod shop and I had a job where I was going to have to remove a lot of wire and other tough materials I resigned myself to the fact that I was going to probably destroy a blade in order to get this job done. I had a 440V, SE Native I had in my footlocker that I got from a trade a few years back and I had literally forgot I even had the knife. So I was prepared to use it as a "sacrificial lamb" so to speak and I knew in my gut I was going to pretty much destroy the knife all together. But much to my most pleasant surprised the knife held up exceptionally well and I was really impressed with the 440V Spyderedged blade and with a thorough sharpening the blade and the folder's mechanisms were in great shape when I was done.

So what I'm saying is I'm personally finding blade steels that are more noted for toughness that seem to be better performing in a serrated blade. Also I've used my older AUS-8 full SE Catcherman about as much as I've used any of my Spyderco knives and I've used that AUS-8 full SE CATCHERMAn on some pretty demanding jobs and that blade steel holds up great>> but again I've had some Spyders in plain edge with AUS-8 that I wasn't that impressed with unfortunately compared to VG-10 which I've always found to be good in PE.

I've had similar results with two ATS-55 Spyderedged blades that I've used a lot but in plain edge I find ATS-55 to be slightly above average for the most part. Even GIN-1 I've had good luck with in Spyderedge. It seems to me that steel with toughness properties I'm finding to be the best. But I did have a GIN-1 serrated Endura have teeth chip on me on at least two occasions. It takes some really radical abuse to chip teeth from my experiences.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Re: SE Military 440v vs s30v

Imagine someone said that 1095 was really corrosion resistant. If you found this curious and asked for details they said they found it very easy to grind and could sharpen it even with Arkansas stones. Now their observations are not false, and their conclusions are not strictly invalid, but what they mean when they say corrosion resistant is not what the words mean in a materials sense.JD Spydo wrote: So what I'm saying is I'm personally finding blade steels that are more noted for toughness that seem to be better performing in a serrated blade.

A tough steel, speaking of metallurgy, is one which resists fracture, it doesn't mean tough as in the lay sense which often just means difficult (that guy is tough to deal with). If for example you used a VG-10 serrated blade and you noted it chipped and the teeth snapped off and then you used a 440V one, in a similar geometry and it didn't fracture, then that would be demonstrating toughness.

However if you use a 440V blade and a VG-10 blade and you see a lot less wear on the 440V blade and that it holds up in regards to holding a higher sharpness in cutting very abrasive and hard materials, and neither blade chips/fractures, this isn't demonstrating toughness in the materials sense, it is demonstrating wear resistance, a completely different property.

The other thing is what when you are comparing blades and drawing conclusions on steels, the cross sections have to be near identical because many of the properties of steel (strength for example) are nonlinear on cross section. For example an edge which is 0.020" is almost twice as strong as one which is just 0.015" yet most people would say they are near identical in shape. It however would take a huge jump in steel to make that kind of strength change.